Silicone rubber ball nozzle

A technology of silicone rubber and ball nozzles, which is applied in the field of ball nozzles and silicone rubber nozzles. It can solve the problems of difficult inner liner bonding and cumbersome processing and implementation, and achieve the effects of good fixation, high compactness and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

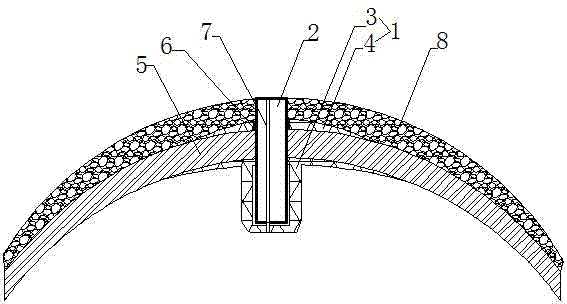

[0014] Such as figure 1 The silicone rubber ball mouth shown includes a ball head 1 and a ball seed 2, the ball seed 2 is made of silicone rubber, the ball head 1 is made of natural rubber; the ball seed 2 is a cylindrical structure; the The ball head 1 is composed of an inner ball head 3 and an outer ball head 4; the ball head 1 is embedded in the inner container 5; the inner ball head 3 is closely attached to the inside of the inner container 5; On the outer side of the liner 5.

[0015] Wherein, the inner ball head 3 is an arc surface convex structure; the outer ball head 4 is an arc surface structure; the outer ball head 4 and the ball seed 2 are a zigzag structure 6 fitted with each other; the ball seed An air-filling hole 7 is provided on the axis of the ball head 2; a ball seed passage hole 8 is opened in the middle of the ball head 1; the ball head 1 and the ball seed 2 are bonded to each other.

[0016] The production process is as follows:

[0017] 1. Making the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap