Aramid powder composite injection molded caterpillar core gold and production process thereof

A technology of aramid fiber and powder, which is applied in the field of polymer composite profiles, can solve problems such as insufficient strength and short service life, and achieve the effects of increased strength, increased life, and improved strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

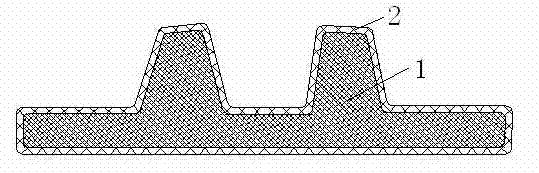

[0012] As shown in the figure, an aramid powder composite injection molded crawler core includes an aramid skeleton and a shell. The shell is an outer shell made of ultra-high molecular weight polyethylene, and the outer shell made of ultra-high molecular weight polyethylene is covered on the surface of the aramid skeleton.

[0013] The production process of the above-mentioned aramid powder composite injection molding crawler core gold, firstly, the aramid powder is processed by glue coating and static removal process, and then pressed at a high temperature of 130°C~180°C and a pressure environment of 10MPa~16MPa to form an aramid fiber skeleton, and then Under the pressure of 120℃~150℃ and 9MPa~12MPa, the ultra-high molecular weight polyethylene is coated on the surface of the aramid fiber skeleton, so that the ultrahigh molecular weight polyethylene and the internal aramid fiber powder are integrated.

[0014] In the present invention, the aramid fiber material is used as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com