Welding method of flange plate and web plate of q390d steel crane girder in heavy work system

A welding method and flange plate technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems that welding methods cannot be borrowed, and achieve the effects of reducing energy consumption, improving welding quality, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

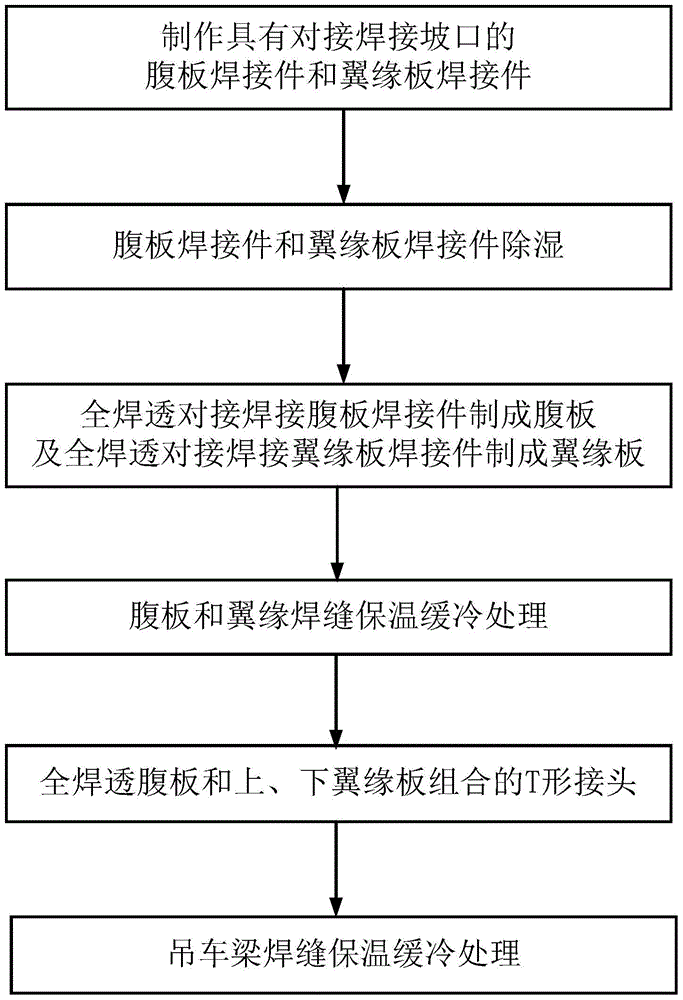

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

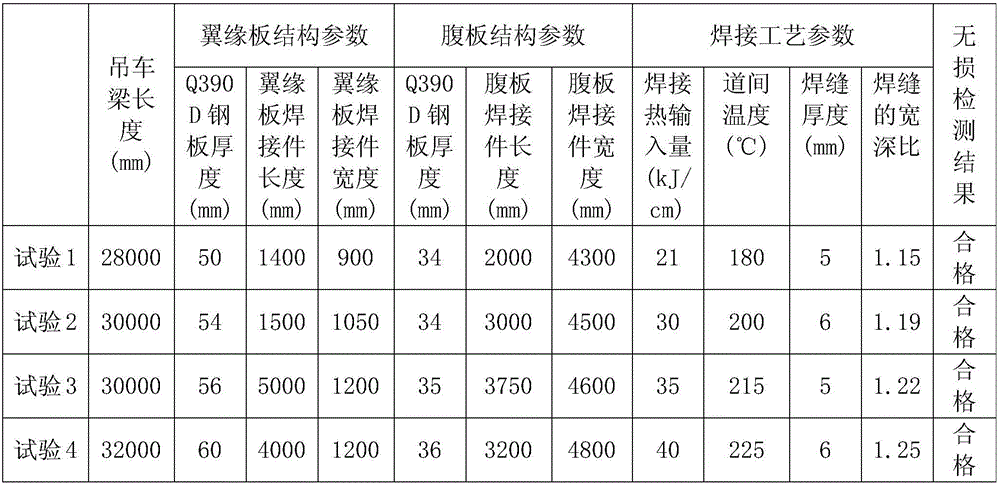

[0033] like figure 1 As shown, the welding method of the heavy-duty working system Q390D steel crane beam flange plate and web plate of the present invention, the Q390D steel plate with a thickness of 50 to 60 mm is cut into a flange plate weldment, and the Q390D steel plate with a thickness of 34 to 36 mm is cut into The web weldment, followed by the full penetration butt welded web weldment to make the web, the full penetration butt welded flange plate weldment to make the flange plate, the full penetration T-welded combination welded web and flange plate will Welding of web and flange plates into crane girders; including fabricating web and flange plate welds with butt weld grooves, dehumidification of web and flange plate welds, full penetration butt weld web welding Welding parts are made into web and full penetration butt welded flange plate Weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com