Pelletized blast furnace slag hydraulicity detection method

A technology for granulating blast furnace slag and a detection method, which is applied in the detection field to achieve the effects of shortening time, speeding up performance and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

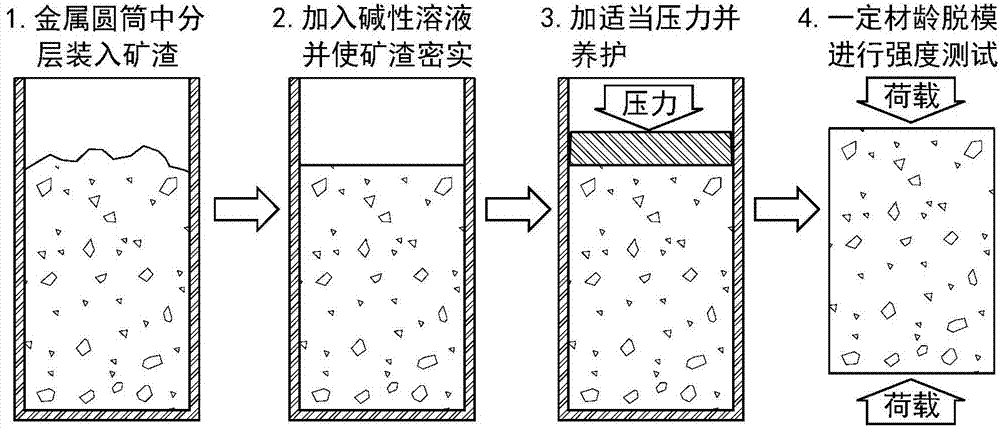

[0018] A method for detecting hydraulicity of granulated blast furnace slag, comprising the steps of:

[0019] The first step: put the granulated blast furnace slag sample to be tested: the sample diameter is 70 mm, and the height is 93 mm, and put it into the container;

[0020] The second step: add calcium hydroxide solution with a pH value of 12, and immerse the granulated blast furnace slag to be tested in the alkaline solution, mix the alkaline solution and the slag evenly by fully stirring, and make the granulated blast furnace slag to be tested dense slag;

[0021] Step 3: Apply a certain constant pressure on the top of the granulated blast furnace slag to be tested for 72 hours, that is, apply a constant pressure of 3kg (converted pressure is 7kPa) on the top of the sample by means of heavy loading, in order to speed up the hydraulicity of the granulated blast furnace slag. , the sample is placed in an environment with a temperature of 80°C for curing, and the curing ...

Embodiment 2

[0023] Embodiment 2: a kind of granulated blast furnace slag hydraulicity detection method, it comprises the following steps:

[0024] Step 1: Put the sample of granulated blast furnace slag to be tested: 70 mm in diameter and 101 mm in height, into a container;

[0025] The second step: adding a sodium hydroxide alkaline solution with a pH value of 11, and immersing the granulated blast furnace slag to be tested in the alkaline solution, mixing the alkaline solution and the slag evenly by fully stirring, and Make the slag to be tested dense;

[0026] Step 3: Apply a certain constant pressure on the top of the granulated blast furnace slag to be tested for 48 hours, that is, apply a constant pressure of 5kg on the top of the sample by means of heavy loading (converted pressure is 13kPa). In order to speed up the hydraulicity of the granulated blast furnace slag, the sample was placed in an environment with a temperature of 60°C for curing, and the curing time was 48 hours;

...

Embodiment 3

[0028] Embodiment 3: a kind of granulated blast furnace slag hydraulicity detection method, it comprises the following steps:

[0029] The first step: put the granulated blast furnace slag sample to be tested: the sample diameter is 70 mm, and the height is 96 mm, and put it into the container;

[0030] The second step: adding the calcium hydroxide alkaline solution with a pH value of 12, immersing the granulated blast furnace slag to be tested in the alkaline solution, mixing the alkaline solution and the slag evenly by fully stirring, and Make the slag to be tested dense;

[0031] Step 3: Apply a certain constant pressure on the top of the granulated blast furnace slag to be tested for 168 hours, that is, apply a constant pressure of 5kg on the top of the sample by means of heavy loading (converted pressure is 13kPa). In order to speed up the hydraulicity of the granulated blast furnace slag, the sample was placed in an environment with a temperature of 40°C for curing, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com