Hydraulic oil tank for mulch applicator

A technology of hydraulic oil tank and laminating machine, which is applied in the direction of oil supply tank device, mechanical equipment, fluid pressure actuating device, etc., can solve the problems of increasing cost, prolonging processing cycle, hidden danger of oil leakage in oil tank, etc., and achieving low production cost, The effect of improving strength and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

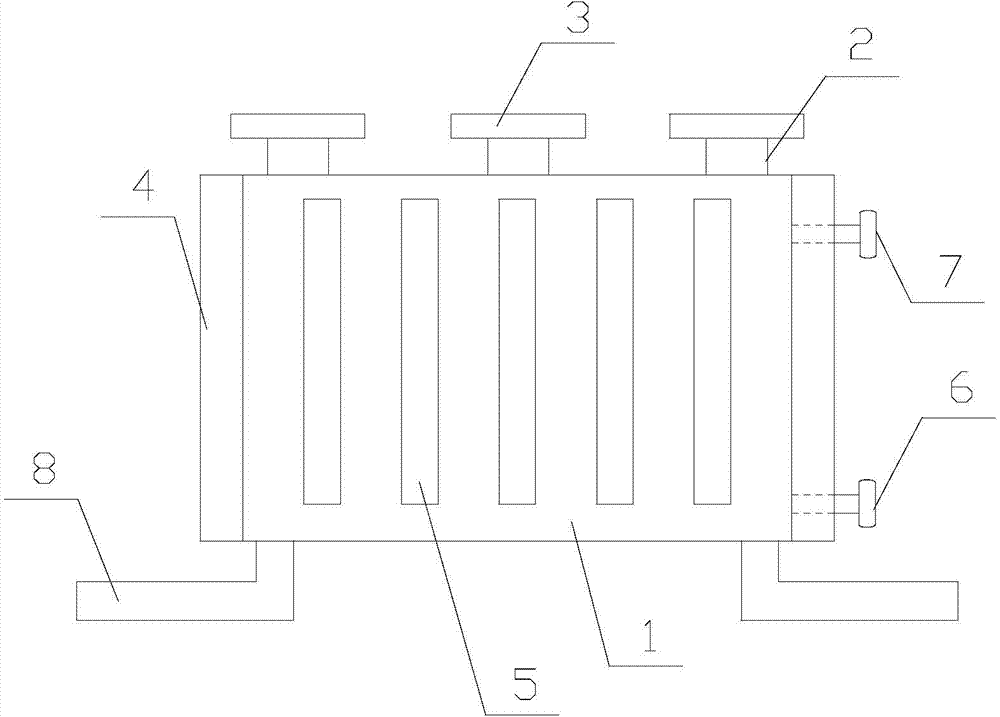

[0012] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0013] Such as figure 1 The hydraulic oil tank for the laminating machine shown has a box body 1 with a rectangular structure, and several connecting shells 2 are evenly distributed on the top surface of the box body 1, and a heat sink 3 is arranged on the connecting shell 2. The left side of the box body 1 and The right side is provided with a plurality of mutually parallel ribs 4, and several ribs 5 are evenly distributed on the front side and the rear side of the box body 1. The ribs 4 and the ribs 5 are integrally formed with the box body 1 to improve the The strength of the box body 1 is also conducive to heat dissipation. The lower end of the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com