Impeller type counter-flow drier

An impeller type, dryer technology, applied in the direction of drying solid materials, drying gas layout, drying, etc., can solve the problems of inconvenient operation and maintenance, low drying efficiency, large plant area, etc., and achieve excellent drying and cooling effect of materials , The effect of low later use and maintenance costs, and simple equipment operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

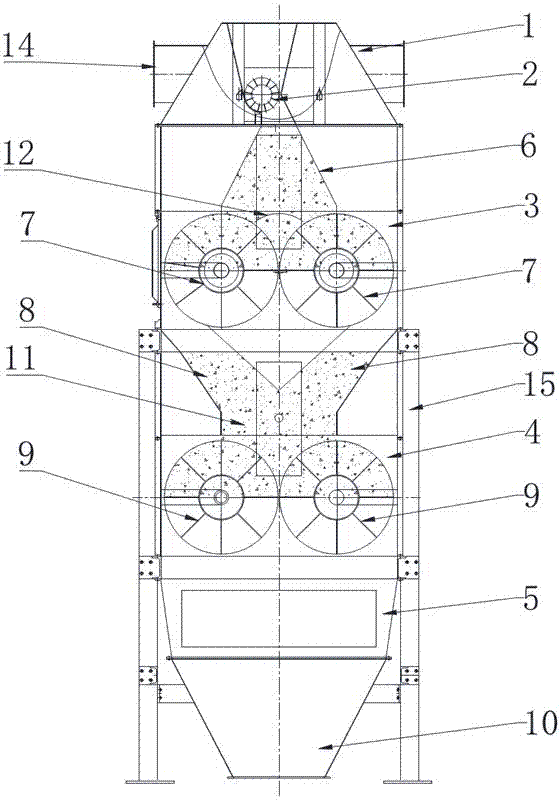

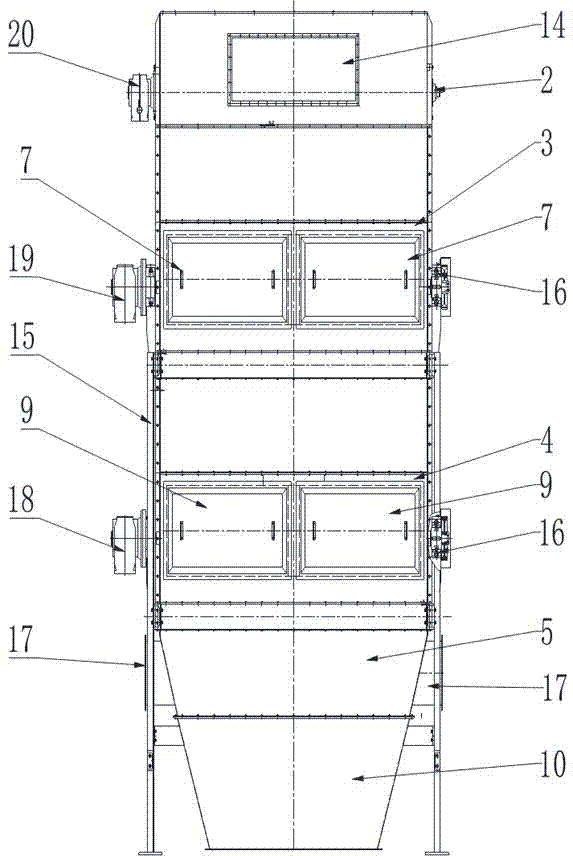

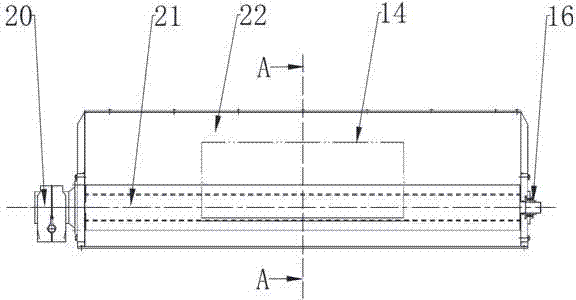

[0045] The impeller type countercurrent dryer includes a frame 14. The frame 14 is sequentially provided with a suction system 1, a Guanfeng feeding system 2, a first dynamic cooling and drying chamber 3, a second dynamic cooling and drying chamber 4 and hot air from top to bottom. Storehouse 5; the side of frame 14 is provided with an airtight shell; hot air storehouse 5 blows hot air for drying and cooling into the shell, and the hot air passes through the second dynamic cooling and drying storehouse 4, the first dynamic cooling and drying storehouse from bottom to top The bin 3 and the dried materials are finally discharged through the suction system 1; the lower part of the hot air bin 5 is provided with a feeder 10 for outputting the dried materials. The material to be dried moves from top to bottom, and is dried and sprinkled by the first dynamic cooling and drying chamber 3 and the second dynamic cooling and drying chamber 4. The hot drying air passes through the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com