High-stability mini-tiller

A micro-tiller, smooth technology, applied in the field of micro-tiller, can solve the problems of start-up failure, heavy weight, laborious shifting, etc., to reduce labor intensity, ensure successful start-up, and avoid start-up failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

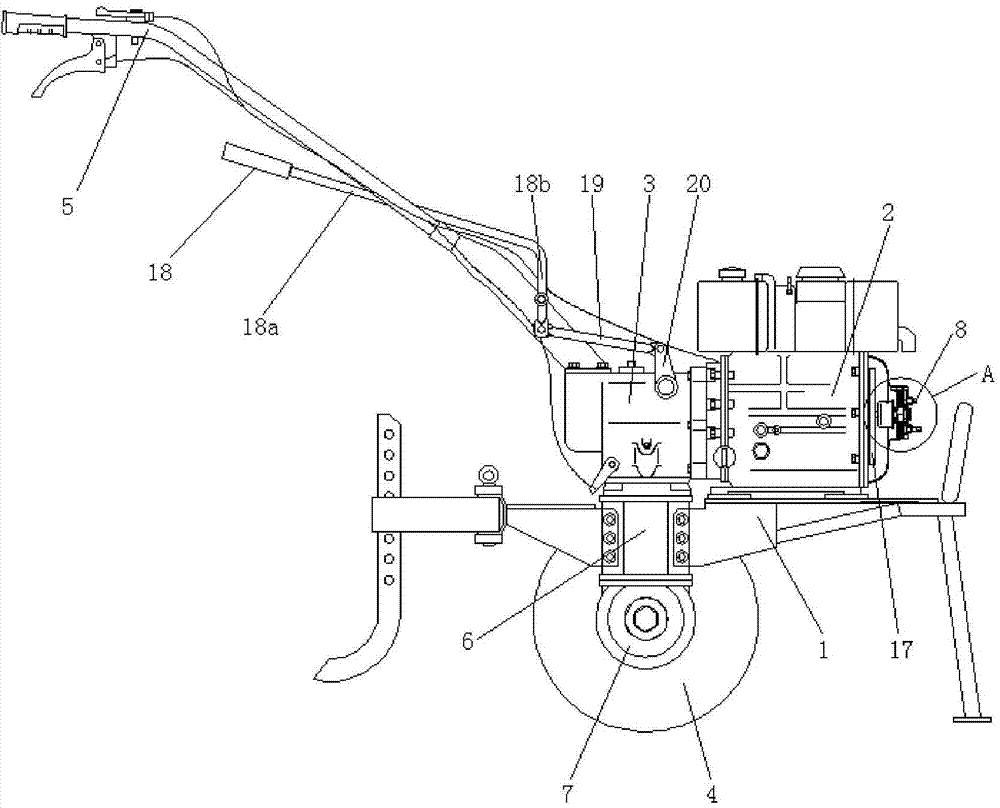

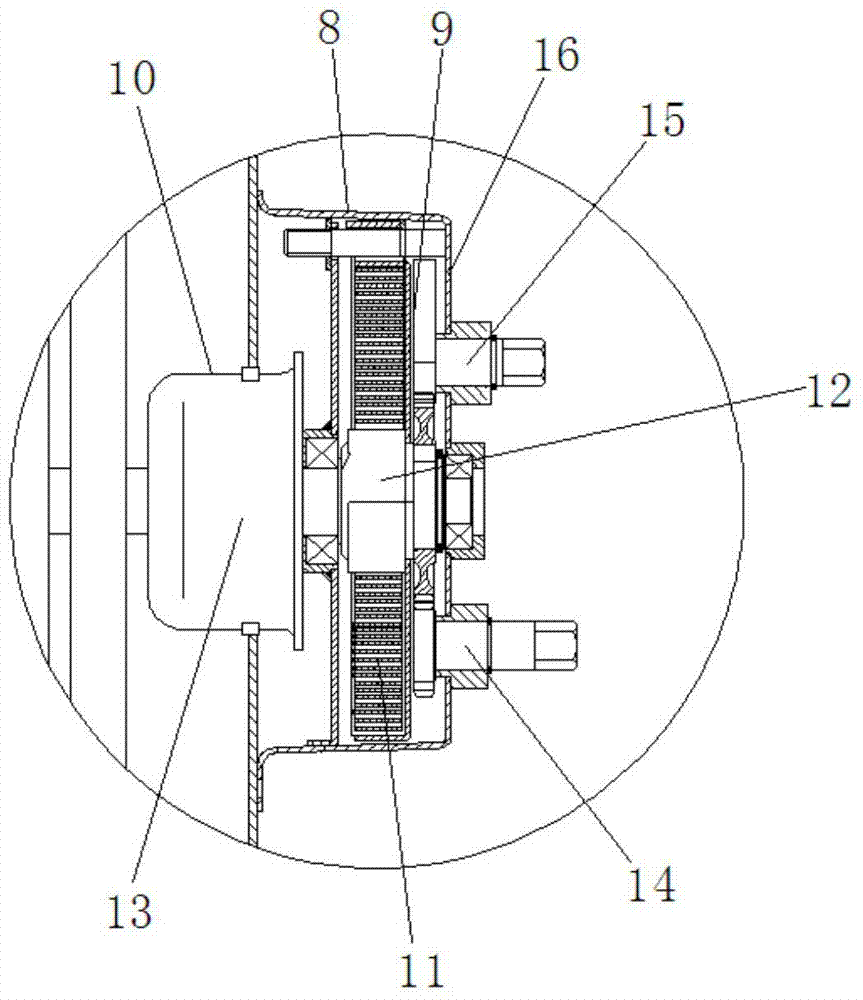

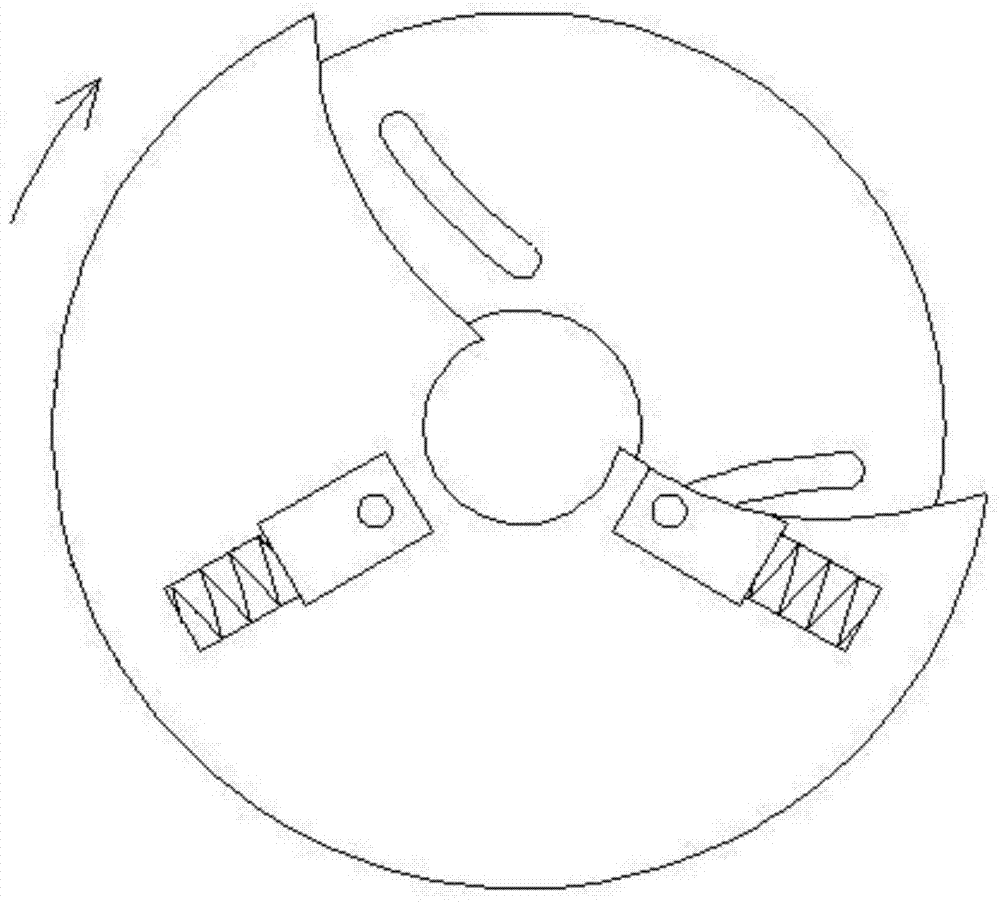

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The zoomed-in view at A, image 3 It is a schematic diagram of the flywheel structure, as shown in the figure: the high stability tillage machine of the present embodiment includes a frame 1, an engine 2, a gearbox 3, a walking wheel 4 and a control handle 5, and the engine 2 and the gearbox 3 are fixed Installed on the frame 1, a transmission box 6 and a travel box 7 are fixedly arranged under the gearbox 3 in sequence, and the wheel shaft of the travel wheel 4 is connected to the travel box 7 in a single degree of freedom rotation and passes through the transmission box 6. The transmission part is connected with the gearbox 3, the control handle 5 is fixedly mounted on the gearbox 3, and the engine 2 is provided with a starter 8 for driving its crankshaft to start; the starter 8 includes an energy storage device 9 and the energy conversion mechanism 10 connected to the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com