Device for insulating material surface flashover experiment and using method thereof

A technology of insulating materials and flashover along the surface, which is applied in the direction of testing dielectric strength, etc., can solve the problems of difficult structure control, waste of working time, environmental pollution, etc., and achieve the effect of reducing the number of opening times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

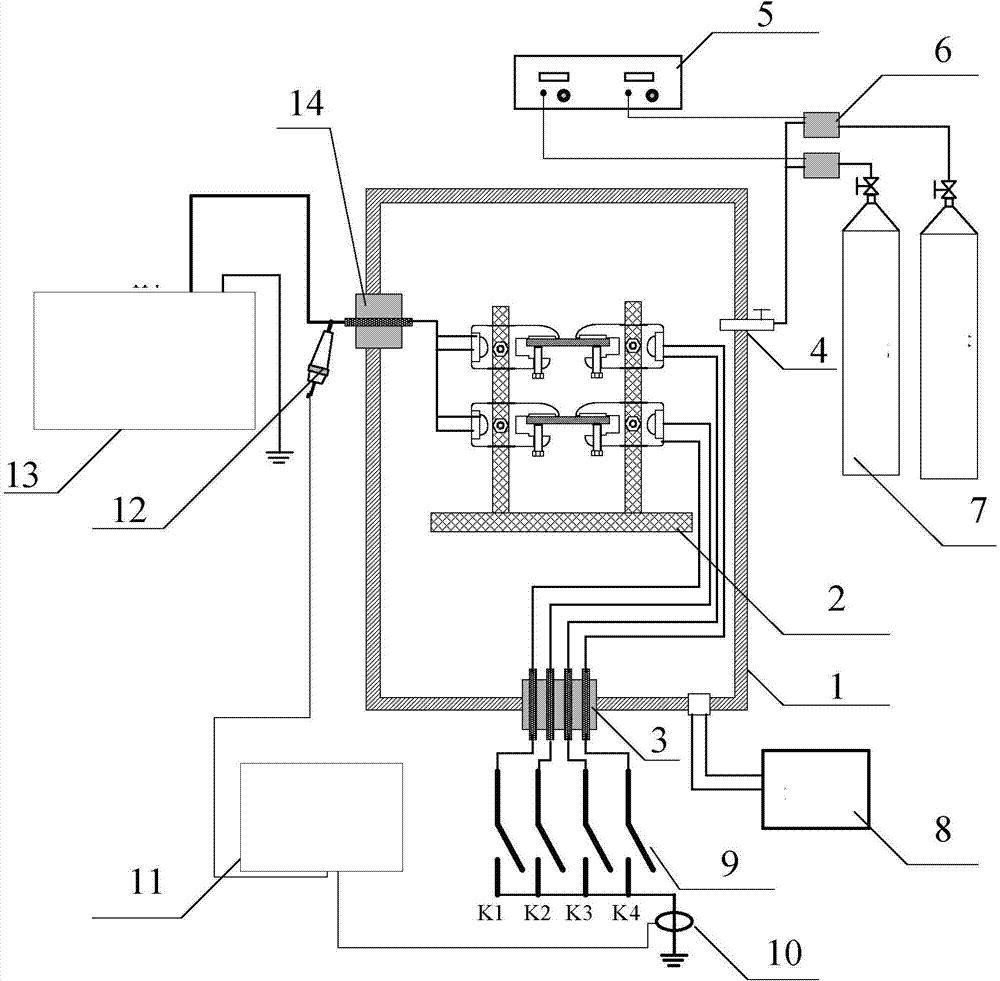

[0035] Such as figure 1 As shown, the device of the present invention comprises a test cavity (1), a support device (2), a flowmeter (5), a gas cylinder (7), a molecular pump (8), a low pressure switch (9), an oscilloscope (11), a high pressure Power supply (13) etc. Among them, the experimental cavity (1) is a closed cavity made of stainless steel, and there are high and low pressure sleeves, suction and air inlets, and observation windows on the cavity, and the flow meter (5) is a gas flow meter. The connected solenoid valve (6) is used to adjust the flow rate of the incoming gas. Gas cylinders (7) consist of two cylinders, one carrying SF 6 gas, another carrying experiment required with SF 6 The mixed gas and the two kinds of gas are controlled by the solenoid valve (6) and the flow meter (5) connected to it to control the inflation speed, and finally reach the required experimental gas mixing ratio. The cylinder (7) is filled with SF 6 Gas, the molecular pump (8) is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com