Air-excess engine

A technology of excessive air and engine, applied in the field of thermal energy and power, can solve the problems of pollution discharge, large volume, complex processing and manufacturing, etc., and achieve the effect of less pollution discharge, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

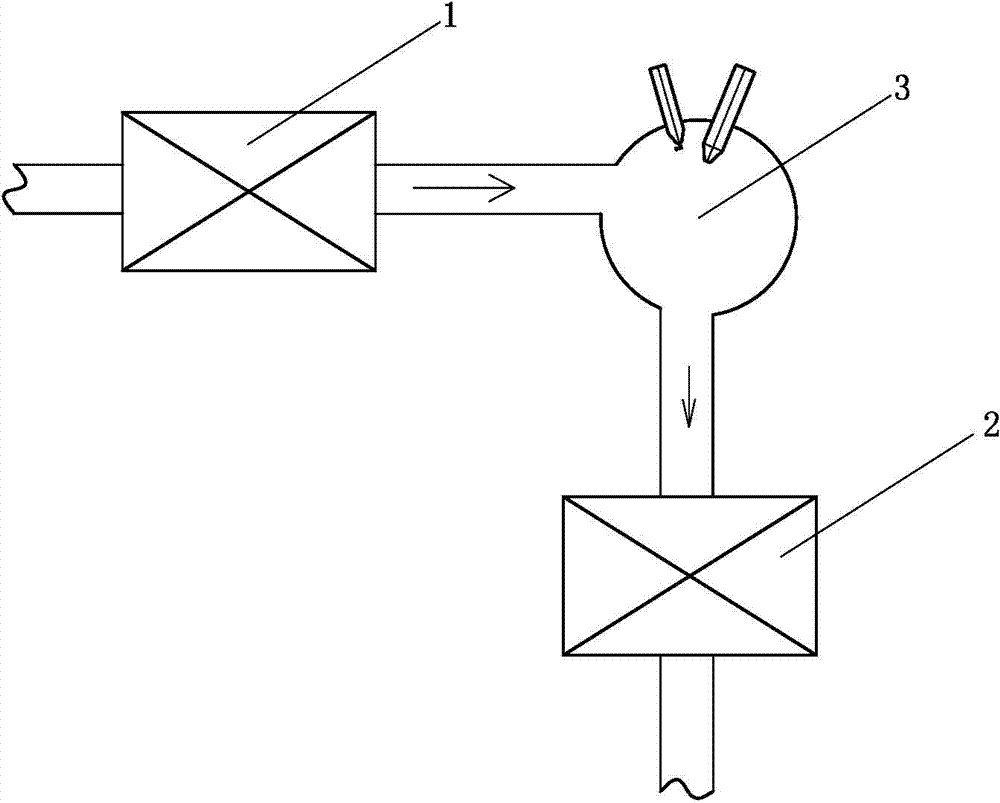

[0044] Such as figure 1 The shown excess air engine includes a volumetric compression unit 1 and an expansion work mechanism 2, the volume compression unit 1 is in non-reheat communication with a continuous combustion chamber 3, and the continuous combustion chamber 3 is in communication with the expansion work mechanism 2 , the pressure bearing capacity of the continuous combustion chamber 3 is greater than 1.5MPa, and the mass flow rate of the compressed air flowing into the continuous combustion chamber 3 is 1.5% of the mass flow rate of the air required for fuel combustion flowing into the continuous combustion chamber 3 more than double.

[0045] As a changeable embodiment, the pressure bearing capacity of the continuous combustion chamber 3 can also optionally be set to be greater than 2.0MPa, 2.5MPa, 3MPa, 3.5MPa, 4MPa, 4.5MPa, 5MPa, 5.5MPa, 6MPa, 6.5MPa, 7MPa, 7.5MPa, 8MPa, 8.5MPa, 9MPa, 9.5MPa or greater than 10MPa.

[0046] As a changeable embodiment, the mass flow...

Embodiment 2

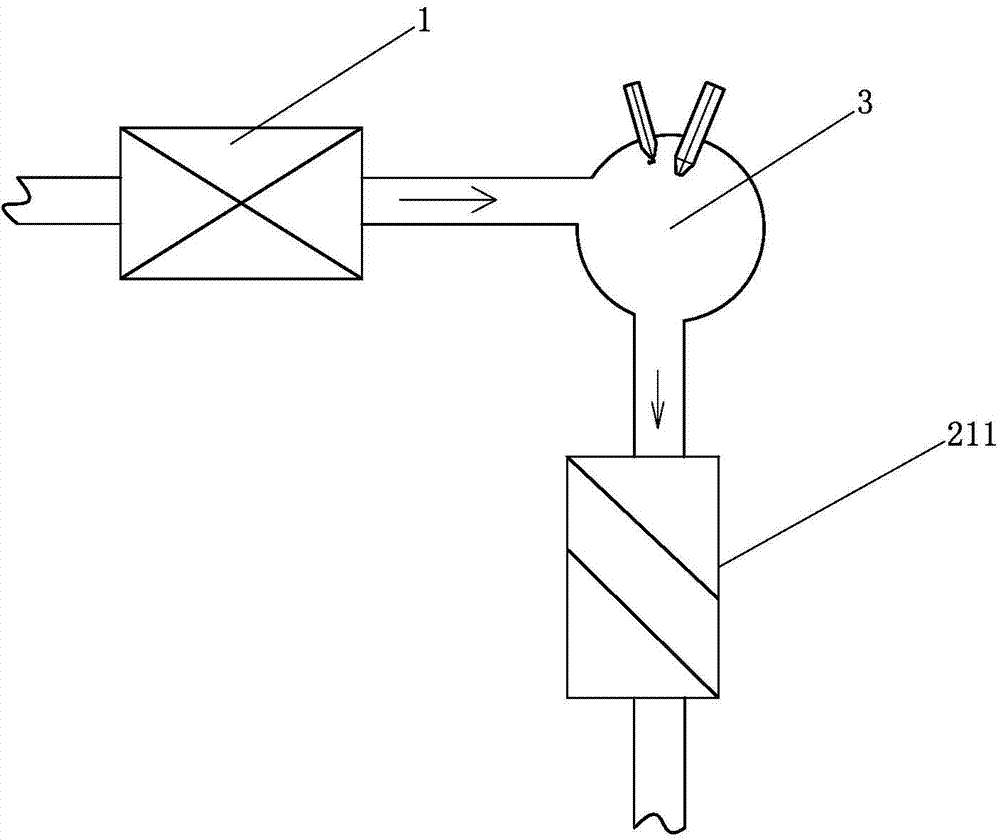

[0048] Such as figure 2 The difference between the excess air engine shown and Embodiment 1 is that the expansion working mechanism 2 is set as a self-expanding volume type fluid mechanism, specifically, the self-expanding volume type fluid mechanism is set as a screw fluid mechanism 211 .

[0049] As an alternative embodiment, the self-expanding volume fluid mechanism can also be changed to a scroll fluid mechanism.

Embodiment 3

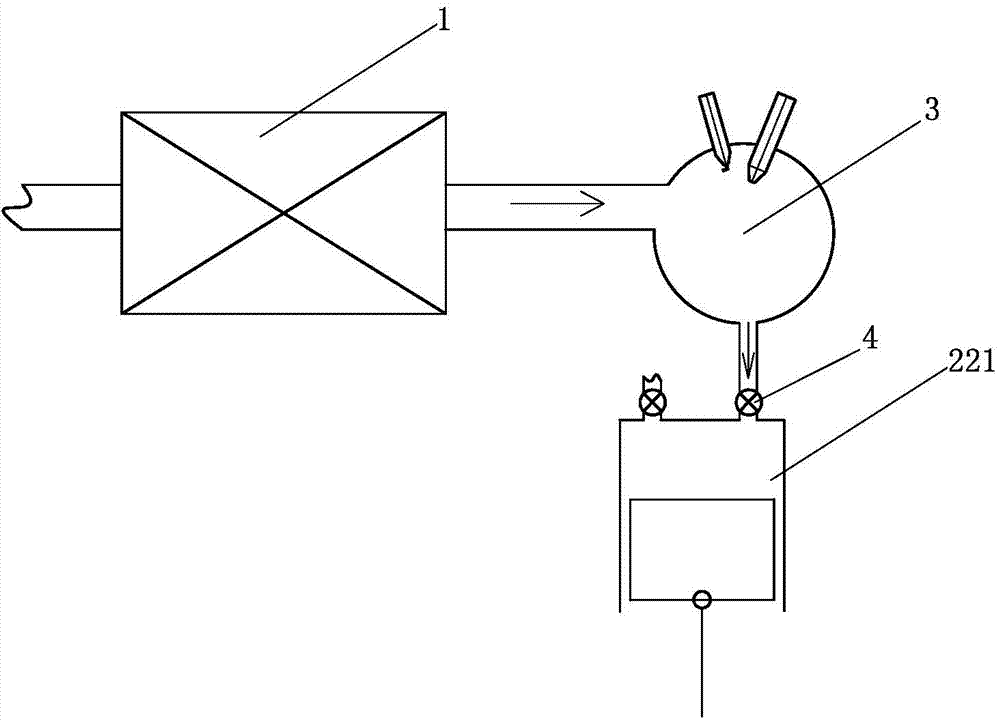

[0051] Such as image 3The difference between the excess air engine shown and Embodiment 2 is that the expansion working mechanism 2 is changed to a non-self-expanding volume type fluid mechanism with a control valve 4 at the inlet, specifically, the non-self-expanding volume Type fluid mechanism is set as reciprocating cylinder-piston mechanism 221.

[0052] As an alternative embodiment, the non-self-expanding volumetric fluid mechanism can optionally be changed to a rolling fluid mechanism, a slide fluid mechanism, a rotary piston mechanism, a swing cylinder-piston mechanism or a liquid piston mechanism.

[0053] As an alternative embodiment, the non-self-expanding volumetric fluid mechanism can optionally be changed to a non-self-expanding volumetric fluid mechanism including a Wankel mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com