A TRC-reinforced square column method for improving the bonding of fiber woven mesh and fine concrete

A technology of fine concrete and fiber woven mesh, which is used in building maintenance, solid waste management, sustainable waste treatment, etc., can solve the problems of reduced mesh performance, hard and brittle fiber mesh, and easily broken corners, and achieves simple construction. , the effect of improving adhesion and co-stressing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

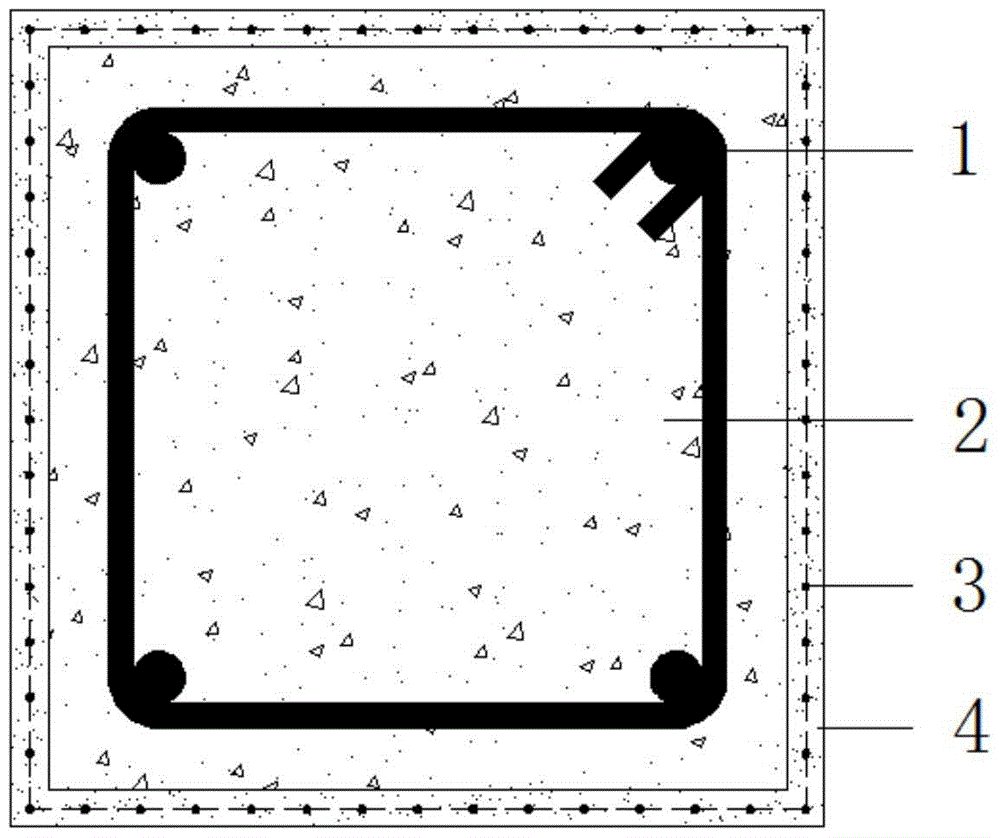

[0039] as attached figure 1As shown, a reinforcement column 2 is reinforced by the method of the present invention, the cross-sectional size of the reinforcement column 2 is 200mm×200mm, and the height of the reinforcement column 2 is 800mm; c =19.1N / mm 2 , the reinforcement column 2 is equipped with 4 HRB400 longitudinal bars 1 with a diameter of 14mm, and the compressive design strength f y =360N / mm 2 , the thickness of the protective layer is 25mm, and the design value of the axial center of the reinforced column 2 is 900kN. Since the column needs to temporarily withstand the force exceeding the design load, under the action of the new load, the axial center pressure of the reinforced column 2 reaches 1600kN. 2 The structure is reinforced.

[0040] The reinforcement of this structure adopts the method of TRC reinforcement, and the fiber woven mesh adopts the weft carbon fiber (f f = 4900Mpa), woven by warp glass fibers, the mesh size of the fiber woven mesh is 10mm × 10...

Embodiment 2

[0049] A method of improving TRC reinforced columns of fiber woven mesh and fine concrete bonding, comprising the steps of:

[0050] 1) The surface of the member 2 to be reinforced is processed into uneven shapes, and chamfering is performed, and the chamfer is 30mm; the bonding ability between the surface of the member 2 to be reinforced and the TRC reinforcement layer is increased without edges and corners, and then the grease is removed. , dust and particles;

[0051] 2) Wet the member 2 to be reinforced with water, and spray the mixed fine concrete onto the surface of the member to be reinforced to form a surface layer of fine concrete with a thickness of 2-3 mm;

[0052] 3) After the fiber woven mesh is impregnated with polymer cement mortar, before the polymer cement mortar is solidified, it is laid on the surface of the surface fine concrete to form the first layer of fiber woven mesh 3; the weft and warp directions of the fiber woven mesh 3 are respectively It is carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com