Manufacturing device of antique furniture and manufacturing method thereof

A technology for making devices and furniture, which is applied in the manufacture of tools and wood processing appliances, etc., which can solve the problems of low flexibility, single shape and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

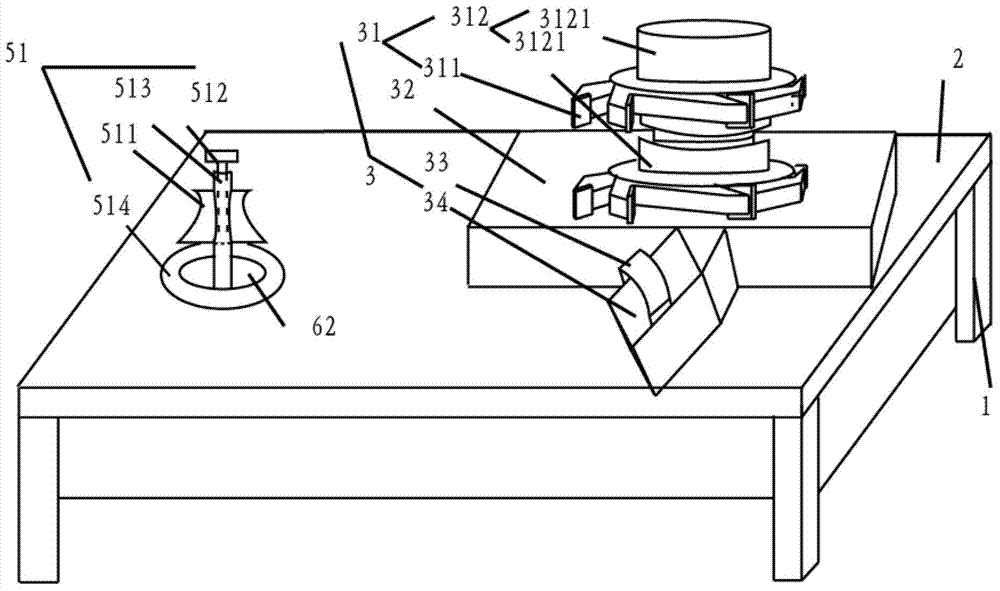

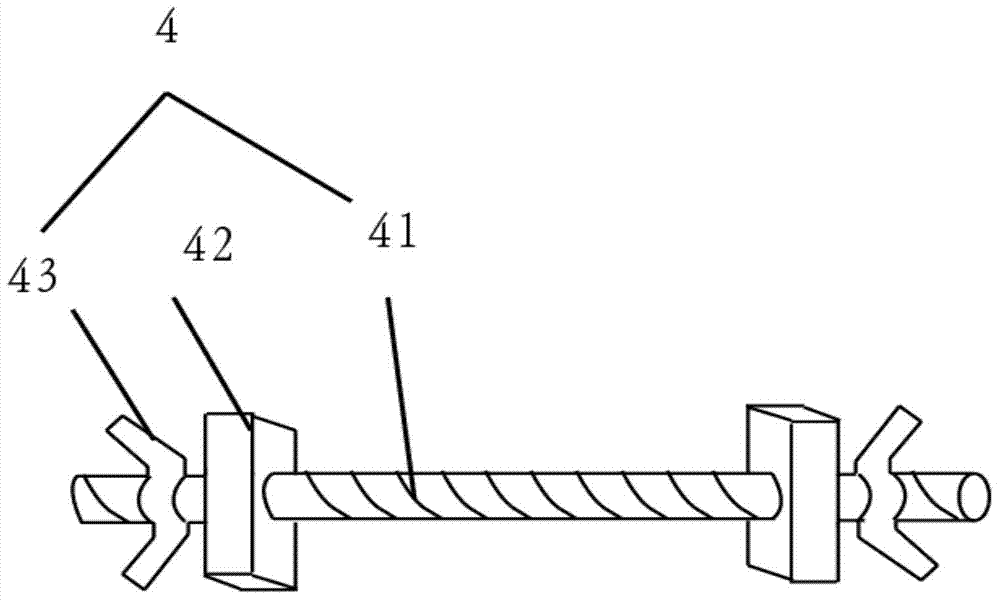

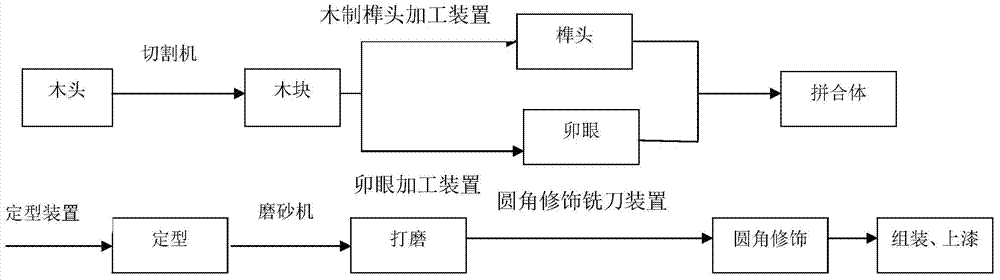

[0029] Such as Figure 1-2 As shown, the embodiment of the present invention provides a device for making antique furniture, including a frame 1, a workbench 2, a cutting machine, a wooden mortise processing device 3, a mortise processing device, a sanding machine, a shaping device 4, and a rounded corner modification Milling cutter device.

[0030] The workbench 2 is arranged on the frame 1 , and the workbench 2 is provided with through holes, and the through holes include a first through hole (not shown in the figure) and a second through hole 62 .

[0031] Cutters are used to cut wood into blocks. The wooden tenon processing device 3 includes a tenoning machine 31 , a guide plate 32 , a carrying device 33 and a clamping device 34 . The tenoning machine 31 includes two annular blades 311 , a motor and a lifting device 312 . Both the guide plate 32 and the carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com