A method for reducing transverse cracks in niobium-containing steel corners

A transverse crack, niobium steel technology, applied in the field of continuous steel casting in the metallurgical industry, can solve the problems of difficulty in eliminating transverse cracks at the corners, low niobium content, affecting the quality of niobium-containing steel, etc. Effects of transverse cracks on corners of niobium-containing steel and enhanced solidification uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

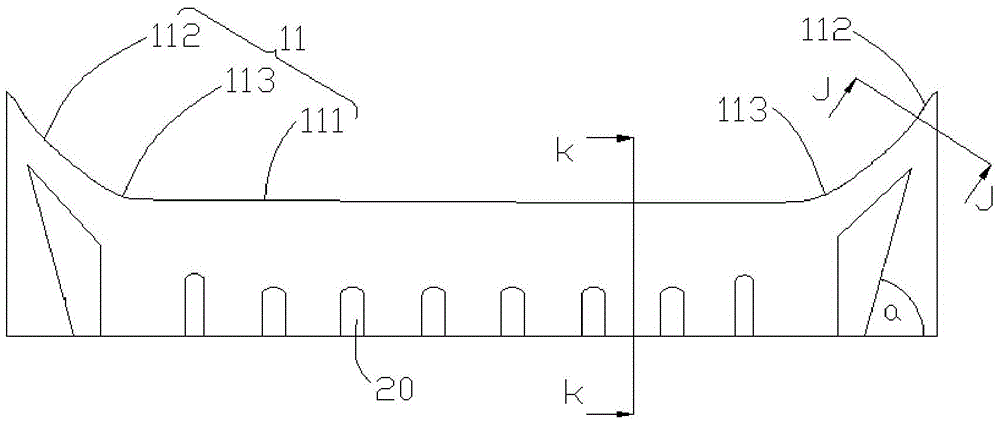

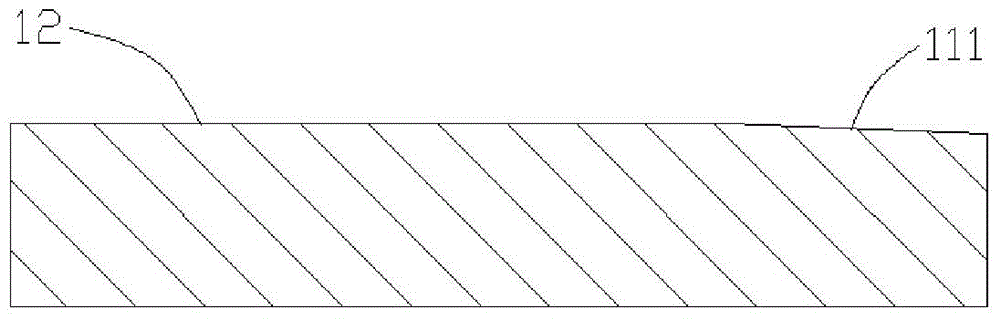

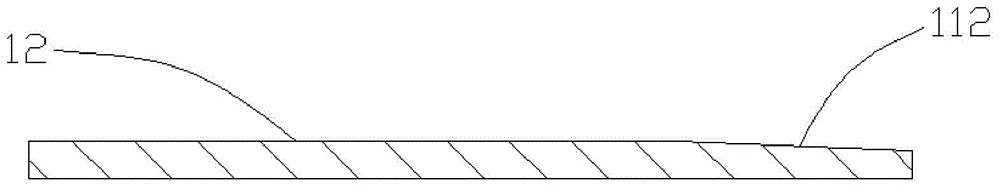

[0031] A steel mill casts a 230×1600mm medium-carbon niobium-containing continuous casting slab by using the method for reducing transverse cracks at the corners of niobium-containing steel provided by the embodiment of the present invention.

[0032] During the production process, the C content in molten steel is controlled to be 0.018%, and the Nb content is controlled to be 0.03%. The narrow side of the crystallizer is a double-taper crystallizer with a distance of 350mm from the upper mouth. The taper of the upper mouth of the mold is controlled at 1.46%, and the taper of the lower mouth of the mold is controlled at 1.0%. The flow velocity in the crystallizer wide surface and narrow surface water tank is controlled to be 8.7m / s and 8.4m / s respectively. The specific water volume of the secondary cooling zone is controlled at 0.73L / kg, and the ratio of the total water volume of cooling water in zones 2-4 to the total water volume of cooling water in zones 6-8 is 0.6. The me...

Embodiment 2

[0035]A steel mill casts a 230×1600mm medium-carbon niobium-containing continuous casting slab by using the method for reducing transverse cracks at the corners of niobium-containing steel provided by the embodiment of the present invention.

[0036] In the production process, the C content in the molten steel is controlled at 0.085%, the Nb content is controlled at 0.06%, the narrow surface of the crystallizer is a double-taper mold with a distance of 350mm from the upper mouth, the taper of the upper mouth of the mold is controlled at 1.56%, and the lower mold Mouth taper is controlled at 1.1%. The flow velocity in the crystallizer wide surface and narrow surface water tank is controlled to be 8.7m / s and 7.8m / s respectively. The specific water volume of the secondary cooling zone is controlled at 0.68L / kg, and the ratio of the total water volume of cooling water in zones 2-4 to the total water volume of cooling water in zones 6-8 is 0.65. The melting point of mold flux is c...

Embodiment 3

[0039] A steel mill casts a 230×1400mm continuous casting slab of niobium-containing steel by using the method for reducing transverse cracks at the corners of niobium-containing steel provided by the embodiment of the present invention.

[0040] In the production process, the C content in the molten steel is controlled at 0.07%, the Nb content is controlled at 0.05%, the narrow surface of the crystallizer is a double-taper mold with a distance of 350mm from the upper mouth, the taper of the upper mouth of the mold is controlled at 1.56%, and the lower mold Mouth taper is controlled at 1.1%. The flow velocity in the water tank on the wide side and the narrow side of the crystallizer is controlled in the range of 8.7m / s and 8.4m / s respectively. The specific water volume in the secondary cooling zone is controlled at 0.70L / kg, and the ratio of the total water volume of cooling water in zones 2-4 to the total water volume of cooling water in zone 6-8 is 0.7; the melting point of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com