Combine harvester self-adaptive cleaning control device and self-adaptive cleaning method thereof

A combine harvester and control device technology, applied to harvesters, applications, agricultural machinery and implements, etc., can solve problems such as frequent blockage failures, unstable machine performance, and inability to meet operational requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

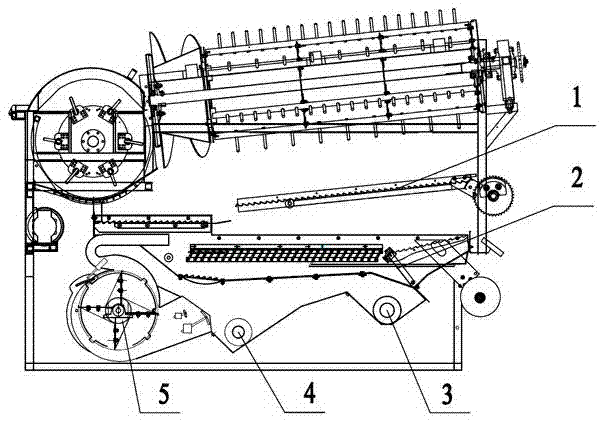

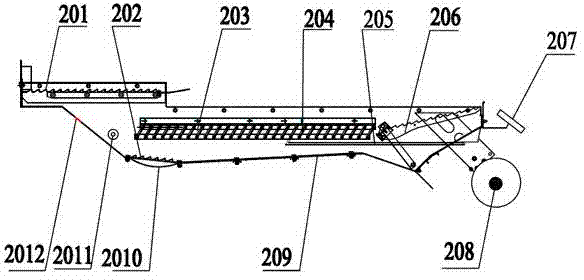

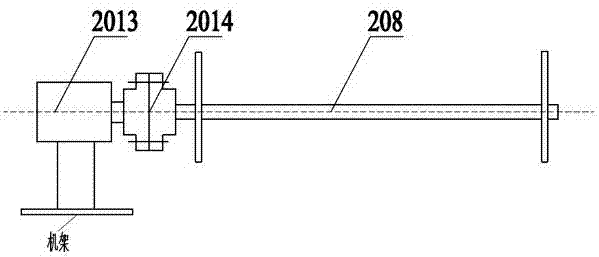

[0043] Such as figure 1 As shown, the multi-air channel self-adaptive cleaning device consists of a return plate 1, a cleaning screen 2, a miscellaneous collection auger 3, a grain collection auger 4, a cleaning centrifugal fan 5, and an automatic monitoring device 6 for the grain content of the grain tank. It is composed of an online monitoring and control system 7 for the operation status of a multi-air duct self-adaptive cleaning device; the return board 1 is located on the upper side of the vibrating screen 2, the residual collection auger 3 is located on the lower side of the tail of the vibrating screen 2, and the grain collection auger 4 is located on the At the 1 / 4 position of the lower side of the vibrating screen 2, the grain collecting auger 4 is flush with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com