Water-developable chemistry-free thermosensitive board and preparation method thereof

A chemical-free, water-developing technology, which is applied to printing plates, printing, and printing processes, can solve the problems of poor water-developing ability and printing durability of plates, and achieve improved water developing ability, improved printing durability, and strong Hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1)

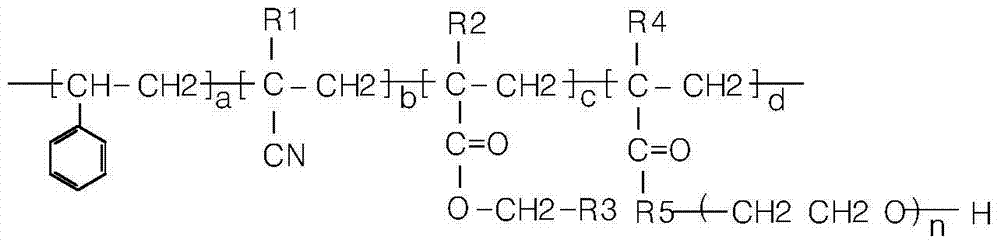

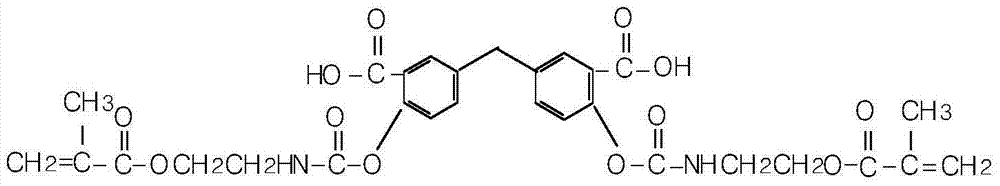

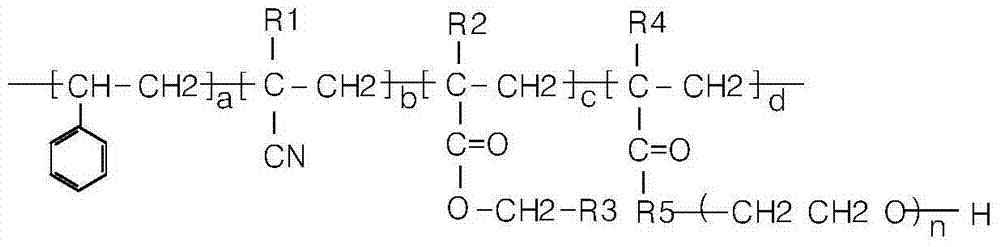

[0070] Embodiment (1) (water-soluble thermally cross-linked copolymer P01)

[0071] Add 333.3g of methyl ethyl ketone and 10g (10% by weight) of example compound D2 (n about 60) into a 1000ml four-necked flask equipped with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device, heat and stir evenly, and add dropwise at 90°C 70g (70% by weight) St (styrene), 10g (10% by weight) AN (acrylonitrile), 10g (10% by weight) example compound C2, 0.7g benzoyl peroxide BPO, adding time 20 minutes, and then After 7.5 hours of reaction, add 0.3g of benzoyl peroxide BPO, and continue to react for another 12 hours before ending. See attached table 1 for performance.

Embodiment (2)

[0072] Embodiment (2) (water-soluble thermally cross-linked copolymer P02)

[0073] Add 344.8g of methyl ethyl ketone and 10g (10% by weight) of the exemplary compound D4 (n about 50) into a 1000ml four-necked flask with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device, heat and stir evenly, and add dropwise at 80°C 60g (60% by weight) St (styrene), 20g (20% by weight) AN (acrylonitrile), 10g (10% by weight) of example compound C3, 0.7g of AIBN (azobisisobutyronitrile), and the addition time was 20 minutes After another 7.5 hours of reaction, 0.3g of AIBN (azobisisobutyronitrile) was added, and the reaction was continued for another 12 hours.

Embodiment (3)

[0074] Embodiment (3) (water-soluble thermally cross-linked copolymer P03)

[0075] Add 384.6g of methyl ethyl ketone and 10g (10% by weight) of example compound D4 (n about 40) into a 1000ml four-necked flask equipped with temperature-controlled heating, mechanical stirring, reflux and nitrogen protection device, heat and stir evenly, and add dropwise at 80°C 50g (50% by weight) St (styrene), 30g (30% by weight) AN (acrylonitrile), 10g (10% by weight) of example compound C2, 0.7g of AIBN (azobisisobutyronitrile), adding time 20 minutes After another 7.5 hours of reaction, 0.3g of AIBN (azobisisobutyronitrile) was added, and the reaction was continued for another 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com