Laminated paper honeycomb composite material and preparation method thereof

A composite material and paper honeycomb technology, which is applied in the field of preparation of laminated composite paper honeycomb composite materials, can solve the problems of poor waterproofness, difficult to form, easy to deform, etc., and achieves good energy absorption, sound insulation and heat insulation performance, and good corrosion resistance. and safety, good electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

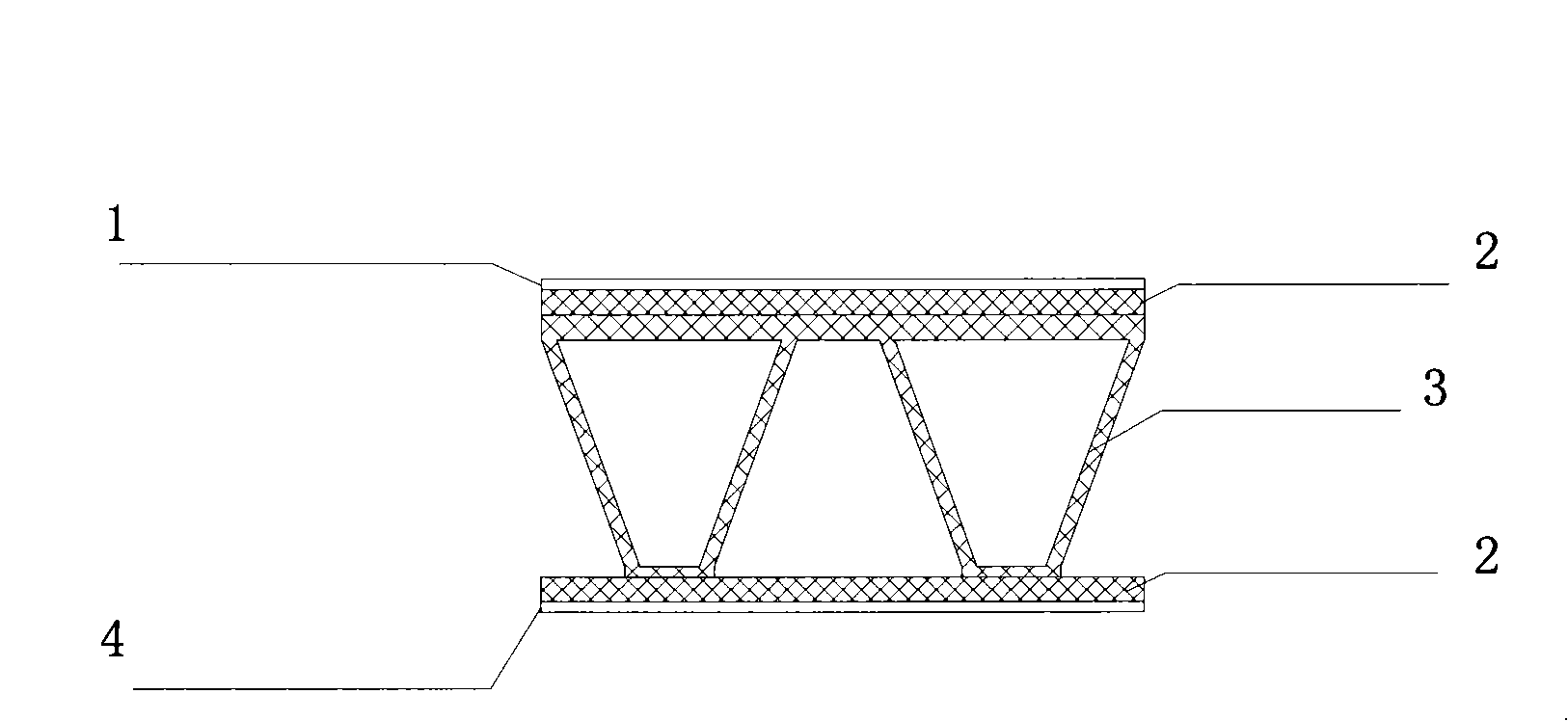

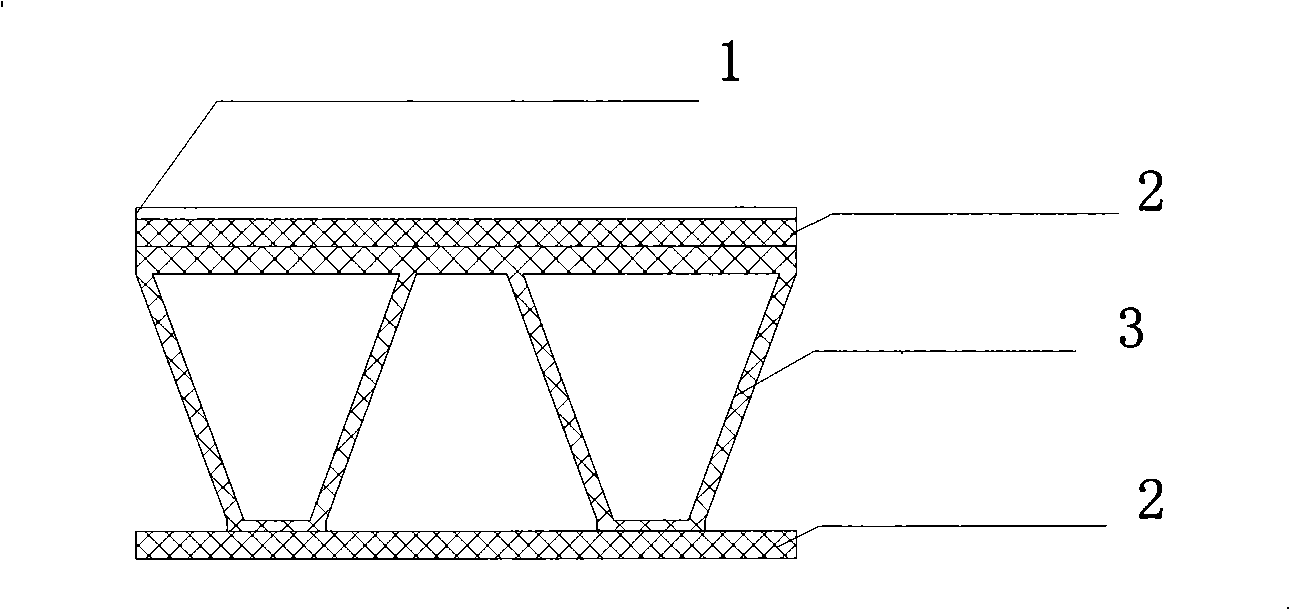

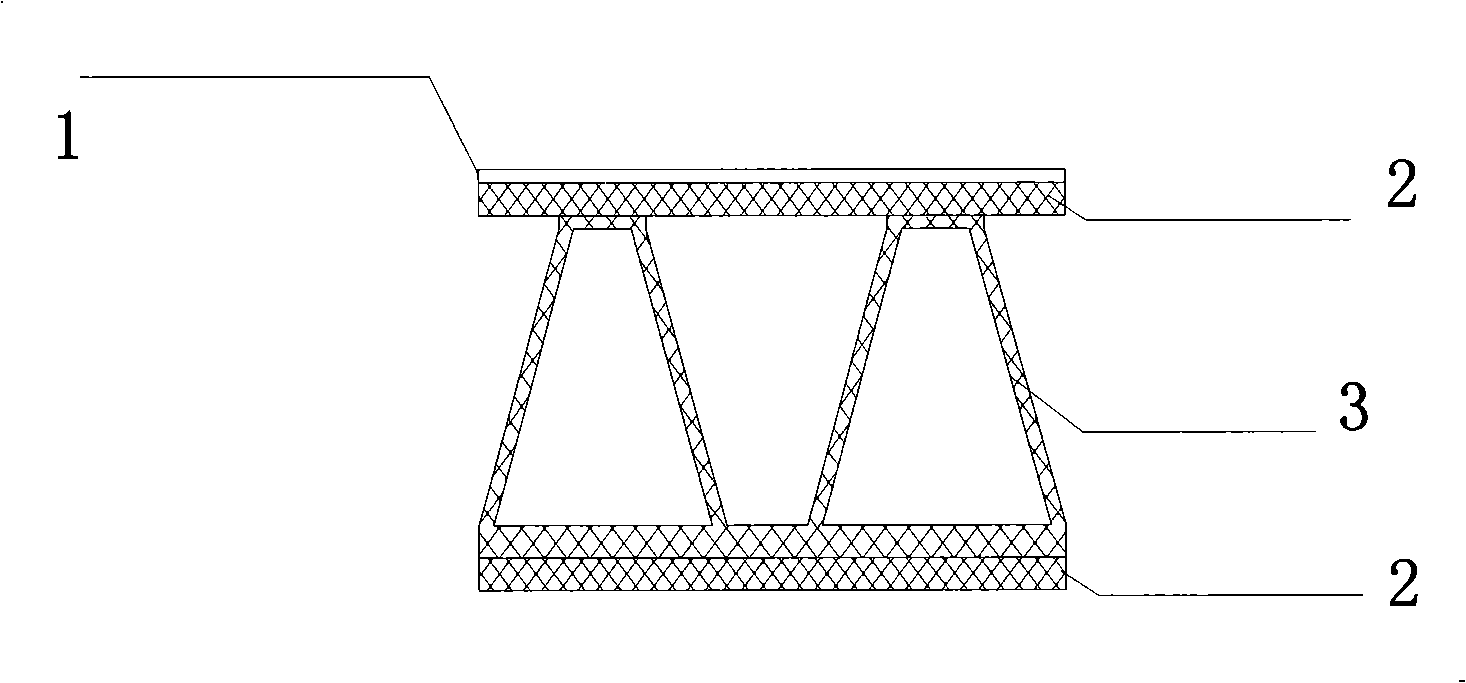

[0024] The laminated paper honeycomb composite material and its preparation method of the present invention will be described below with reference to the drawings and examples.

[0025] The preparation method of laminated paper honeycomb composite material according to the present invention is characterized in that the preparation steps include: preparing honeycomb paperboard, polypropylene plastic particles, carpet, non-woven fabric raw materials - extruding poly Propylene sheet, lamination and compounding, pressing-cutting; wherein, the extrusion temperature is between 200-230°C.

[0026] The specific steps are as follows: First, buy honeycomb paperboard, the thickness of which can be selected between 3 and 30 mm according to needs, and purchase fabrics such as carpets and non-woven fabrics (the weight and thickness of which can be freely selected, and can cover all existing types) and PP plastic particles, according to customer needs.

[0027] Secondly, the production line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com