Frequency selective surface

A frequency-selective surface and material technology, applied in the direction of the radiation unit cover, waveguide devices, electrical components, etc., can solve the problems of small microwave absorption bandwidth, inconvenient conformal shape, large FSS volume, etc., to achieve small structure size, easy installation, The effect of a wide absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The performance of the FSS structure is not only related to the size and periodic arrangement of the FSS units, but also related to the selected material itself. Traditional FSS materials are metal or conductor coatings, semiconductor films and nano-films can also be used as FSS materials, and more novel ones can be realized through conductive ink coatings and slow-drying water. But no matter which material is used, this material can be equivalent to a model with a specific relative permittivity and a specific conductivity.

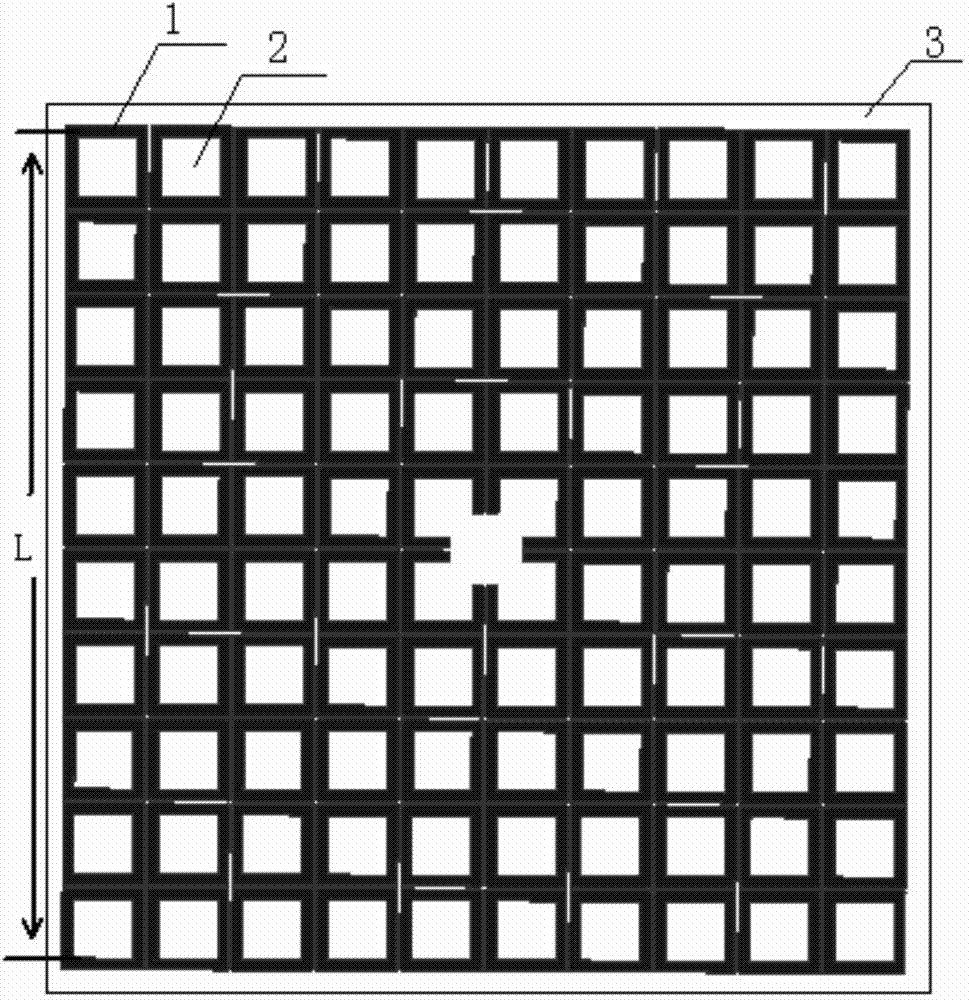

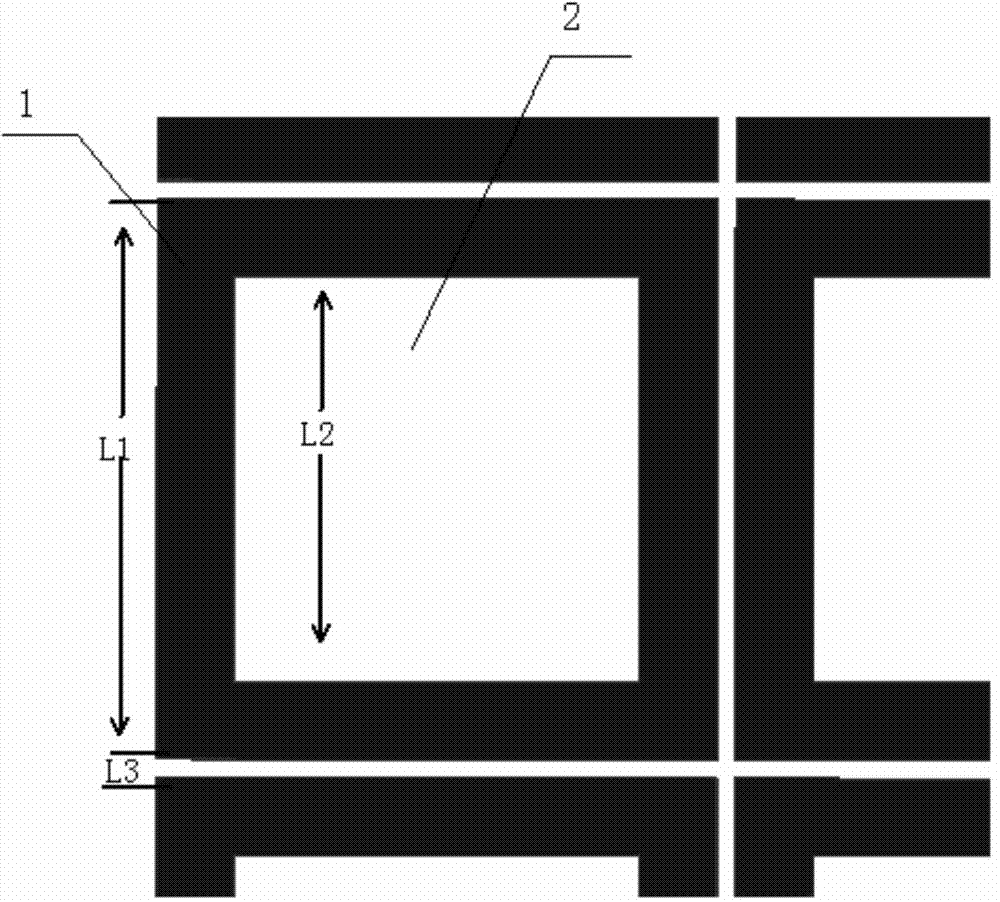

[0023] Such as figure 1 Shown is the overall structure of the frequency selective surface. It includes 100 units 1 and a bottom plate 3. The units 1 are arranged in 10 rows and 10 columns. The units 1 in each row are aligned in the horizontal direction, and the units 1 in each column are aligned in the vertical di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com