Swirl less-gas pulverized coal burner

A gas burner and burner technology, which is applied to burners, burners, burners burning powder fuel, etc., can solve the problems of poor coal applicability, low burner output, and poor combustion stabilization effect, and achieve maintenance costs. Low, strong burning, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

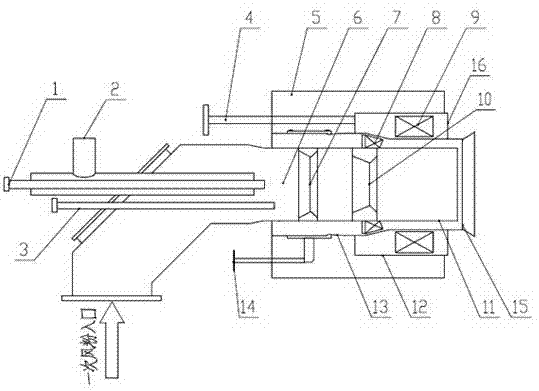

[0016] Such as figure 1 As shown, a kind of swirling flow gas-less pulverized coal burner includes a gas burner 1, a combustion chamber 11, an internal secondary air device 13, an external secondary air device 12 and a secondary air box 5, a combustion chamber 11, an internal secondary air The axis lines of the wind device 13, the external secondary air device 12 and the secondary air box 5 all overlap. The outside of the combustion chamber 11 is an inner secondary air device 13, the outer side of the inner secondary air device 13 is an outer secondary air device 12, and the first three are all in the secondary air box 5.

[0017] Wherein, the high-energy igniter 3 is used to ignite the natural gas after the gas burner injects gas to form a high-temperature central flame to further ignite the pulverized coal.

[0018] Combustion chamber 11 along the air powder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com