Liquid crystal display laser backlight source

A technology of liquid crystal display and laser light source, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of uneven light intensity, high cost, complex structure of backlight source, etc., achieve uniform light intensity, simplify structure, and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

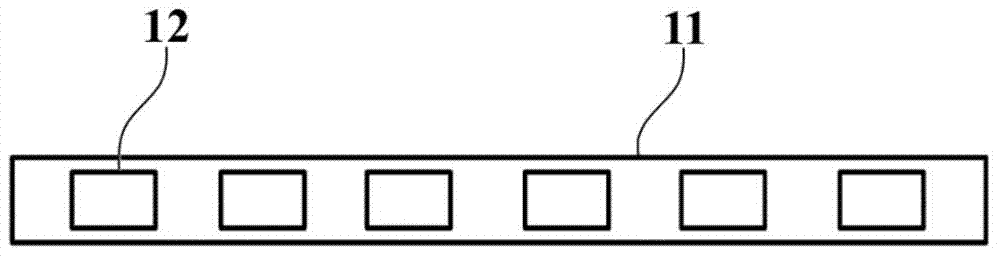

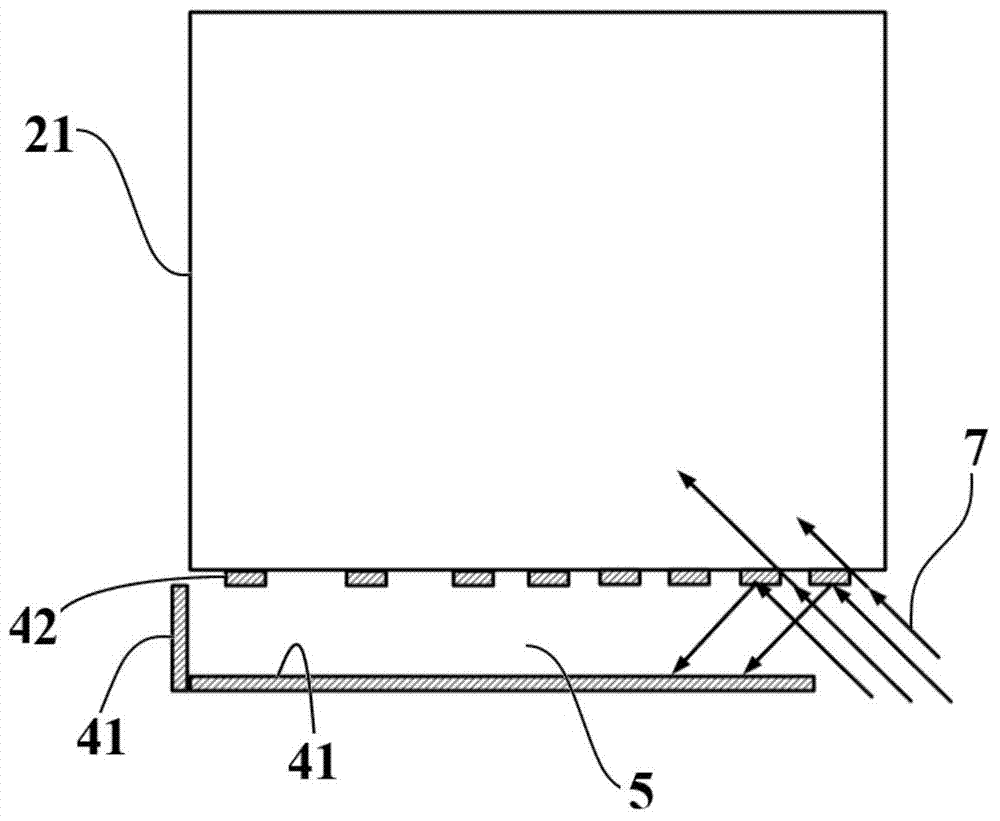

[0033] Figure 2(a) , 2(b) and 2(c) show the side-lit backlight.

[0034] The light guide cavity 5 is a hollow cylinder with a rectangular cross section. The incident light 7 is obliquely incident into the cavity from the incident surface at one end of the light guide cavity 5, and the light inside the light guide cavity 5 overflows into a linear shape from the light exit surface, so that the incident light 7 can be converted into a quasi-continuous line light source; The continuous line light source is coupled into the light guide plate 21 from one side of the light guide plate 21, and the light guide plate 21 converts the incident line light source into a surface light source.

[0035] The light guide cavity 5 is pasted with a reflective film as the reflective layer of the light guide cavity 5 except the incident surface, wherein the light emitting surface is pasted with a discrete reflective film 42, and the other faces are pasted with a continuous reflective film 41, and...

Embodiment 2

[0038] image 3 Shown is a double-beam incident structure, and the difference from Embodiment 1 is that the incident light 7 is incident from both ends of the light guide cavity 5, and the incident surfaces are two end surfaces.

[0039] The discrete reflective film 42 on the light exit surface of the light guide cavity 5 is directly attached to the side of the light guide plate 21, and the light guide plate 21 is used as a support structure for the reflective film.

[0040] The reflective film uses a semi-transparent and semi-reflective film, and the reflection method can be selected from specular reflection or diffuse reflection.

Embodiment 3

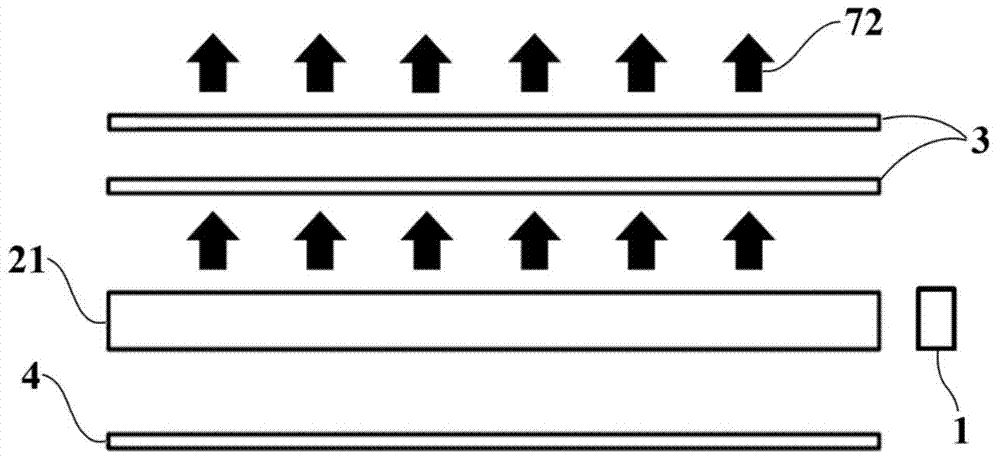

[0042] Figure 4(a) and 4(b) Shown is a direct-type backlight, and Figure 4(b) is the structure of Figure 4(a) turned 90° horizontally.

[0043] The light guide cavity 5 is a flat hollow structure, including top, bottom and side surfaces; the incident light 7 of the direct-type backlight is different from that of the side-type backlight. Simultaneous oblique incidence, the two opposite sides are incident surfaces; the top surface is the light-emitting surface, which is a transparent substrate 6 with a discrete reflective film 42 attached, the transparent substrate 6 does not absorb visible light, and plexiglass material can be used; obliquely incident light Reflected by the discrete reflection film 42 on the light exit surface, it becomes reflected light 70 , and part of it passes through the transparent substrate 6 to become transmitted light 71 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com