Vehicle-mounted operation type tyre disassembling and assembling machine

A tire dismounting machine and operation technology, which is applied in tire installation, tire parts, vehicle parts, etc., can solve the problems of inconvenient operation, inconvenient operation, 5-heavy cantilever, etc., so as to improve flexibility and convenience, and facilitate adjustment Use, the effect that flexibility is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

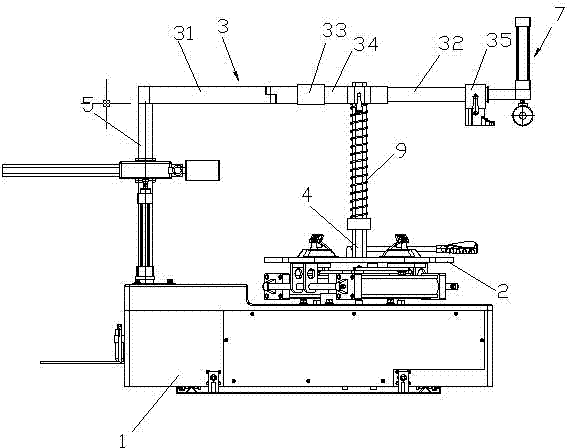

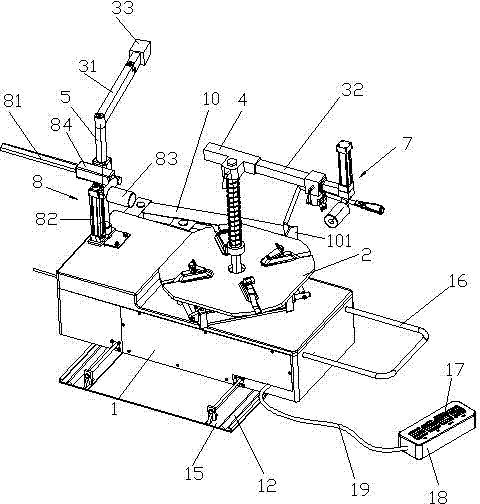

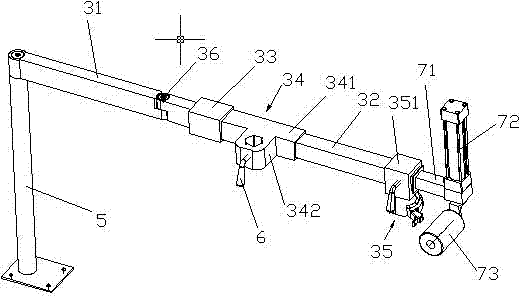

[0027] Embodiment 1: as Figure 1 to Figure 4 As shown, a vehicle-mounted operation type tire changer, a vehicle-mounted operation type tire changer, includes a fuselage 1, a central column 4 and a tire clamping turntable 2 are installed on the fuselage 1, and the center column 4 slides upward and is equipped with The cantilever 3 is provided with a lifting sleeve 34 that can be relatively fixed to the central column 4 through a locking structure. The locking structure in this embodiment is a locking screw 6, which is used as a handle after being bent. The screw rod end passes through the lifting sleeve 34 to abut against the central column 4 so that the lifting sleeve 34 and the central column 4 are fixed. The tire clamping turntable 2 for clamping the tire hub is also installed on the fuselage 1, and the central column 4 passes through the clamping tire rotating disc 2 and can do lifting motion. The cantilever 3 includes a rear arm 32 and a forearm 31 . The front arm 32 an...

Embodiment 2

[0035] Embodiment 2: as Figure 6 As shown, the structure and mutual connection relationship of each component in this embodiment are basically the same as that of Embodiment 1, the difference is that the track 12 is a linear guide rail, and the track 12 cooperates with the slider 122 at the bottom of the fuselage, and the inside of the slider 122 Balls are provided, and the linear guide including the slider is a set of existing products, which can be directly purchased in the market. On the bed 1, two tool boxes 20 are also provided, and the switch 21 for operating the press roller cylinder is arranged on the press roller cylinders of the two press roller mechanisms. 1 button 22 for movement.

[0036] The present invention is used like this:

[0037] First, pre-separate the tire and the wheel hub: operate the switch to make the push-pull cylinder 13 work, and the push-pull cylinder 13 pushes the fuselage 1 to move away from the tire pressure swing arm 10, so that the tire c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com