Nasal prosthesis and processing method

A technology for nasal prosthesis and bridge of the nose, applied in the field of nasal prosthesis, can solve the problems of poor manual cutting precision, affecting postoperative recovery, falling off of nasal prosthesis, etc., to achieve the requirements of improving efficiency, reducing surgical difficulty and reducing carving skills Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

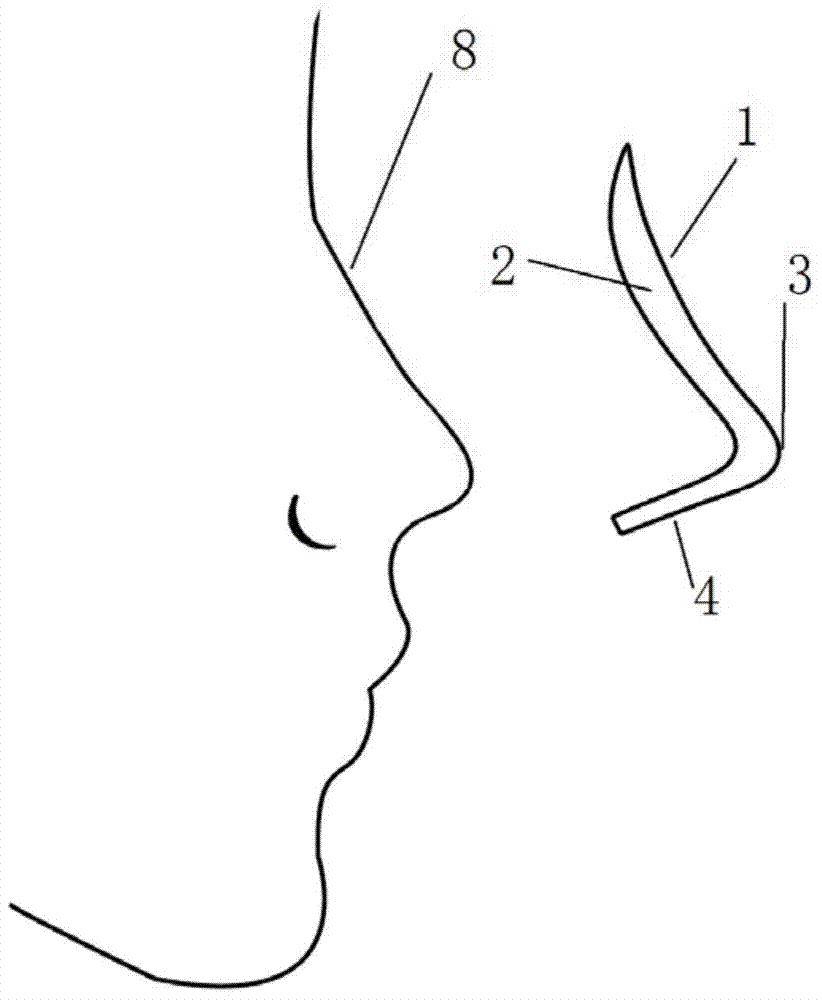

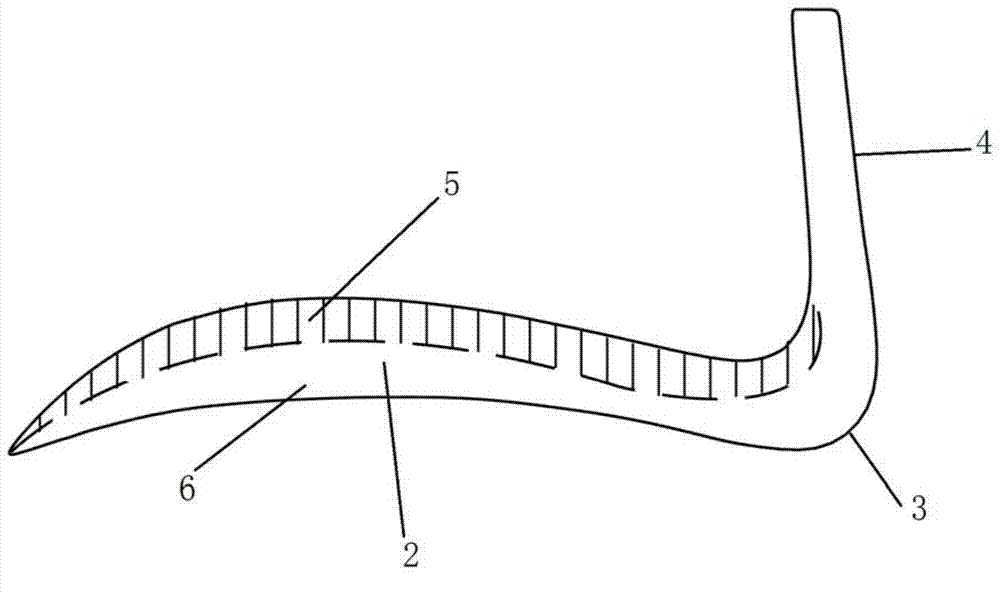

[0040] Such as image 3As shown, the nasal prosthesis 1 includes the bridge of the nose 2, the tip of the nose 3, and the columella 4. The bridge of the nose 2 is connected to the columella 4 through the tip of the nose 3. The bridge of the nose 2 includes a surface layer 6 for shaping and a fitting layer for fitting with the nose 5. The bonding layer 5 and the surface layer 6 are made of the same material. The surface layer 6 of the bridge of the nose 2 has no holes, and the bonding layer 5 has many holes 7. The bonding layer 5, which is made of the same material as the surface layer 6, becomes soft. Yes, and it is elastic, can be stretched, and can fit the nose well. There is a hole 7 that allows body fluids to flow into the hole. 7 is integrated with the nasal prosthesis 1 to prevent it from moving, festering, and postoperative pain for patients. If you want to take out the nasal prosthesis 1, because the nasal prosthesis 1 has elasticity and can be stretched, you can easil...

Embodiment 2

[0042] Such as Figure 4 As shown, the nasal prosthesis 1 includes the bridge of the nose 2, the tip of the nose 3, and the columella 4. The bridge of the nose 2 is connected to the columella 4 through the tip of the nose 3. The bridge of the nose 2 includes a surface layer 6 for shaping and a fitting layer for fitting with the nose 5. The bonding layer 5 and the surface layer 6 are made of the same material, and both the bonding layer 6 and the surface layer 6 of the bridge of the nose 2 have holes 7 of the same density. The surface layer has 6 holes and 7 depths. In this way, the bonding layer 5 is relatively soft, and the surface layer 6 is relatively hard.

[0043] The thickness of the nose bridge 2 of the nasal prosthesis 1 is uneven, so the depth setting of the hole 7 needs special treatment. We divide the thickness of the nose bridge 2 into preset layers, such as 10 layers, 20 layers, etc., so that the thickness of each part of the nose bridge 2 is different, and the l...

Embodiment 3

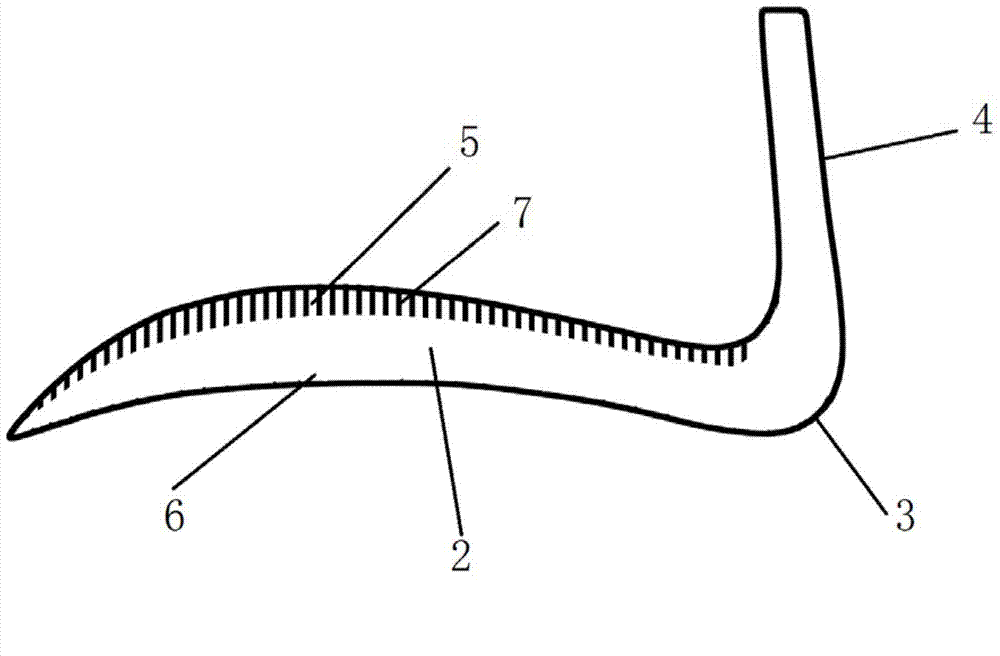

[0045] Such as Figure 5 As shown, the nasal prosthesis 1 includes the bridge of the nose 2, the tip of the nose 3, and the columella 4. The bridge of the nose 2 is connected to the columella 4 through the tip of the nose 3. The bridge of the nose 2 includes a surface layer 6 for shaping and a fitting layer for fitting with the nose 5. The fitting layer 5 and the surface layer 6 are made of the same material, the density of the holes 7 of the fitting layer 5 is greater than the density of the holes 7 of the surface layer 6, and in the area of the same thickness layer of the nasal prosthesis, the fitting layer 5 and the surface layer The skin 6 has holes 7 of the same depth.

[0046] The surface layer 6 has a hole 7 to allow body fluids to flow into the hole 7 and integrate with the nasal prosthesis to enhance its fixity and prevent the nasal prosthesis from moving. The surface layer 6 is harder than the bonding layer 5 and can play a better shaping effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com