Flexible lining substrate and manufacture method, display substrate and display device

A flexible substrate and display substrate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of shortened component life, component damage, poor absorption and release, etc., to achieve good absorption The effect of heat and the ability to dissipate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

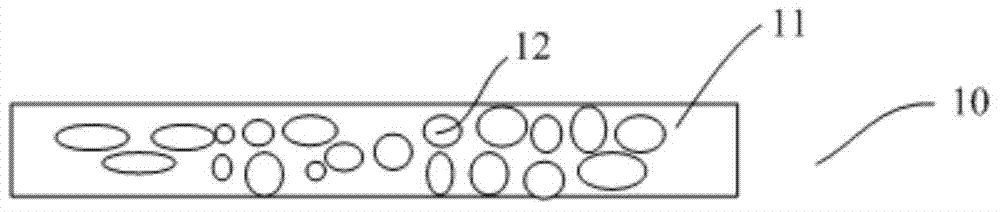

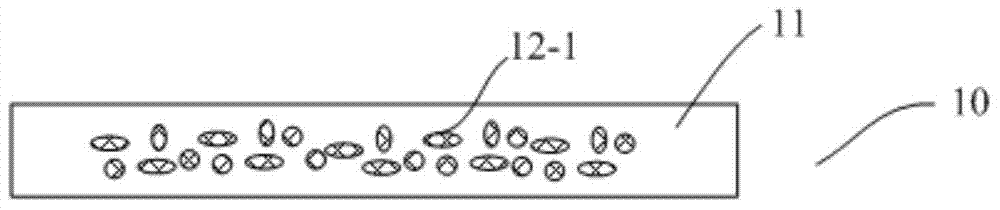

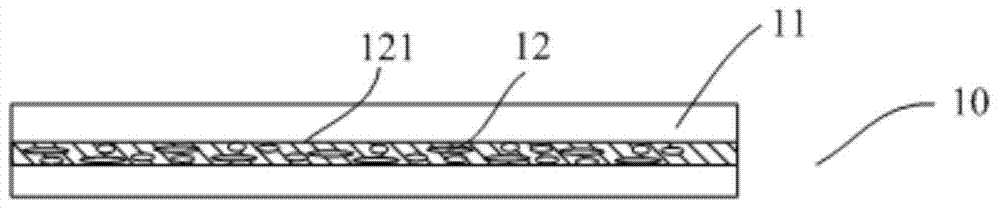

[0026] Such as figure 1 As shown, this embodiment provides a flexible substrate 10 , including a flexible substrate 11 and a phase change material 12 disposed in the flexible substrate 11 .

[0027] Those skilled in the art can understand that the phase change material 12 refers to a substance that changes physical properties and provides latent heat as temperature changes. The process of changing physical properties is called a phase change process, and at this time the phase change material 12 will absorb or release a large amount of latent heat. Taking the solid-liquid phase change as an example, when heated to the melting temperature, a phase change from solid to liquid occurs. During the melting process, the phase change material 12 absorbs and stores a large amount of latent heat; when the phase change material 12 cools, The stored heat must be dissipated to the environment within a certain temperature range, and undergo a reverse phase transition from liquid to solid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com