Method and device for receiving pipe jacking machine under condition of high water pressure complicated geological conditions

A technology of complex geological conditions and receiving methods, applied in the receiving field of pipe jacking machines, can solve problems such as threats to the safety of buildings and underground facilities, high construction safety risks, and failure of pipe jacking projects, so as to achieve wide applicability of the stratum and reduce reinforcement and precipitation Effect of construction and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

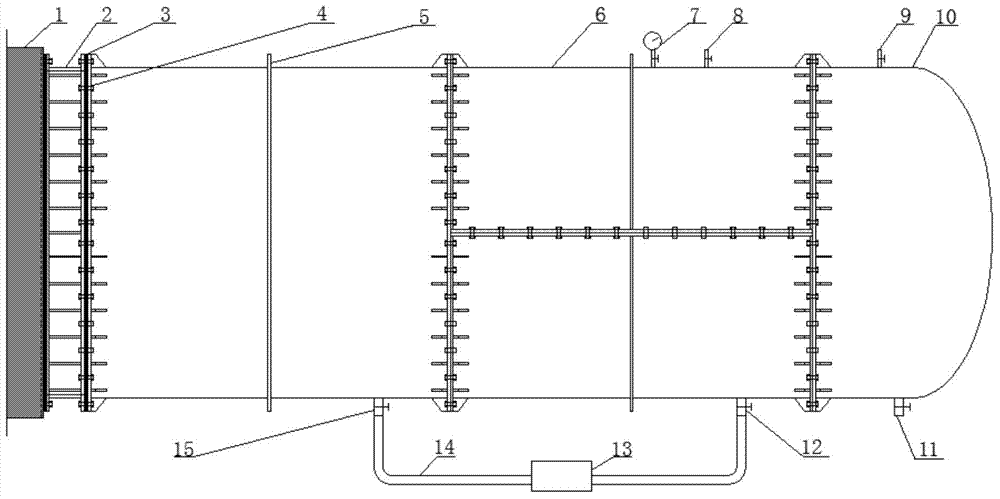

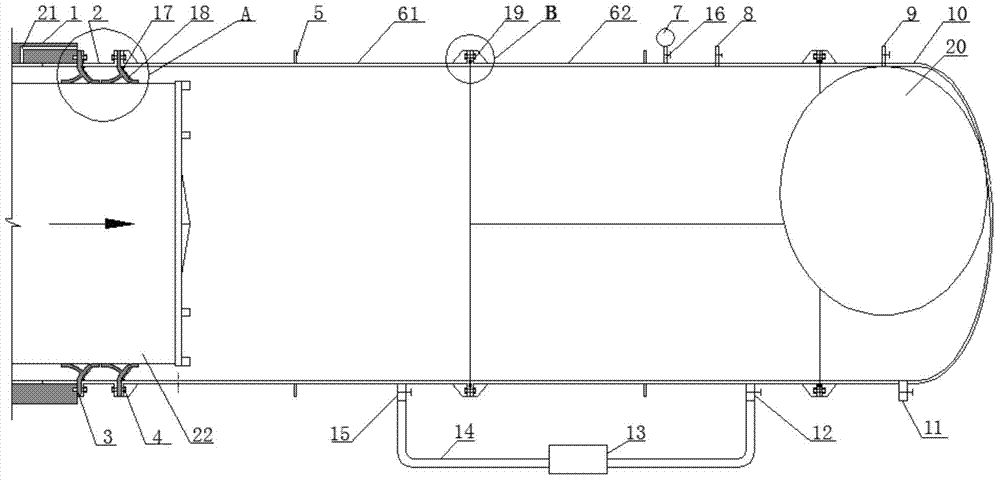

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] The method for receiving a pipe jacking machine under high water pressure and complex geological conditions provided by the present invention comprises the following steps:

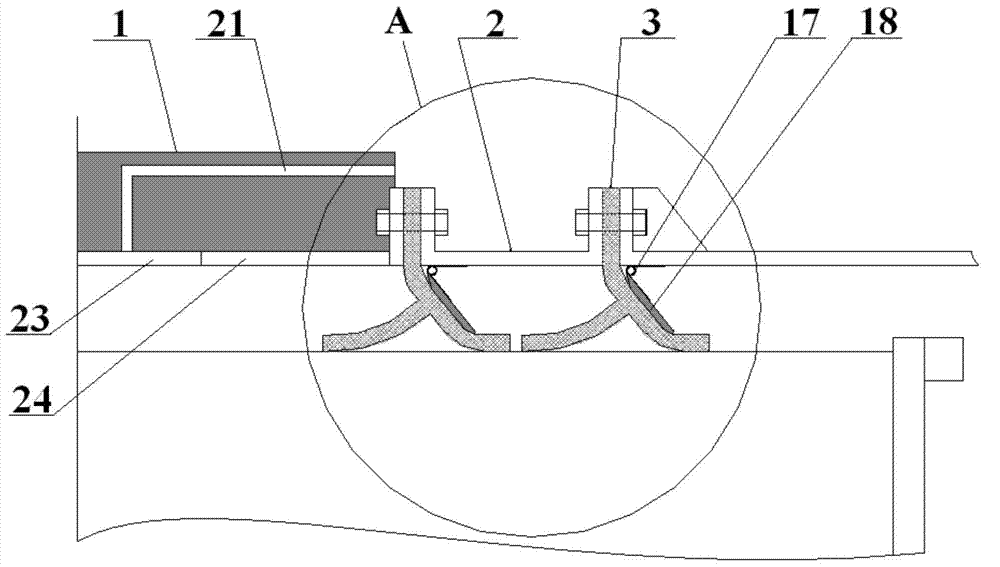

[0033] (1) Pre-install the grouting channel in the opening wall of the receiving well, embed the orifice pipe at the position where the pipe jacking machine is scheduled to break the wall in the opening wall of the receiving well, and install a receiving pipe with a gas valve and a liquid valve in sequence at the front end of the orifice pipe. cabin and a pressure stabilizing cabin with a liquid overflow valve and a built-in air bag. A sealing ring is installed between the receiving cabin and the orifice pipe to seal the gap between the receiving cabin and the wall of the opening of the receiving well. The inner ring of the sealing ring extends into the receiving tank. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com