Formula of austenite heat-resisting alloy mesh belt wire for continuous mesh belt furnace and preparation method of mesh belt wire

A heat-resistant alloy and austenite technology, which is applied in the formulation of austenitic heat-resistant alloy mesh belt wire for continuous mesh belt furnace and its preparation field, can solve the problem of unsatisfactory comprehensive mechanical properties, short mesh belt wire life, repairing and repairing. Difficulties and other problems, to achieve the effect of reasonable composition design, low component consumption, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The above-mentioned preparation method of austenitic heat-resistant alloy mesh belt wire for continuous mesh belt furnace comprises the following steps:

[0054] A. The raw material preparation is calculated according to the weight percentage of the components contained in the austenitic heat-resistant stainless steel, and the formula is as follows:

[0055] C: 0.01~0.20%; Si: 0.005~3.5%; Mn: 0.01~2.5%;

[0056] P: ≤0.035%; S: ≤0.030%; Cr: 22~27%;

[0057] Ni: 18~26.0%; Co: 0.05~2.5%; Nb: 0.05~1.0%;

[0058] Mo: 0.05~0.2.5%; N: 0.02~0.50%; W: 0.05~1.0%

[0059] Mixed metal rare earth alloy is added, and the rare earth is controlled at 0.003-0.50%; the balance is composed of Fe and unavoidable impurities.

[0060] B. Put the raw materials prepared according to step A into an induction furnace for smelting. During the refining period, the temperature is controlled at 1540°C-1590°C, and the refining time is 25-45 minutes;

[0061] C. Electroslag refining: during the ...

Embodiment 1-3

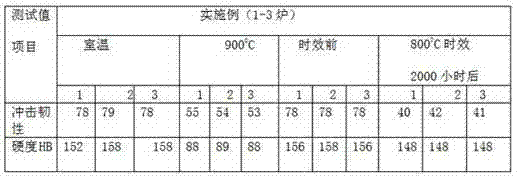

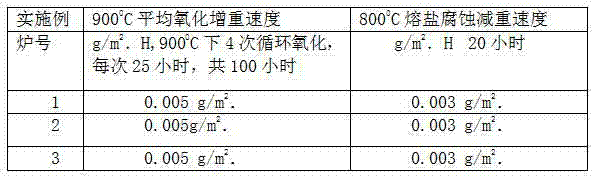

[0092] Embodiment 1-3 furnace, test parameter sees the following table for details:

[0093]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com