Provision of degassed water

A technology of degassing and degassing devices, applied in liquid degassing, separation methods, beer brewing, etc., can solve the problems of less efficient and flexible facilities and increased energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

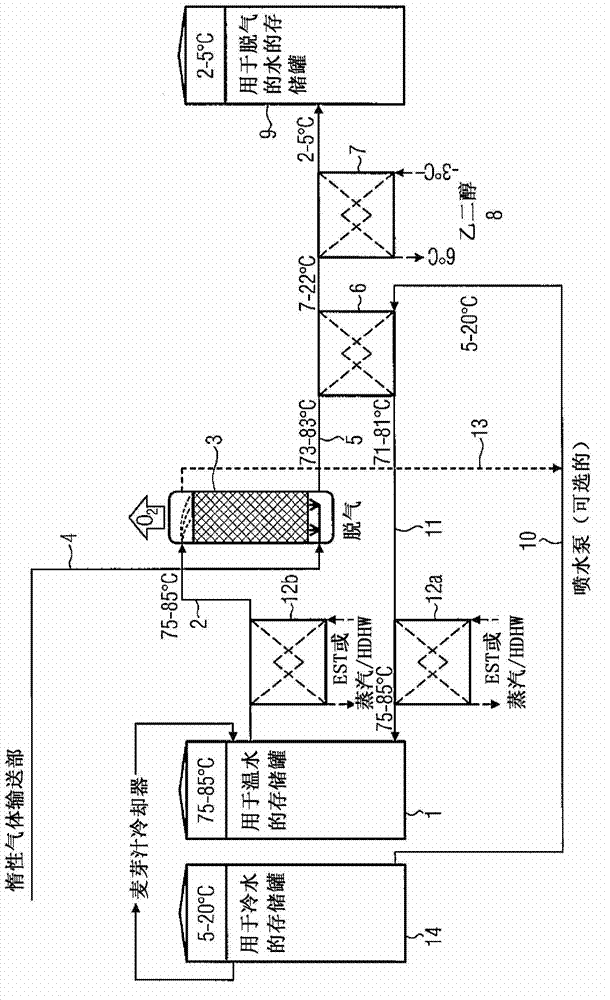

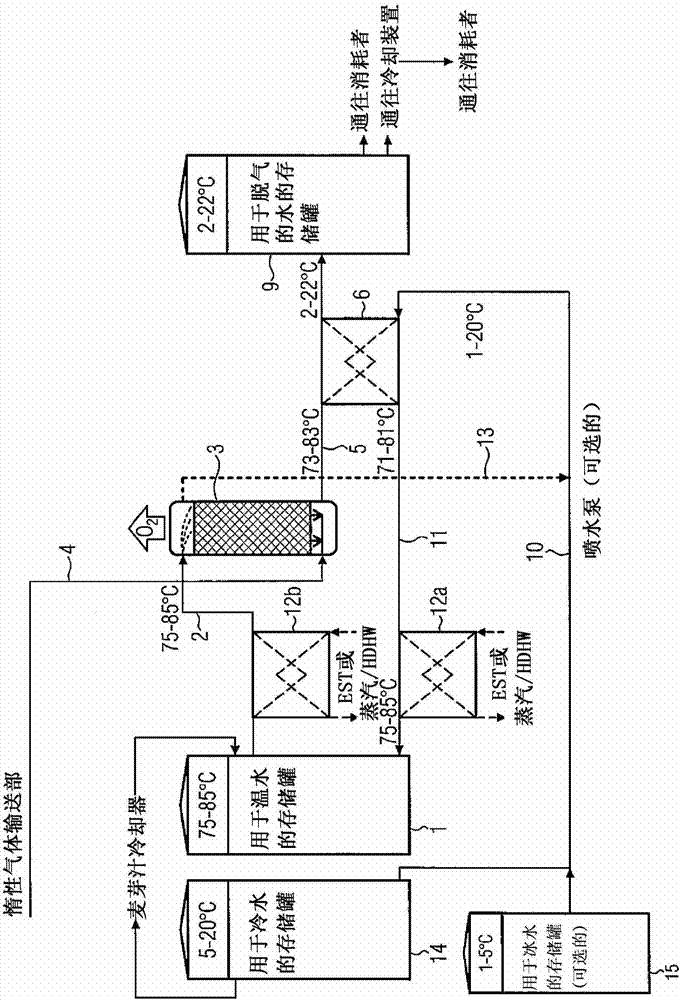

[0036] exist figure 1 An exemplary construction scheme for a plant according to the invention is shown in (see also figure 2 ). Depend on figure 1 and figure 2 Exemplarily occurring temperatures are known. Storage tank 1 for warm water stores warm (about 75 to 85°C) water set for degassing. In the storage tank 1 for warm water, the warm water is pasteurized. Oxygen (O 2 ) from the warm water in which it was stored. The warm water to be degassed is fed via line 2 to a degassing device 3 by means of a pump not shown. In contrast to the prior art, therefore, warm water is provided for degassing in order to obtain degassed water. In the case of atmospheric pressure of 1 bar, 10 mg of O is combined in water temperature of eg 15 °C 2 / l, while only 3.1mg O 2 / l. Warm water is thus provided for degassing in order to obtain degassed water, which enables a significantly simpler and more efficient degassing than the provision of cold water.

[0037] The positions of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com