Power distribution cabinet panel

A kind of technology of power distribution cabinet and panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

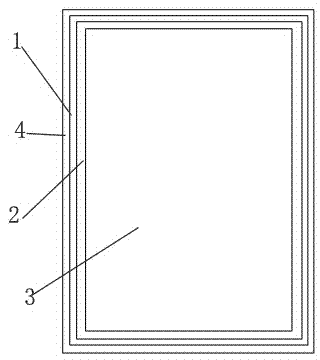

[0011] like figure 1 As shown, a power distribution cabinet panel according to the present invention includes an aluminum-copper alloy substrate 1, the inner side of the aluminum-copper alloy substrate 1 is bonded with a glass fiber layer 2 by engineering glue, and the aluminum-copper alloy substrate 1 is larger than the glass fiber layer 2 The edge width of the aluminum-copper alloy substrate 1 is 3 mm-6 mm; the inner surface of the aluminum-copper alloy substrate 1 is glued with a PE protective film 3 , and the outer surface of the aluminum-copper alloy substrate 1 is glued with a PVC protective film 4 .

[0012] The thickness of the PE protective film 3 is 1-1.5mm; the thickness of the PVC protective film 4 is 2-3mm; the thickness of the aluminum-copper alloy substrate 1 is 4-6cm; the thickness of the glass fiber layer 2 The thickness is 1-3cm.

[0013] There are many specific application approaches of the present invention, and the above description is only a preferred em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com