Full-automatic mortar conveying machine capable of automatically controlling conveying amount

A fully automatic, high-capacity delivery technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of heavy workload of pumping workers, waste of electric energy and mortar, and high labor intensity of construction workers. The working process is stable and reliable, the replacement is quick and convenient, and the maintenance cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

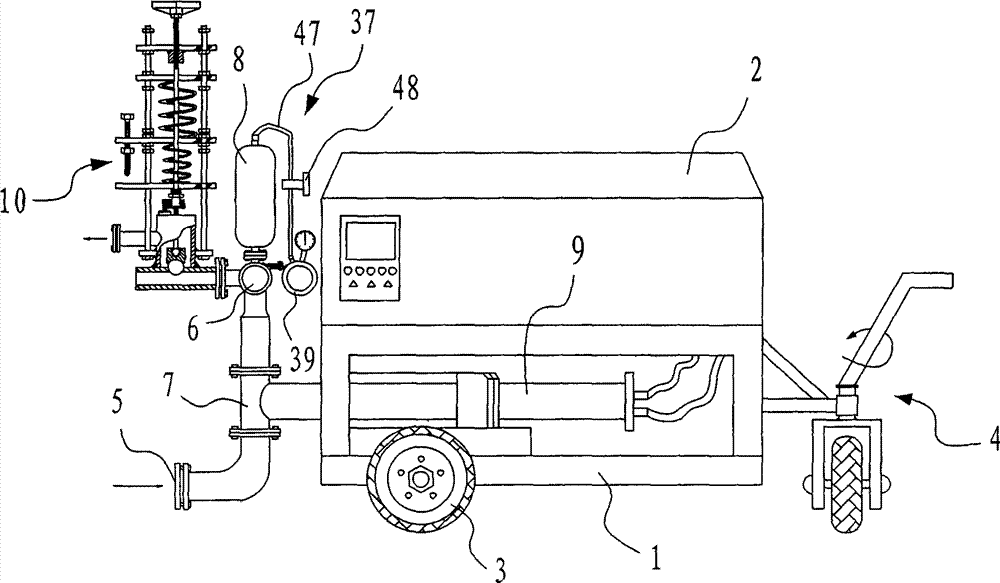

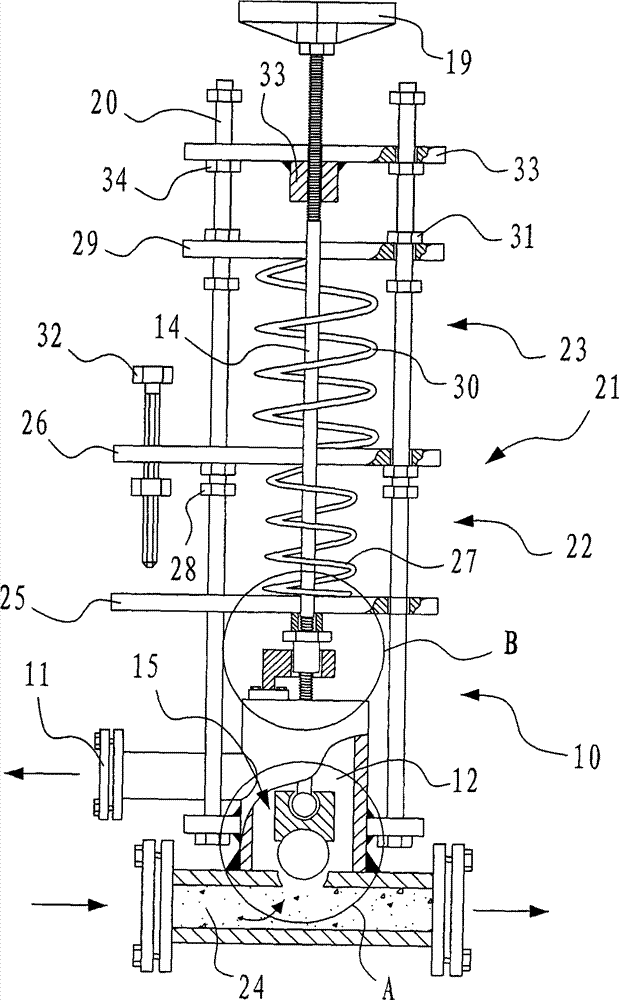

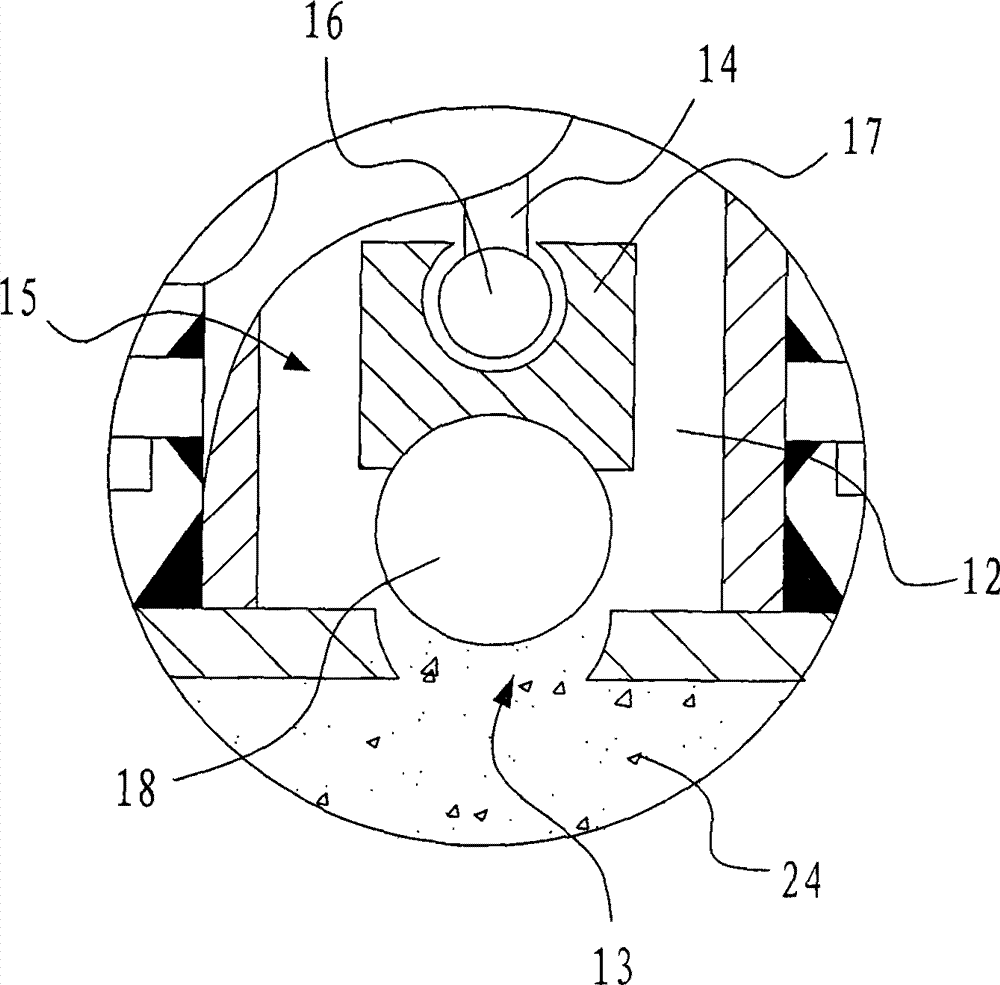

[0026] Such as figure 1 , 2 , 3, 4, 5, and 6, a fully automatic mortar conveyor with automatic control of the delivery volume includes a housing 2 with a base 1, and transport wheels 3 for easy movement are installed on both sides of the base 1, and on the base The end of 1 is equipped with a universal wheel mechanism 4 for easy turning. On the base 1, there are mortar main pipes 7 connected to each other with a mortar suction port 5 and a mortar delivery port 6. Usually, the mortar suction port 5 is connected to a continuous mixer. The turnover box, the mortar delivery port 6 is connected to the mortar collection place of the specific construction site through the pumping equipment pipeline, and the mortar delivery port 6 of the present invention can be directly connected to the spray gun or the mortar spraying machine through the pumping equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com