Series bi-axial baffle automatic adjusting coal powder sorting device with returned powder grinding function

A sorting device and automatic adjustment technology, which are used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of easy jamming of baffles, easy accumulation of powder, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

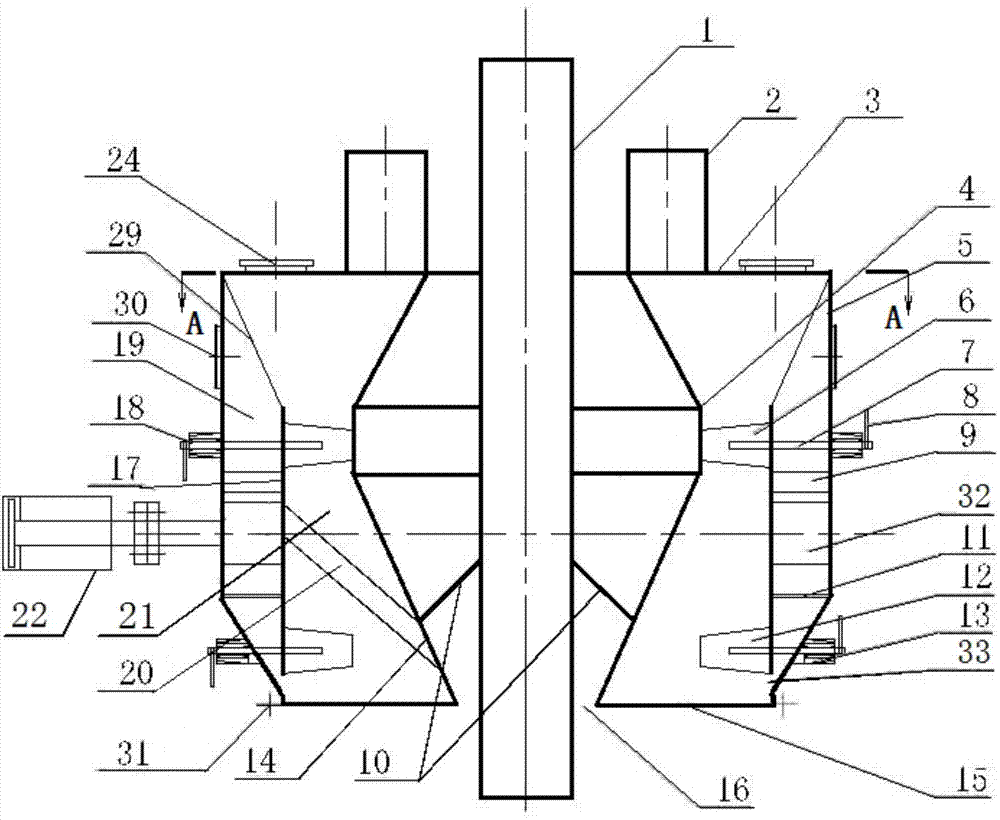

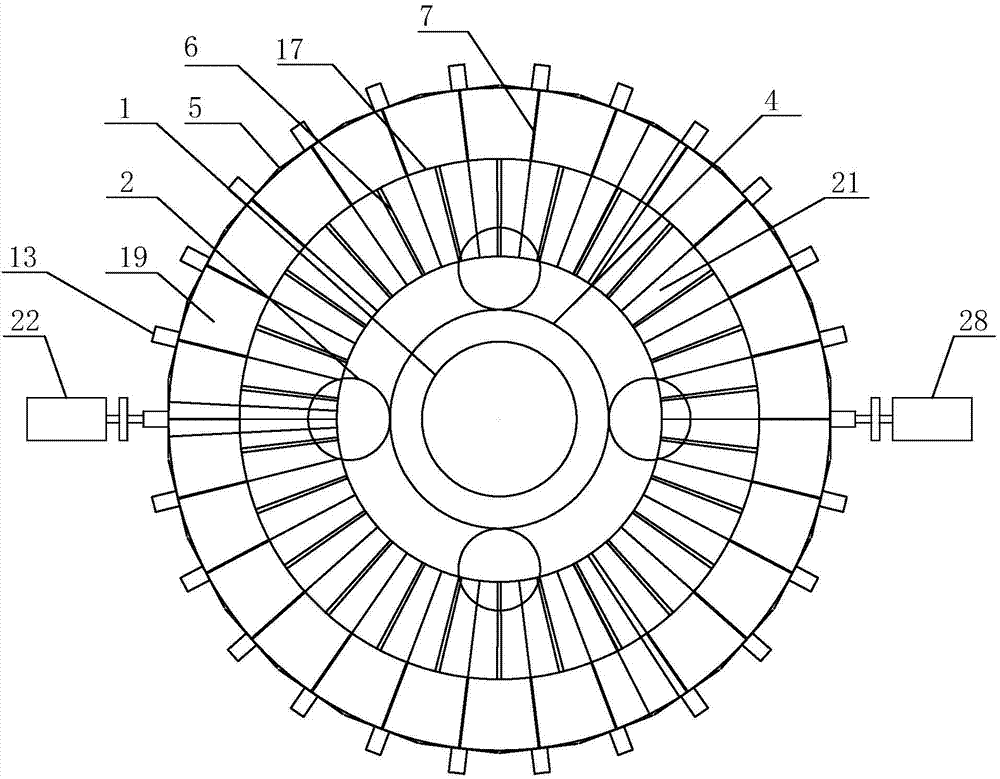

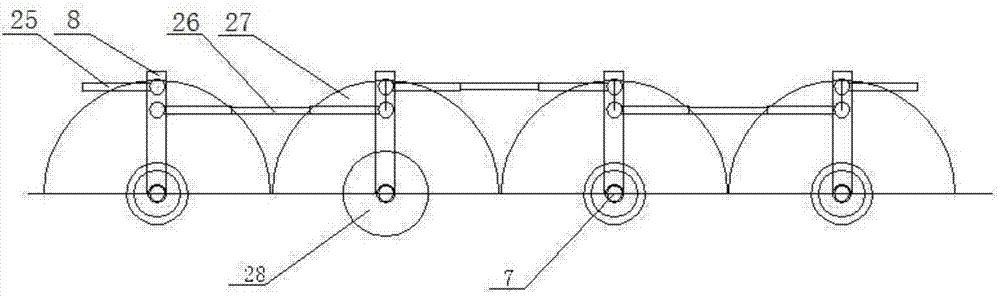

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 As shown, the self-adjusting pulverized coal separation device with serial biaxial baffles for grinding with returned powder includes: coal falling pipe 1, the center of which is passed through by the coal falling pipe Inner cone 4, and outermost shell 5, the upper end face of described sorting device is provided with the cover plate 3 that the center is passed through by described coal drop pipe, and described cover plate or shell top external fixing device There is a primary air duct 2, and a sorting channel 21 connecting the primary air duct from bottom to top is formed between the shell and the inner cone, and the lower part of the inner cone is provided with a conical cap 10 connected to the coal drop pipe; The air-powder mixture from the coal mill spirals up along the sorting channel 21, and the rotation intensity of the air-powder mixture is autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com