Magnet vortex energy saving speed controller

A speed governor and magnetic eddy current technology, which is applied in electromechanical transmission devices, electromechanical devices, electrical components, etc., can solve the problems of speed governors with unstable speed, low adjustment accuracy, and inconvenient maintenance, and achieve small torque and extended equipment. The effect of life and avoiding the transmission of mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

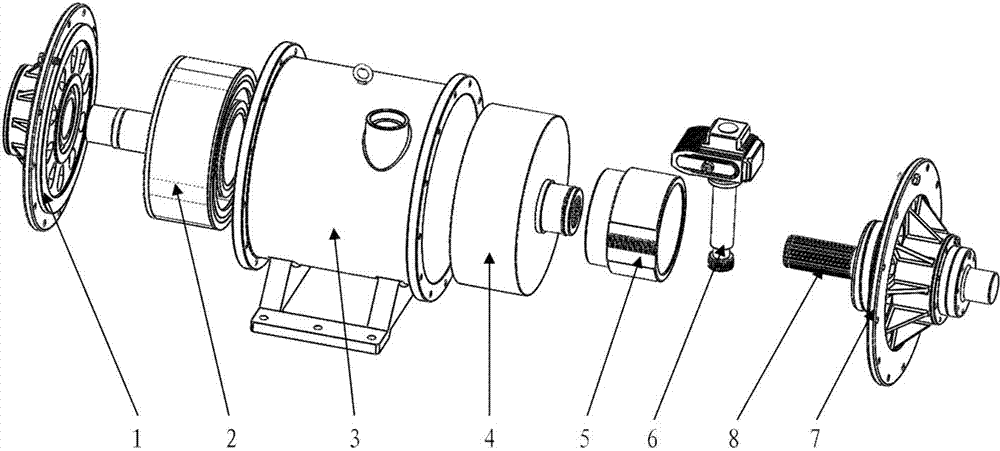

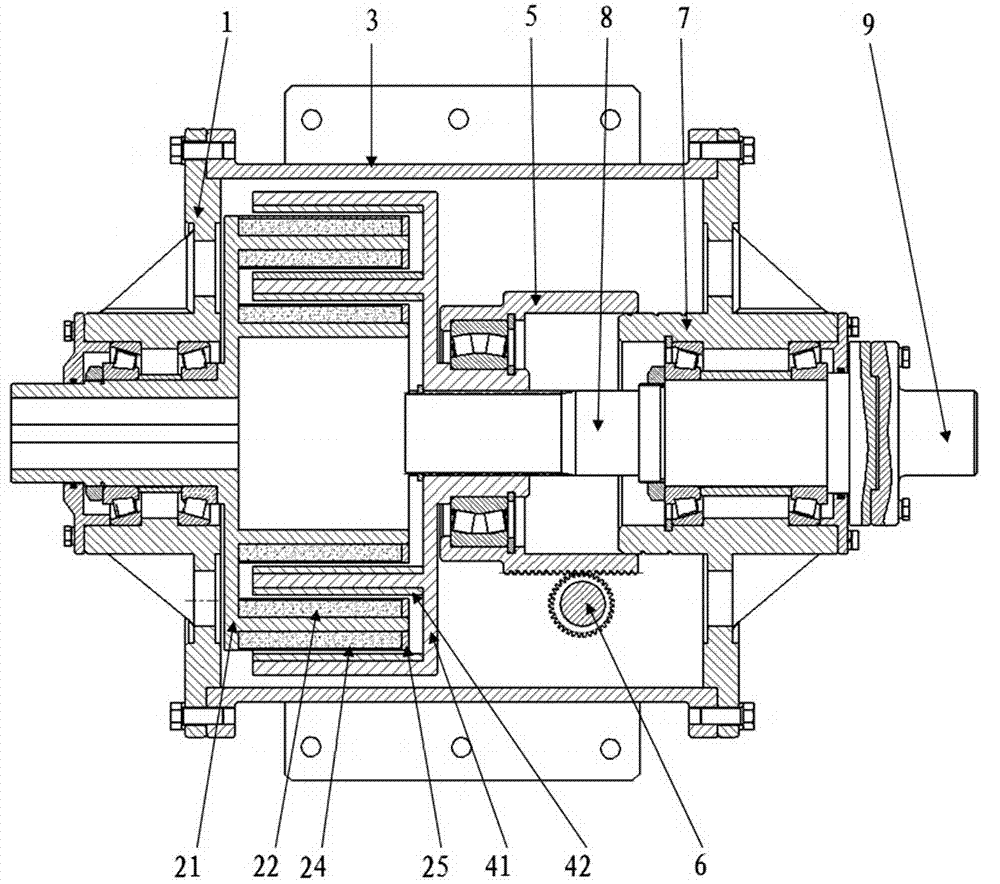

[0053] Magnetic eddy current energy-saving governor, such as figure 1 As shown, it includes a housing assembly 3, a permanent magnet rotor 2 and a conductor rotor 4 that are arranged in the housing assembly 3 and are coupled to each other; the conductor rotor 4 is provided with a sliding part 5 for the axial linear movement of the conductor rotor 4, The sliding part 5 is also connected with a control part 6 for controlling the sliding position of the sliding part 5; the permanent magnet rotor 2 is mounted on the shell assembly 3 through a tapered roller bearing, and the conductor rotor 4 is mounted on the involute spline shaft 8 on the housing assembly 3, and the involute spline shaft 8 is connected to the housing assembly 3 through a tapered roller bearing.

[0054] In the present invention, there is no mechanical connection between the permanent magnet rotor 2 and the conductor rotor 4, one end of the permanent magnet rotor 2 is connected to the motor, one end of the conduc...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that this embodiment optimizes the structure of the permanent magnet rotor 2 and the conductor rotor 4, and the specific settings are as follows:

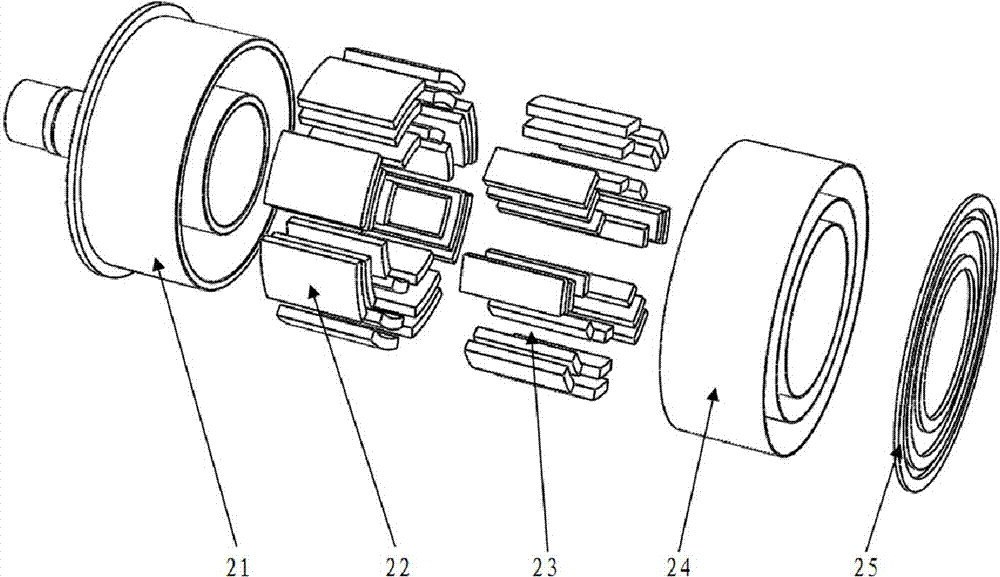

[0060] The permanent magnet rotor 2 includes a permanent magnet rotor base 21 , a magnetic steel mounting ring, a fan-shaped magnetic steel 22 , an envelope 24 , a pressure ring 25 and a spacer 23 .

[0061] In this embodiment, the permanent magnet rotor base body 21 mainly serves as a bearing support for stably fixing the fan-shaped magnetic steel 22 in the housing assembly 3; the magnetic steel mounting ring is fixed on the permanent magnet rotor base body 21, which is mainly It is used to install and fix the sector magnet 22; the main function of the sector magnet 22 is to form an alternating magnetic field and form an eddy current when the conductor is cut; Effect on the magnetic steel mounting ring.

[0062] In the present invention, the number of the magnetic ...

Embodiment 3

[0066] The difference between this embodiment and Embodiment 2 is that in this embodiment, in order to increase the degree of stability, the connection relationship between the permanent magnet rotor 2 and the conductor rotor 4 and the housing assembly 3 is optimized, and the specific settings are as follows:

[0067] The permanent magnet rotor 2 is fixedly connected to the housing assembly 3 through the front end cover 1 , and the sliding part 5 is fixedly connected to the housing assembly 3 through the rear end cover 7 .

[0068] That is, the outer end of the front end cover 1 is fixedly connected with the housing assembly 3 through screws, and the inner end of the front end cover 1 is assembled on the permanent magnet rotor base 21 through tapered roller bearings. The outer end of the rear end cover 7 is fixedly connected with the housing assembly 3 through screws, and the inner end of the rear end cover 7 is assembled and fixed on the involute spline shaft 8 through a taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com