Stratum density measuring while drilling instrument based on deuterium-tritium accelerator neutron source

A technology of measuring while drilling and formation density, applied in the field of measuring while drilling and density logging while drilling, can solve the problems of low measurement result accuracy, influence density measurement accuracy, radioactive source pollution, etc., and solve the problem of low density measurement accuracy , Improve the measurement accuracy and reduce the effect of reducing radioactive hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

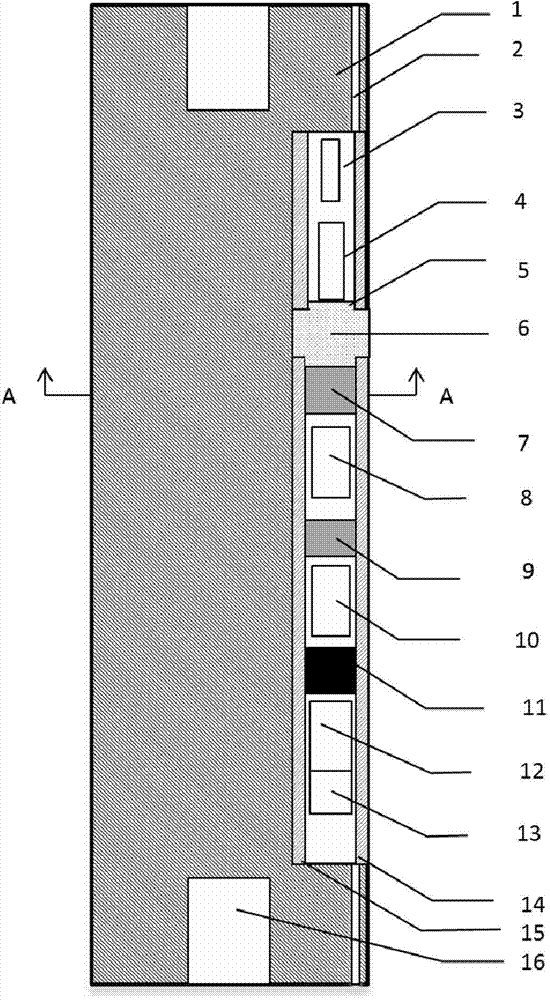

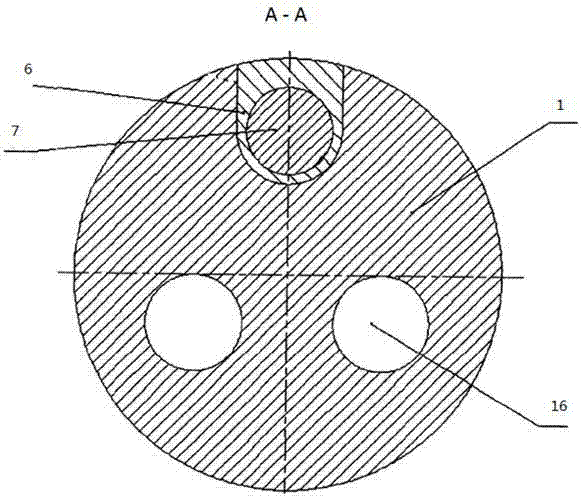

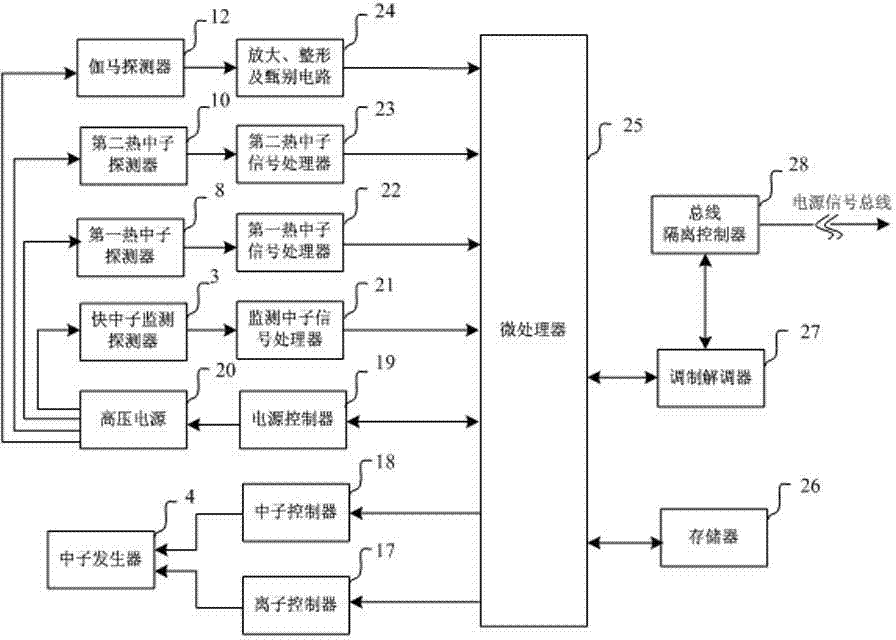

[0028] Now combined with the manual figure 1 , 2 and 3, the present invention is further described.

[0029] figure 1 Represents an axial section view of the instrument. The drill collar 1 is used as the installation skeleton of the instrument, and is a part of the downhole drilling tool, located behind the drill bit or the deflection tool. A U-shaped groove 15 is opened on the side of the drill collar 1, and the generator module anti-pressure cylinder 5 and the detector module installation frame 14 are installed from top to bottom in the U-shaped groove 15, and their wall thickness should meet the high pressure resistance of downhole mud According to the requirements, the wire hole 2 is set to lead to the U-shaped groove 15. The fast neutron monitoring detector 3 and the neutron generator 4 are installed in the anti-pressure cylinder 5 of the neutron generator module from top to bottom, and the neutron generator 4 adopts a deuterium-tritium reaction accelerator neutron so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com