Environment-friendly composite functional flexible fireproof cable

A composite function, fireproof cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems that affect the promotion and application of fireproof cables, unstable electrical performance, expensive manufacturing equipment, etc., to improve the stability of electric resistance and working temperature, excellent corrosion resistance and radiation resistance, good heat absorption and water blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

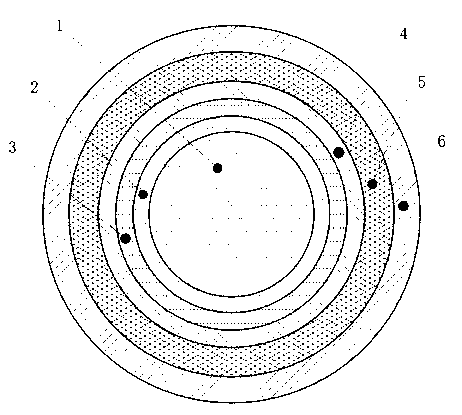

[0038] Embodiment one: see figure 1 , an environment-friendly composite functional flexible fireproof single-core cable, which sequentially includes a conductor core 1, a fireproof layer 2, an insulating layer 3, a waterproof layer 4, a fireproof inner sheath 5 and a fireproof outer sheath 6 from inside to outside. Among them, the conductor core 1 is made of a number of soft round copper wires with the same diameter in a regular and concentric layered twist; the refractory layer 2 is processed by synthetic mineral refractory composite tape; the insulating layer 3 is made of 150 ° C It is processed by irradiation cross-linked polyolefin halogen-free insulating material; the waterproof layer 4 is processed by heat-insulating, halogen-free, low-smoke and high-flame retardant material; The outer sheath 6 is made of environmentally friendly, highly flame-retardant, low-smoke, halogen-free polyolefin material.

Embodiment 2

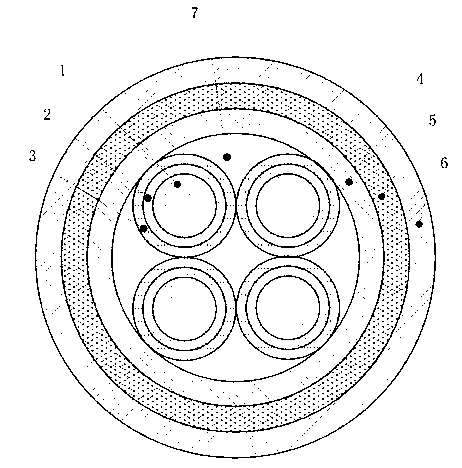

[0039] Embodiment two: see figure 2, an environment-friendly composite function flexible fireproof multi-core cable, which is composed of a cable inner core and an insulating and protective outer layer, the insulating and protective outer layer is wrapped around multiple cable inner cores, and fillers are arranged between the multiple cable inner cores 7. The cable inner core includes conductor core 1, refractory layer 2 and insulating layer 3. There are two or more cable inner cores (4 cable inner cores in the figure), and the outer insulation protection layer includes waterproof layer 4. Fireproof Inner sheath 5 and fireproof outer sheath 6. Among them, the conductor core 1 is made of a number of soft round copper wires with the same diameter in a regular and concentric layered twist; the refractory layer 2 is processed by synthetic mineral refractory composite tape; the insulating layer 3 is made of 150 ° C It is processed by irradiation cross-linked polyolefin halogen-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com