Process for producing polymer modified asphalt waterproof coil

A technology of modified asphalt and waterproofing membrane, applied in building construction, building insulation materials, building components, etc., can solve problems such as difficult operation and complicated process route, and achieve short residence time, good plasticizing effect, and blending. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

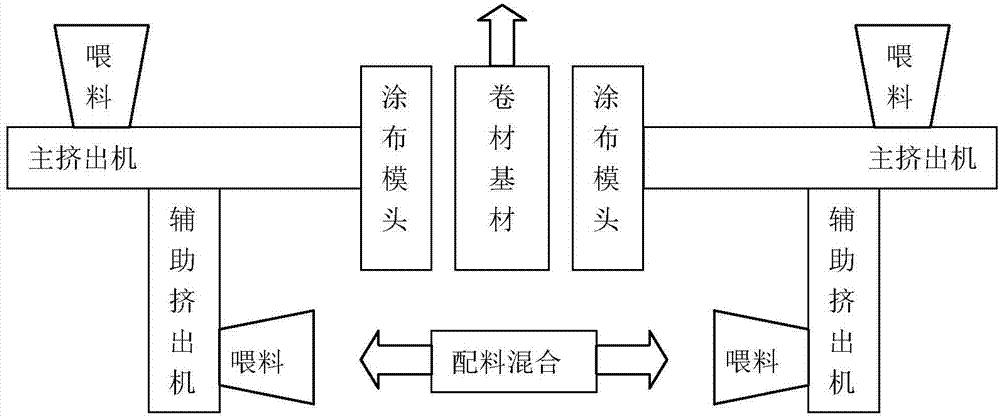

[0036] Such as figure 1 As shown, the production process of the polymer-modified asphalt waterproofing membrane in this embodiment produces a hot-melt double-sided polymer-modified asphalt waterproofing membrane, including the following steps:

[0037] Step 1: Mix the polymer modifier (select SBS) and anti-aging agent (select antioxidant 1010 / UV531) according to the ratio in Table 1, mix evenly, add the feeding device of the main extruder, the temperature of the feeding section of the main extruder As shown in table 2, feeding section (1-4 zone), main extruder is parallel twin-screw extruder;

[0038]Step 2: Freeze and crush the asphalt, add a plasticizer (select the third-line engine oil) and mix with the asphalt, and gradually add fillers (select talcum powder) after mixing evenly; stir and mix again; add the mixture to the feeding device of the auxiliary extruder to assist The temperature range of the extruder is 60-185°C, and the auxiliary extruder is a single-screw extru...

Embodiment 2

[0048] Such as figure 1 As shown, the production process of the polymer-modified asphalt waterproofing membrane in this embodiment produces a self-adhesive single-sided polymer-modified asphalt waterproofing membrane, including the following steps:

[0049] Step 1: Mix the polymer modifier (select SBS and SIS) and anti-aging agent (select antioxidant 1010 / UV531) according to the ratio in Table 3, and add them to the feeding device of the main extruder. Section temperature is as shown in table 4, feeding section (1-4 zone), and main extruder is parallel twin-screw extruder;

[0050] Step 2: Freeze and crush the asphalt (No. 70), add plasticizer (naphthenic oil) and mix with asphalt, after mixing evenly, gradually add filler (talcum powder) and stir again, add interface reactant (polyacrylate), plasticizer Stir the viscous resin (rosin and terpene resin) evenly again; add the mixture to the feeding device of the auxiliary extruder, the temperature range of the auxiliary extrude...

Embodiment 3

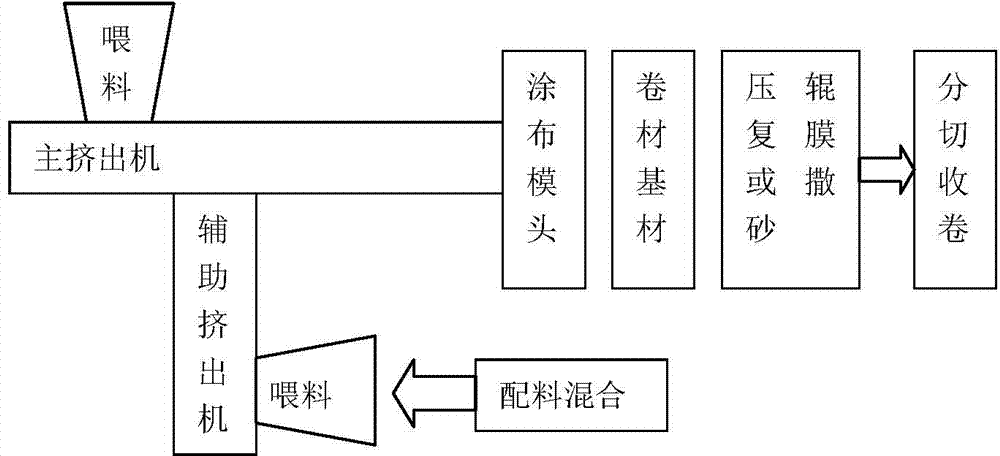

[0060] Such as figure 2 As shown, the production process of the polymer-modified asphalt waterproofing membrane of this embodiment produces a single-side coated self-adhesive polymer-modified asphalt waterproofing membrane, including the following steps:

[0061] Step 1: Mix the polymer modifier (SBS / SIS / IIR) and anti-aging agent (antioxidant 1010 / UV531) according to the ratio in Table 5, and add them to the feeding device of the main extruder, and the feeding of the main extruder Section temperature is as shown in table 6, feeding section (1-4 zone), main extruder is compound single-screw extruder;

[0062] Step 2: Freeze and crush the asphalt (No. 70), add plasticizer (naphthenic oil) and mix with asphalt, after mixing evenly, gradually add filler (talcum powder) and stir again, add interface reactant (polyacrylate), plasticizer Stir the viscous resin (rosin and terpene resin) evenly again; add the mixture to the feeding device of the auxiliary extruder, the temperature ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com