Hydraulic coupler of instant response type common-rail oil injector

A technology of hydraulic coupling and common rail injector, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of low service life of common rail injectors, achieve easy processing, reduce weight, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

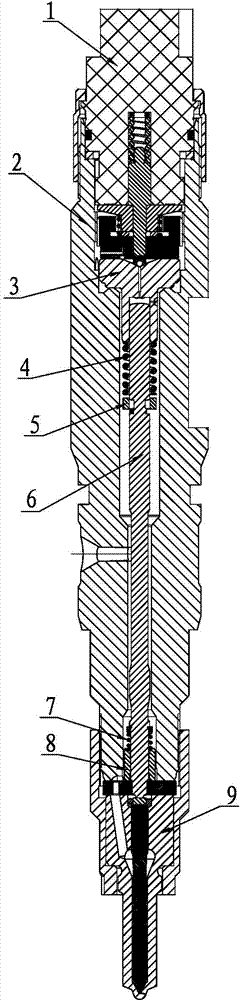

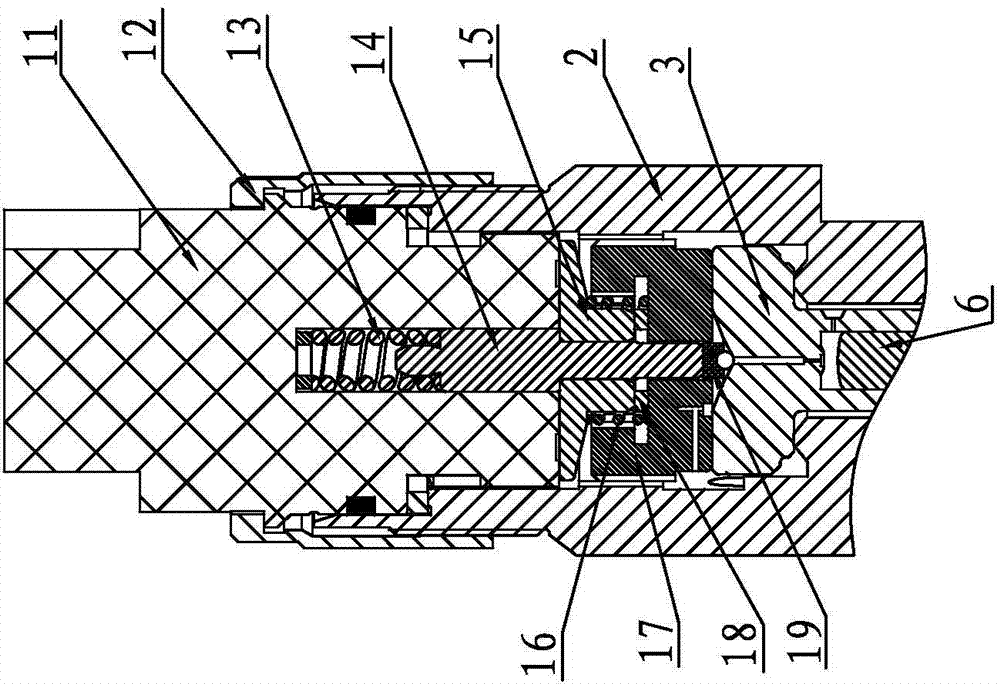

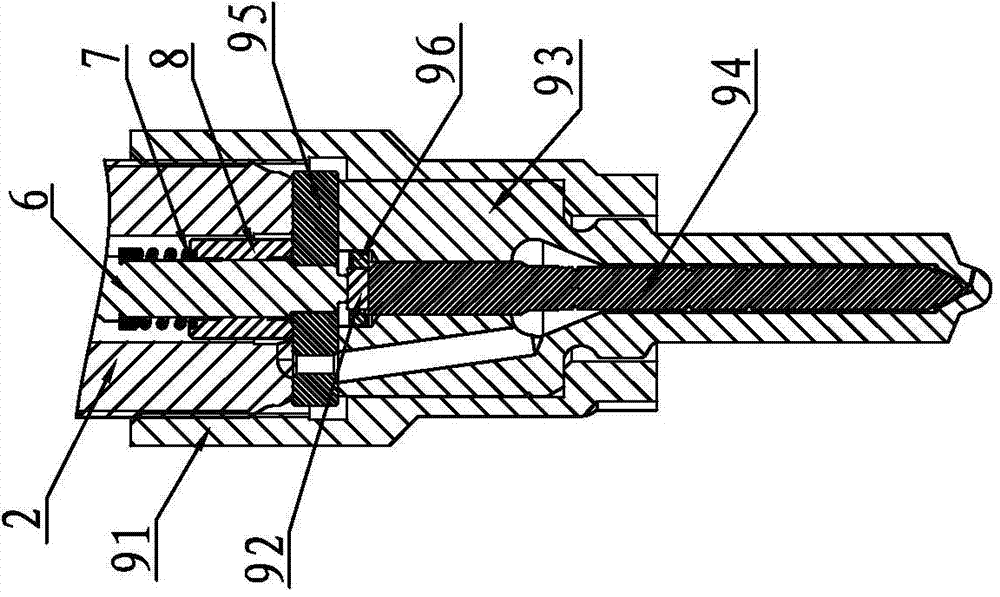

[0023] Embodiment 1: A kind of high-pressure common rail fuel injector without static leakage, such as Figure 4 ~ Figure 6As shown, it includes electromagnetic injection control valve 1, injector body 2, valve sleeve 3, valve stem return spring 4, spring seat 5, valve stem 6, coupling spring 7, coupling sleeve 8 and hydraulic coupling 9, The electromagnetic injection control valve 1 is composed of an electromagnet 11, an electromagnet tight cap 12, an electromagnet spring 13, an armature rod 14, an armature 15, an armature return spring 16, a guide valve seat body 17a, a valve sleeve pressing cap 17b, and an adjustment washer 18 and the control ball assembly 19, the electromagnet spring 13 is installed in the center hole of the electromagnet 11, the upper section of the armature rod 14 is set in the inner hole of the electromagnet spring 13, and the upper guide section of the armature rod 14 is installed in a clearance fit manner In the center hole of the electromagnet 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com