Forage fish cutter

A technology of fish cutting machine and bait, which is applied in the direction of cutting fish into parts, feed, food science, etc. It can solve the problems of poor effect, high labor intensity, waste, etc., to avoid waste and pollute water quality, and solve the problems of high labor intensity, The effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Describe in detail the structure and the method of use of the sewage suction device at the bottom of the aquaculture nursery pond of the present invention below:

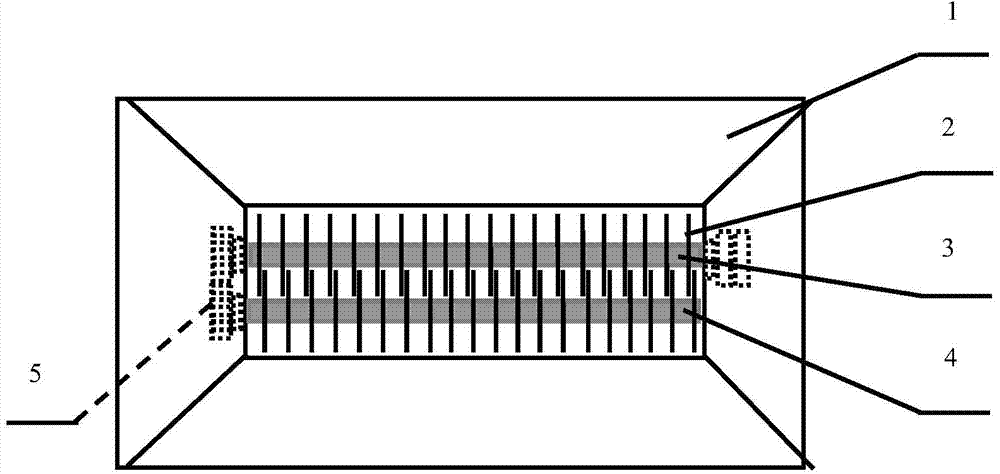

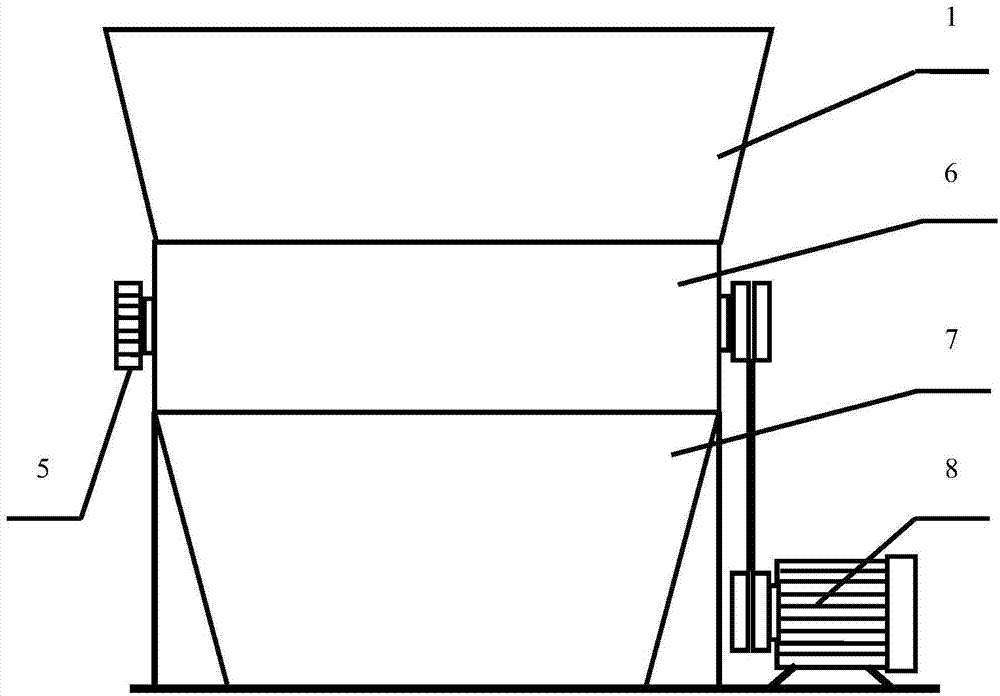

[0010] This device is to intercept two steel rods with a diameter of 3 cm and a length of 60 cm as shafts, on which a cutter head with a diameter of 12 cm is welded, the distance between the cutter heads is 2 cm, and the two shaft cutter heads are staggered and arranged side by side. One of the shafts is driven by a motor and is a driving shaft, and the other shaft is driven by a gear connected to the driving shaft and is a driven shaft.

[0011] The specific operation is as follows: when in use, start the motor first, the driving shaft and the driven shaft rotate in the opposite direction, then put the bait fish into the feeding hopper, the cutter heads on the two shafts form a downward cutting force, and the bait fish Bring into the cutting bin and cut into 2cm fish segments, and finally discharge from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com