Two-horizontal-movement one-rotation three-freedom-degree series-parallel vibrating screen

A technology of degree of freedom and vibrating screen, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of limited screening effect, uneven distribution of materials on the screen surface, less vibration freedom, etc., and achieve equipment cost and operating performance Low power consumption, improved screening efficiency, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

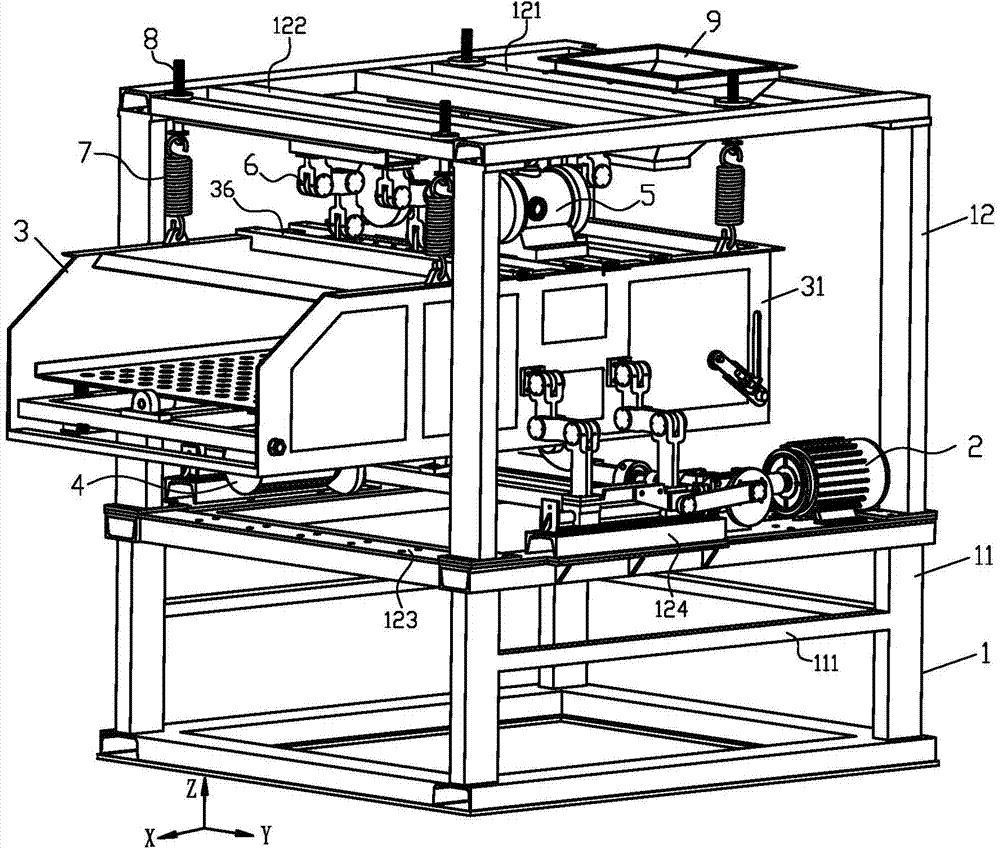

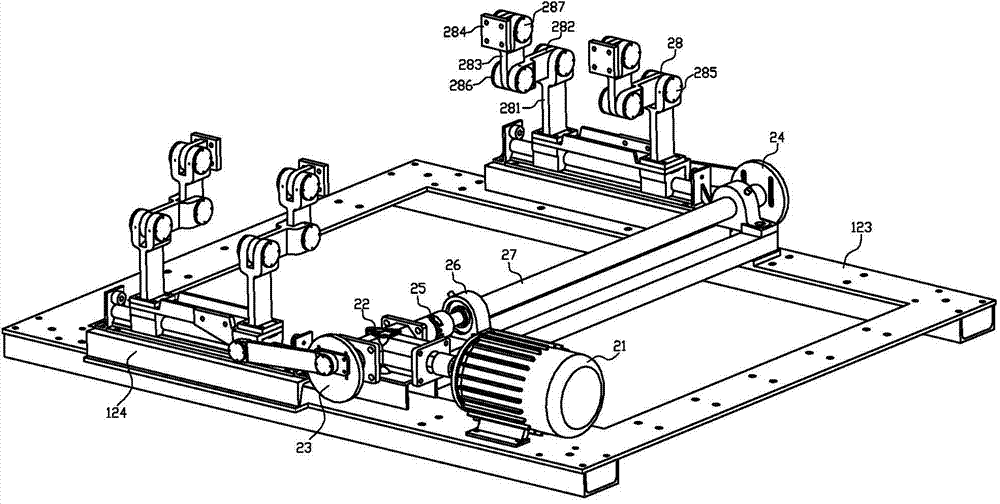

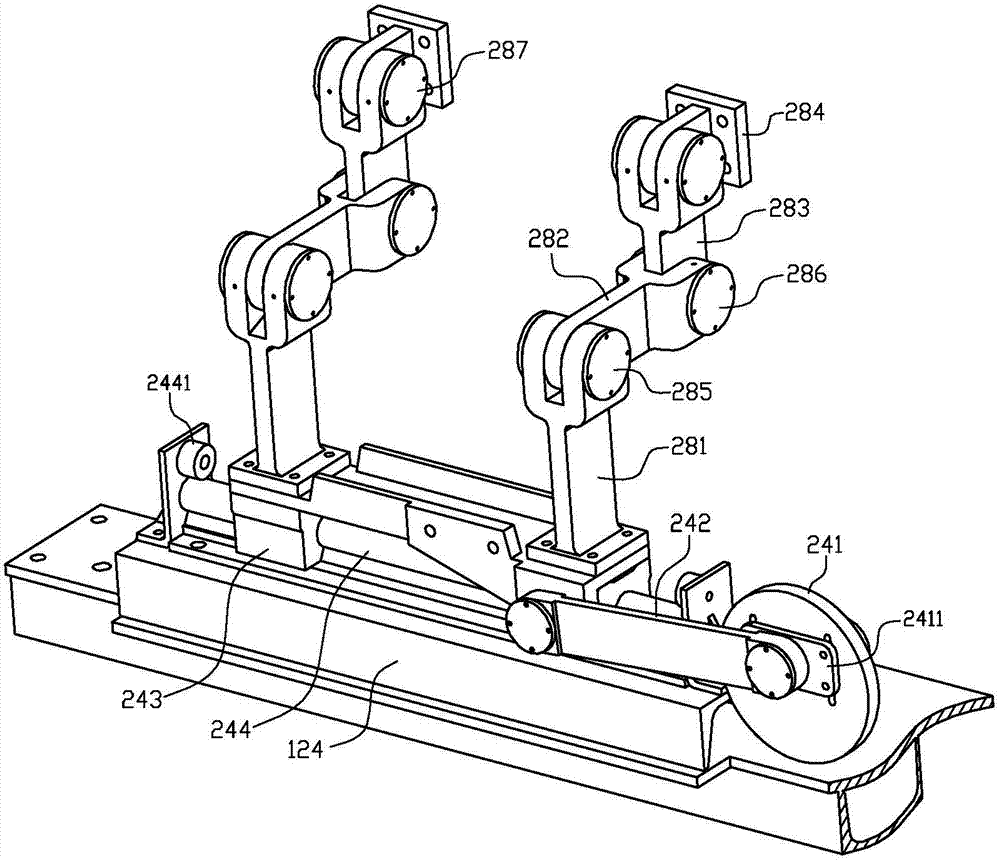

[0028] Such as figure 1 , figure 2 with image 3 As shown, a two-translation-rotation three-degree-of-freedom hybrid vibrating screen includes a support frame 1, a transverse vibration excitation device 2, a screen body 3, a rotary vibration excitation device 4, a vertical vibration excitation device 5, and an auxiliary limit chain 6 , spring 7, eyebolt 8 and hopper 9. Wherein, the support frame 1 includes a bottom bracket 11 and a top bracket 12, and the top bracket 12 is located above the bottom bracket 11 and is fixedly connected with the bottom bracket 11 by screws. On the three sides of the bottom bracket 11, there are material box racks 111 for supporting the material box under the screen, a main beam 121 and an au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com