SiC-POSS-EP heat-conduction hybrid material and preparation method thereof

A technology of hybrid materials and functionalization, which is applied in the field of high thermal conductivity materials for PCB, can solve problems such as difficulty in exerting effect and easy agglomeration of nano-scale silicon carbide, and achieve low thermal expansion coefficient, high thermal conductivity and mechanical properties, and reduce the interface Effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: This embodiment provides a SiC-POSS-EP thermally conductive hybrid material, which is made of the following components by weight:

[0032] Epoxy resin EP: 40-80 parts

[0033] Curing agent: 30-60 parts

[0034] Functionalized POSS: 0.1-10 parts

[0035] Silicon carbide SiC: 1-20 parts.

[0036] The epoxy resin is a mixture of one or more of bisphenol F epoxy resin, bisphenol A epoxy resin, bisphenol S epoxy resin and novolac epoxy resin.

[0037] The curing agent is a mixture of one or more of amines, phenolic resins, and acid anhydride curing agents, and the amines are diphenylmethanediamine.

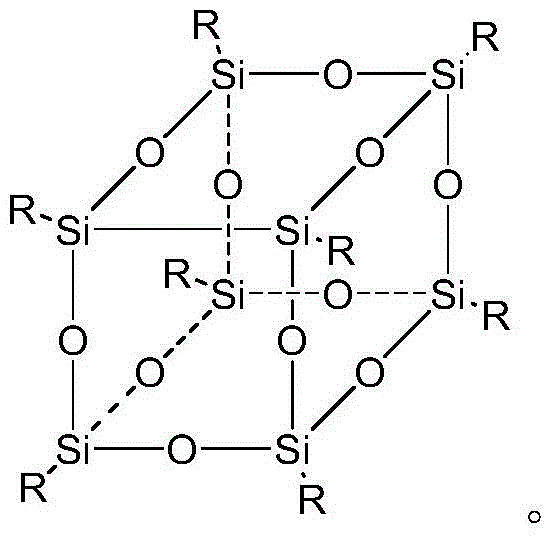

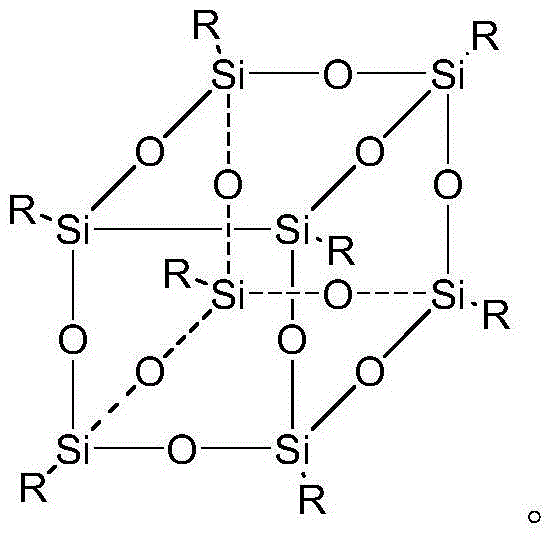

[0038] Described functionalized POSS is cage octapolysilsesquioxane, and its structural formula is:

[0039]

[0040] In the functionalized POSS structural formula, at least one of the R groups is one of epoxy group, carboxyl group, acid anhydride, and amino group, and the remaining R groups are hydrogen atoms, halogen atoms, hydroxyl groups, C1-20 alkyl gro...

Embodiment 2

[0054] Embodiment 2: This embodiment provides a SiC-POSS-EP thermally conductive hybrid material for PCBs, and a method for preparing the SiC-POSS-EP thermally conductive hybrid material. The components and steps are basically the same as in Example 1, and the The difference is:

[0055] A SiC-POSS-EP thermally conductive hybrid material, which is made of the following components in parts by weight:

[0056] Bisphenol S type epoxy resin: 40 parts

[0057] Methyl hexahydrophthalic anhydride: 30 parts

[0058] Cage-shaped octaaminophenylsilsesquioxane: 0.1 parts

[0059] 20nm silicon carbide SiC: 1 part.

[0060] A preparation method according to the SiC-POSS-EP thermally conductive hybrid material, which comprises the following steps:

[0061] (1) prepare each component by following parts by weight:

[0062] Bisphenol S type epoxy resin: 40 parts

[0063] Methyl hexahydrophthalic anhydride: 30 parts

[0064] Cage-shaped octaaminophenylsilsesquioxane: 0.1 parts

[0065] ...

Embodiment 3

[0069] Example 3: This example provides a SiC-POSS-EP thermally conductive hybrid material for PCBs, and a method for preparing the SiC-POSS-EP thermally conductive hybrid material. The components and steps are basically the same as those in Examples 1 and 2. , which differ in that:

[0070] A SiC-POSS-EP thermally conductive hybrid material, which is made of the following components in parts by weight:

[0071] Bisphenol F type epoxy resin: 80 parts

[0072] Diphenylmethanediamine: 60 parts

[0073] Cage octasilsesquioxane: 10 parts

[0074] 100nm silicon carbide SiC: 20 parts.

[0075] A preparation method according to the SiC-POSS-EP thermally conductive hybrid material, which comprises the following steps:

[0076] (1) prepare each component by following parts by weight:

[0077] Bisphenol F type epoxy resin: 80 parts

[0078] Diphenylmethanediamine: 60 parts

[0079] Cage octasilsesquioxane: 10 parts

[0080] 100nm silicon carbide SiC: 20 parts;

[0081] (2) Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com