Shaping device for maintaining original shape of dried golden camellia flowers

A technology for golden camellia and dried flowers, which is applied in the field of setting equipment for maintaining the original state of golden camellia dried flowers, can solve problems such as breakage, petals are not easy to shape, and affect quality, etc., and achieve the effects of increasing unit circulation, speeding up drying speed, and shortening time differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

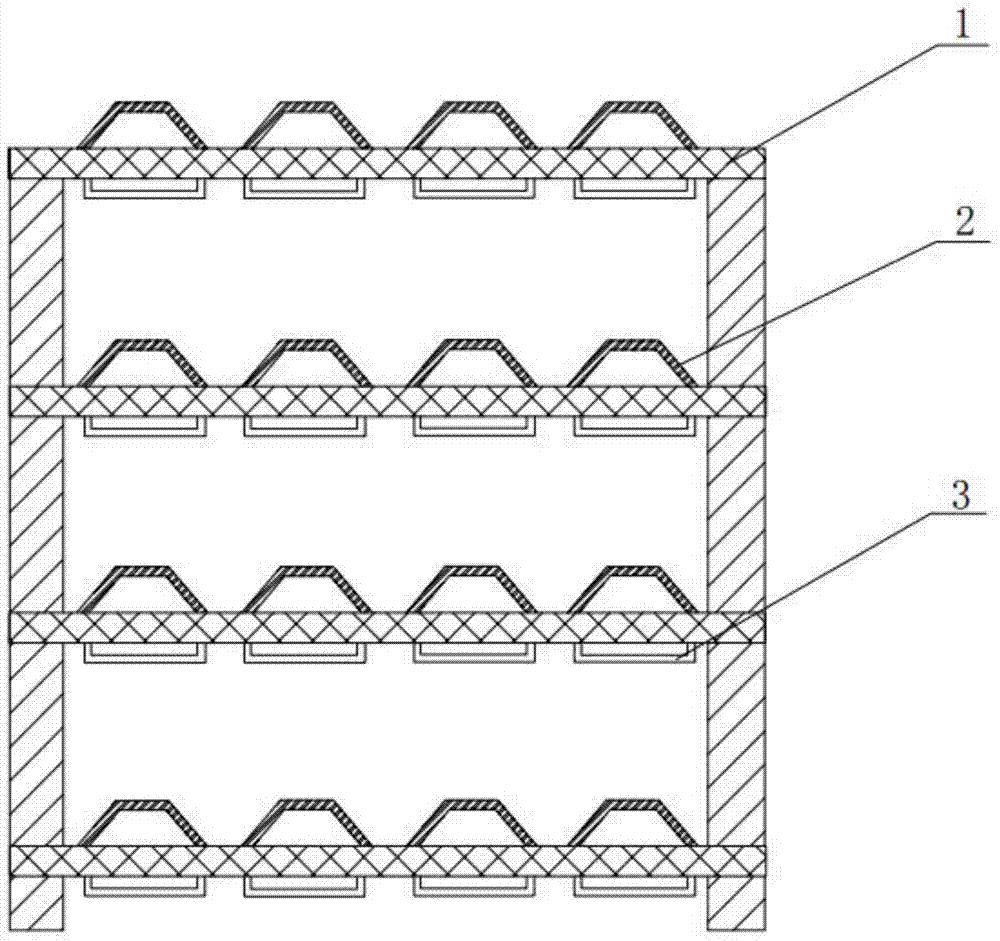

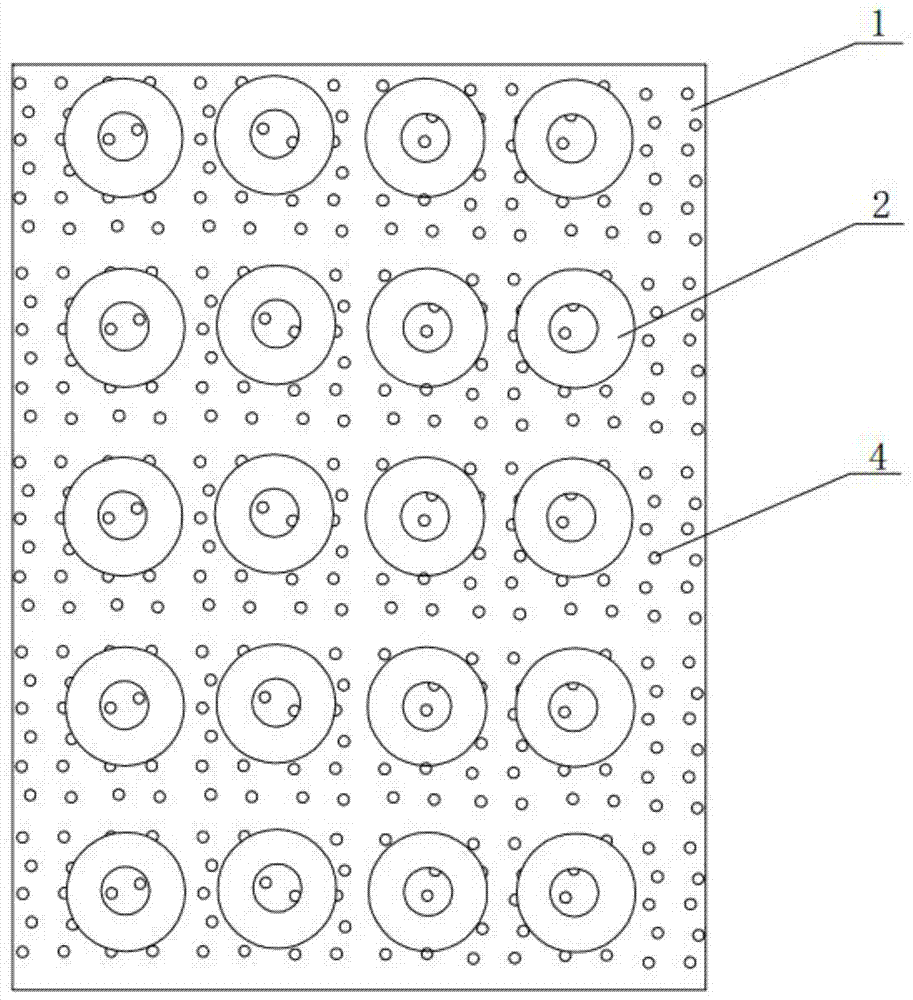

[0013] Such as figure 1 , 2 As shown, it is a sizing device for keeping the original shape of dried camellia camellia flowers according to the present invention, which includes a multi-layer vertical partition 1 and a flower holder 2 arranged on the partition 1, and the partition 1 and the holder 2 are both Made of high temperature resistant material. The distance between the adjacent partitions 1 is 18cm, and the partitions 1 are provided with evenly arranged air holes 4, the diameter of the air holes 4 is 0.5cm, and the distance between the centers of the adjacent air holes 4 is 1.5cm. The supporting flower tube 2 is a hollow circular platform structure with both ends open, and the bottom angle of the section crossing the axis is 30-50°, preferably 40°; its height is 1.5-2.2 cm, preferably 1.8 cm. The support tubes 2 are arranged on the partition 1 in a matrix form, and the bottom of the partition 1 is facing the support tube 2. There is an annular exhaust pipe 3 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com