Low-power-consumption high-precision electromagnetic heat meter and mounting and use method thereof

A high-precision, electromagnetic technology, applied in the application of electromagnetic flowmeters to detect fluid flow, volume/mass flow generated by electromagnetic effects, and measuring devices, etc., can solve the problem of affecting measurement accuracy, poor anti-dirt ability, and inaccurate flow measurement and other problems, to achieve the effect of improving measurement accuracy, high magnetic field density, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment relates to the field of flow metering equipment, and in particular provides a low power consumption and high precision electromagnetic heat meter.

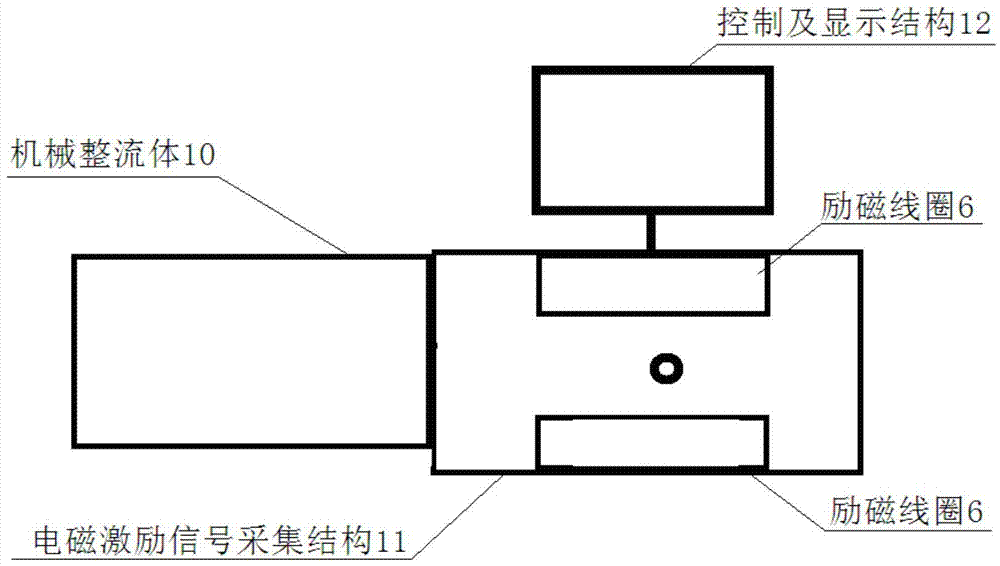

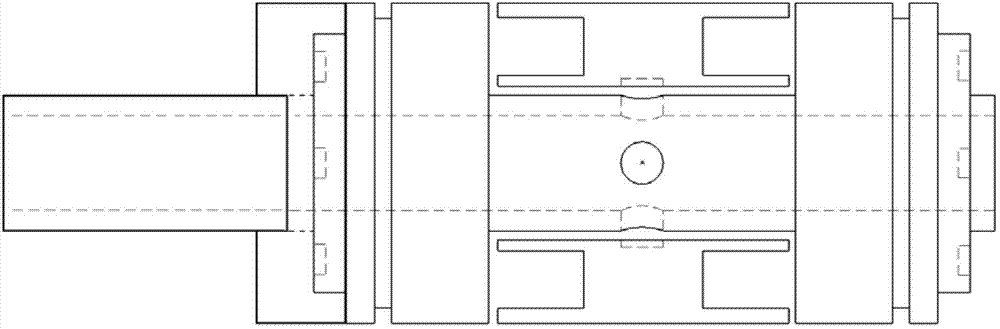

[0045]This embodiment specifically provides a low-power high-precision electromagnetic heat meter including a mechanical rectifier 10, an electromagnetic excitation signal acquisition structure 11, a control and display structure 12, and the electromagnetic excitation signal acquisition structure 11 is fixed on the mechanical rectifier through a flange. 10 front end, the control and display structure 12 is placed outside the mechanical rectifier 10 and the electromagnetic excitation signal acquisition structure 11, and the control and display structure 12 is electrically connected to the electromagnetic excitation signal acquisition structure 11; specifically,

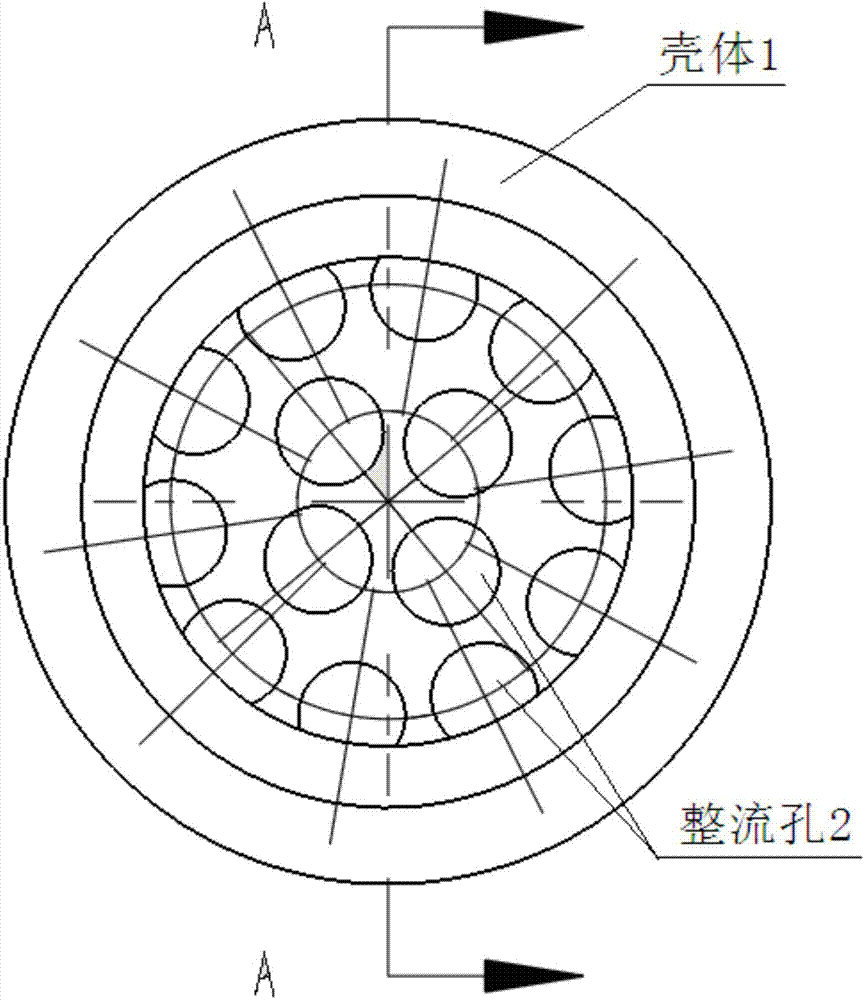

[0046] The mechanical rectifier 10 includes a casing 1, a rectification hole 2, and a zoom tube 3. The rectification hole 2 is arranged in front of t...

Embodiment 2

[0071] This embodiment is a low-power consumption high-precision electromagnetic heat meter, which is applied to household heating water metering. Connect the low power consumption and high precision electromagnetic heat meter described in this embodiment to the household heating pipeline through joints, and set it behind the entrance valve.

Embodiment 3

[0073] This embodiment is a large-diameter high-precision electromagnetic heat meter, which is used for pipeline measurement in the petrochemical industry. Connect the high-precision electromagnetic heat meter described in this embodiment to petroleum and chemical pipelines through flanges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com