A kind of anti-lateral force system and bearing capacity calculation method of multi-layer and high-rise steel structure

A calculation method and technology for steel structures, applied in building components, building construction, building maintenance, etc., can solve problems such as out-of-plane buckling, reduced structural ductility, and increased economic costs, so as to improve structural bearing capacity, increase bearing capacity, improve The effect of good seismic energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with embodiment, further illustrate the present invention.

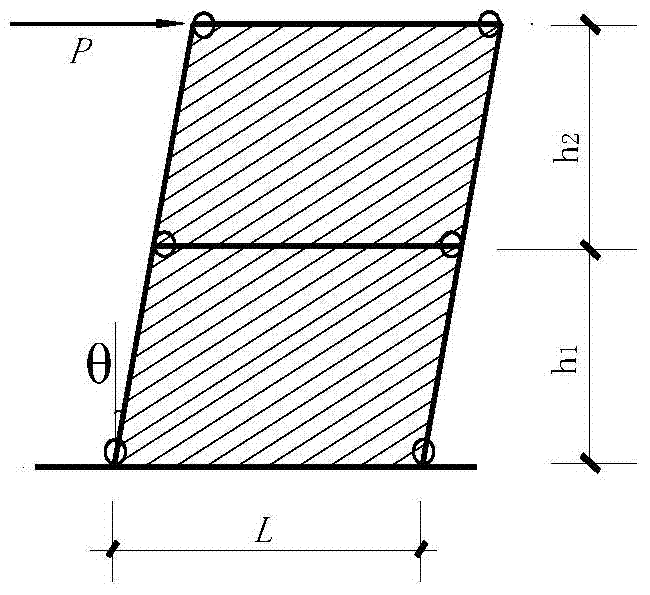

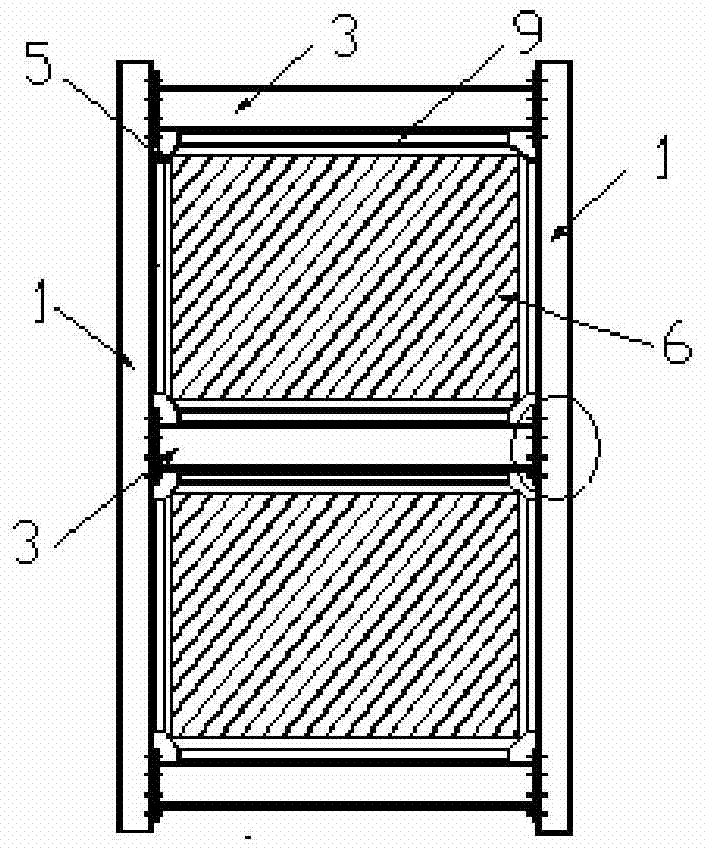

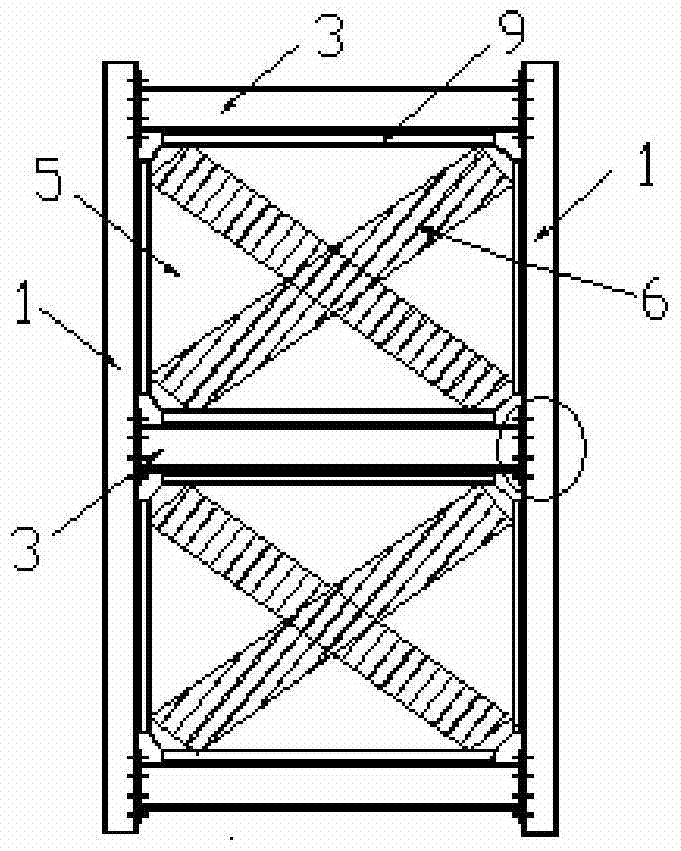

[0036] see Figure 1-Figure 7 , the present invention includes the inner filling steel plate 5, the outer coating carbon-glass hybrid fiber 6 and the steel frame on both sides of the inner filling steel plate. The inner filling steel plate 5 adopts high ductility steel; the carbon-glass hybrid fiber adopts general carbon-glass hybrid fiber, and the laying method includes two methods: the first method is to fully coat the carbon-glass hybrid fiber 6 on both sides of the steel plate, and the second method is The carbon-glass hybrid fiber 6 is laid on both sides of the steel plate in the diagonal direction; the inner filling steel plate 5 is bonded and connected with the carbon-glass hybrid fiber 6 through engineering glue; the steel frame is composed of a frame beam 3 and a frame column 1; The steel frame is composed of frame beams 3 and frame columns 1 , and the frame beams 3 are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com