High voltage electric loop control device for electric automobile

A loop control, electric vehicle technology, applied in general control systems, program control, computer control, etc., can solve the problems of reducing the safety factor of electric vehicles, no relays, and inability to judge the adhesion state of relays, so as to reduce the risk of electric shock to personnel, Improve the safety factor of the whole vehicle and reduce the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

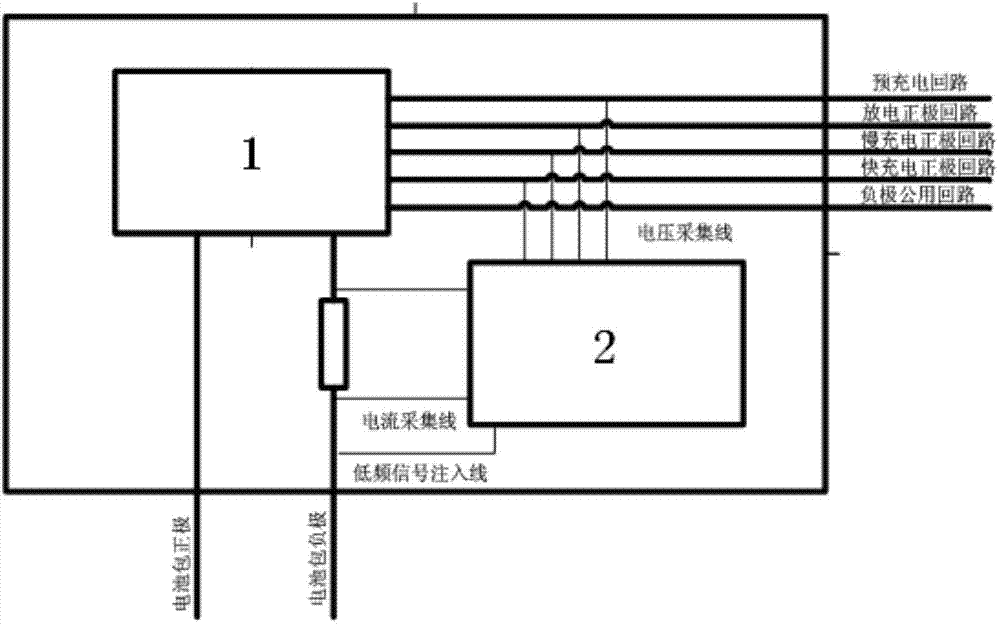

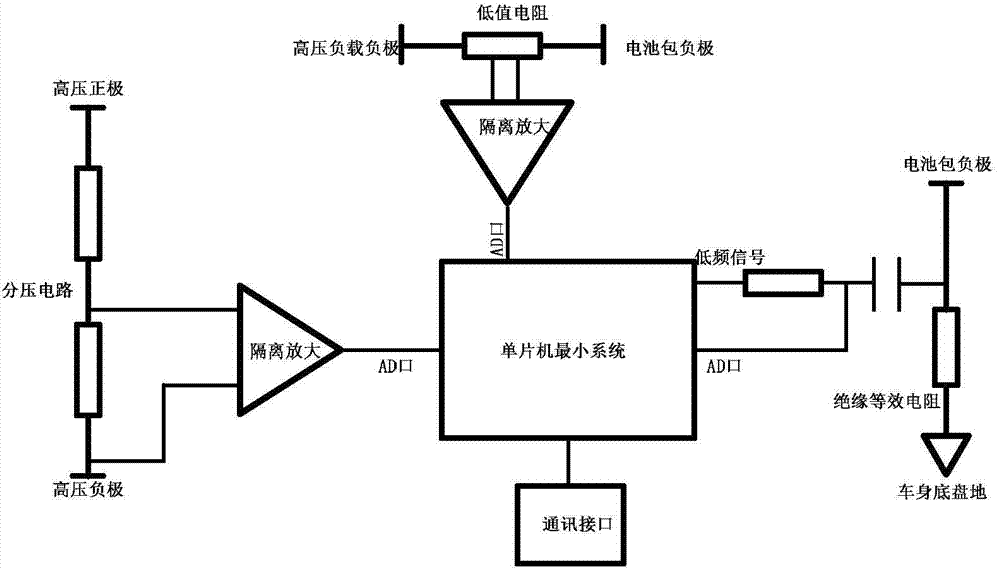

[0017] The present invention integrates the high-voltage circuit on-off control unit 1 and the high-voltage electric circuit state detection unit 2, and the high-voltage circuit on-off control unit 1 completes the on-off control of the pre-charging circuit, the discharging circuit, the slow charging circuit, and the fast charging circuit; The high voltage circuit state detection unit 2 completes the detection of high voltage voltage, current, insulation resistance and relay state parameters.

[0018] The high-voltage circuit on-off control unit 1 can realize the on-off control functions of the high-voltage pre-charging circuit, the high-voltage discharging circuit, the high-voltage slow charging circuit, and the high-voltage fast charging circuit. The pre-charge on-off control loop is composed of a pre-charge relay, a pre-charge resistor, and a negative relay. The pre-charging circuit can suppress the generation of inrush current and protect the high-voltage components of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com