Preparation method of epoxy alloy material

A technology of alloy material and epoxy alloy, which is applied in the field of preparation of epoxy alloy material, can solve the problems of limitation, failure to meet expectations, limited temperature adjustment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 5 parts by mass of polyethersulfone (PES) and 70 parts by mass of ethylene glycol glycidyl ether (EGDGE) were heated and dissolved evenly, and after cooling to room temperature, 25 parts by mass of 4,4'-diaminodiphenylmethane (DDM) were added And stir evenly, remove the air bubbles, pour into the mold, and pre-cure in the autoclave. Temperature 90°C, pressure 1MPa, curing for 4 hours. It was then post-cured at 130°C for 2 hours.

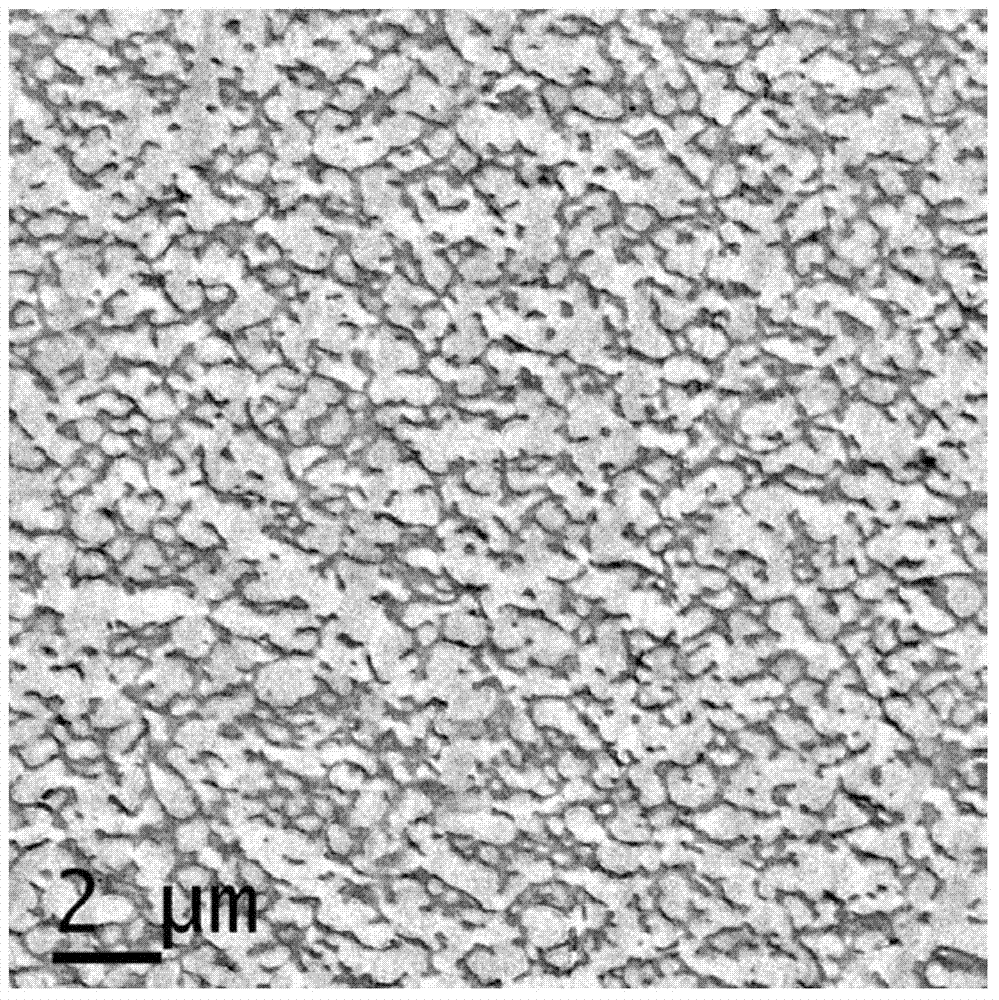

[0042] Phase separation distance: 1.7μm

[0043] Impact strength (Charpy): 4.7KJ / m 2 .

Embodiment 2

[0045] 5 parts by mass of polyethersulfone (PES) and 70 parts by mass of ethylene glycol glycidyl ether (EGDGE) were heated and dissolved evenly, and after cooling to room temperature, 25 parts by mass of 4,4'-diaminodiphenylmethane (DDM) were added And stir evenly, remove the air bubbles, pour into the mold, and pre-cure in the autoclave. Temperature 90°C, pressure 3MPa, curing for 4 hours. It was then post-cured at 130°C for 2 hours.

[0046] Phase separation distance: 736nm

[0047] Impact strength (Charpy): 5.2KJ / m 2 .

Embodiment 3

[0049] 5 parts by mass of polyethersulfone (PES) and 70 parts by mass of ethylene glycol glycidyl ether (EGDGE) were heated and dissolved evenly, and after cooling to room temperature, 25 parts by mass of 4,4'-diaminodiphenylmethane (DDM) were added And stir evenly, remove the air bubbles, pour into the mold, and pre-cure in the autoclave. Temperature 90°C, pressure 6MPa, curing for 4 hours. It was then post-cured at 200°C for 2 hours.

[0050] Phase separation distance: 350nm

[0051] Impact strength (Charpy): 5.7KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com