A high overload distribution transformer

A distribution transformer and high overload technology, applied in the field of transformers, can solve the problems affecting the heat dissipation effect of the heat sink on the box, the performance of the distribution transformer, and the poor air circulation of the box, so as to achieve strong anti-sudden short-circuit capability, The effect of low reactive power loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

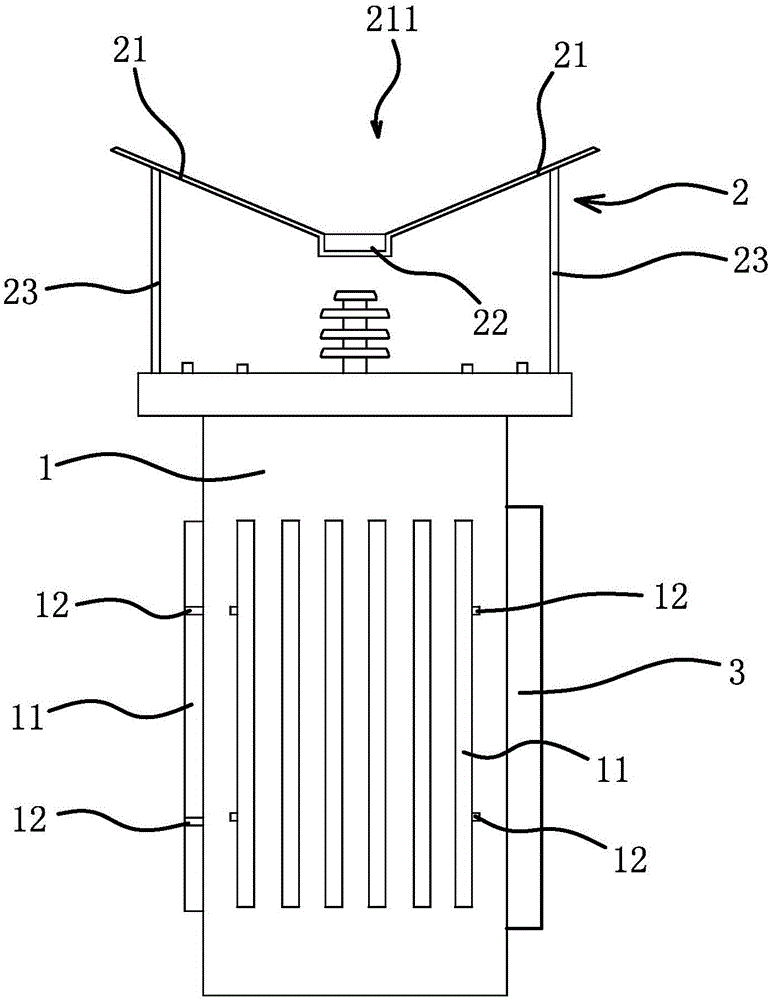

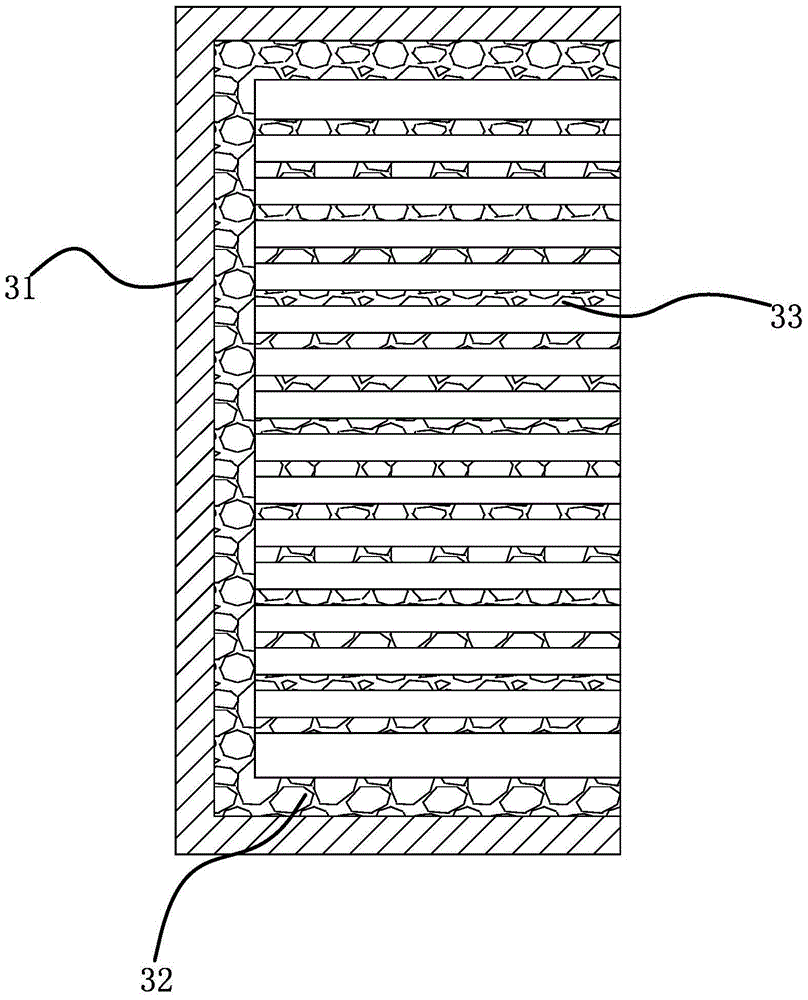

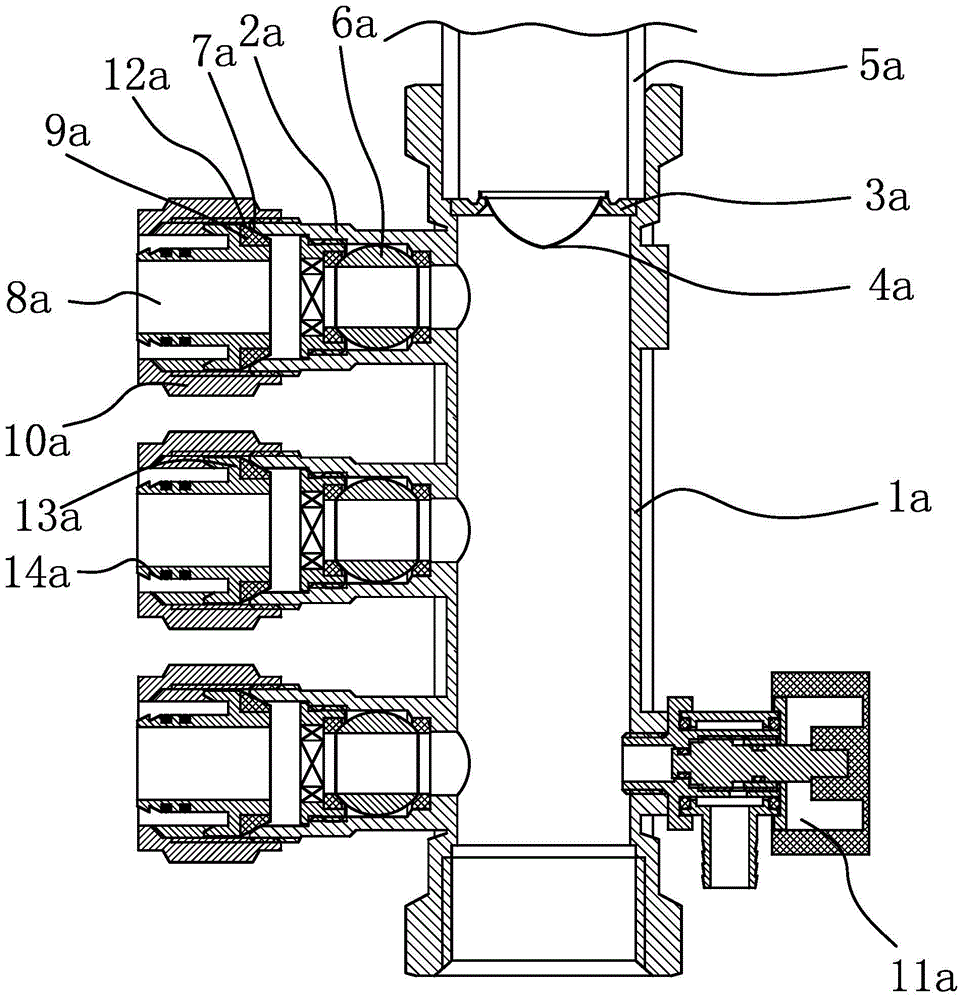

[0027] This example figure 1 with figure 2 As shown, the high overload distribution transformer includes a casing 1, an iron core set in the casing 1 and an oil tank connected to the casing 1. The iron core adopts a three-phase four-frame and five-column structure, including four independent iron core frames Composed side by side, the iron core frame is rounded and rectangular, the iron core frame is made of amorphous alloy material, and each outer surface of the housing 1 is evenly provided with a set of heat sink groups, and each group of heat sink groups is composed of several heat sinks 11 Equally spaced uniform set composition.

[0028] The upper end of the housing 1 is fixed with a rain shelter 2, and the rain she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com