Boiler base of liner movable type ribbon-like filament treatment boiler

A boiler base and flat wire material technology, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of ammonia and ammonia heating and decomposition of hydrogen, and achieve the effect of stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

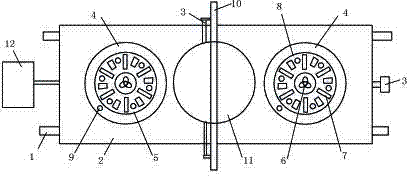

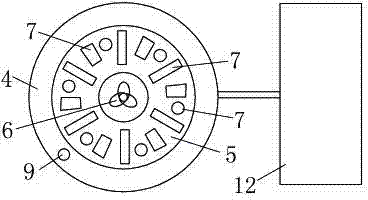

[0011] Combine below figure 1 with figure 2 Specific description embodiment:

[0012] Such as figure 1 with figure 2 As shown, a liner mobile flat wire material processing boiler, the liner mobile flat wire material processing boiler includes a track 1, a sliding frame 2 is provided on the track 1, and the sliding frame 2 passes through the hydraulic device 3 can slide on the track 1, and the sliding frame 2 is provided with a number of boiler bases 4, the middle of the boiler base 4 is the inner tank base 5, the middle of the inner tank base 5 is provided with a fan 6, and the inner tank base 5 is distributed with A number of flat wire material cushions 7, the inner tank base 5 can be sealed with an inner tank 8, the flat wire material base 7 is located inside the inner tank 8, and the boiler base 4 is provided with a drain hole 9; the track 1 A heating jacket 10 is provided at the side, and the heating jacket 10 is connected with a heating jacket 11 through a hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com