A dual-machine parallel device and control method for an emergency DC oil pump starter in a power plant

A technology of starters and main starters, which is applied in the reduction gear of AC motors, starters of single DC motors, motor generators/starters, etc., and can solve problems such as limited anti-overload capacity, easy open circuit or short circuit, etc. Achieve the effects of strong overload resistance, simple structure, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

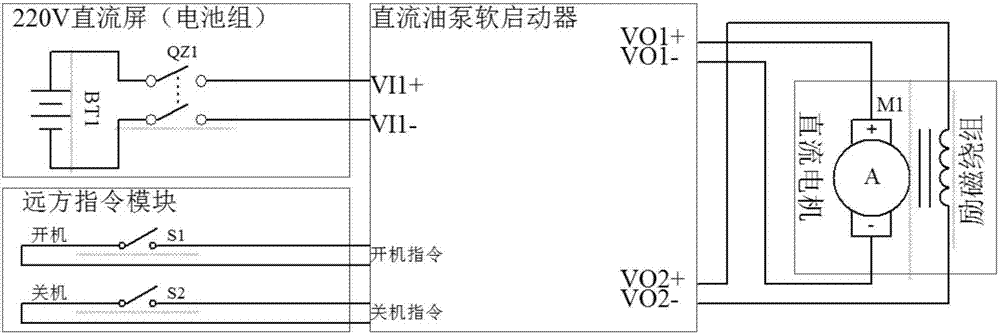

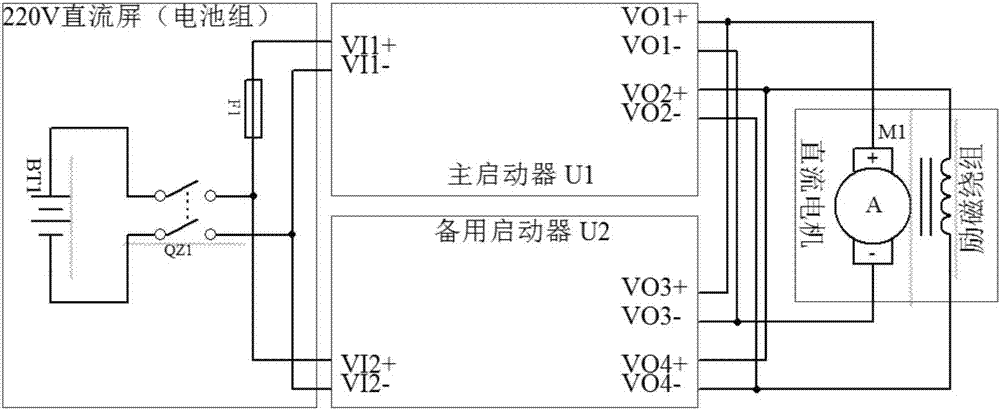

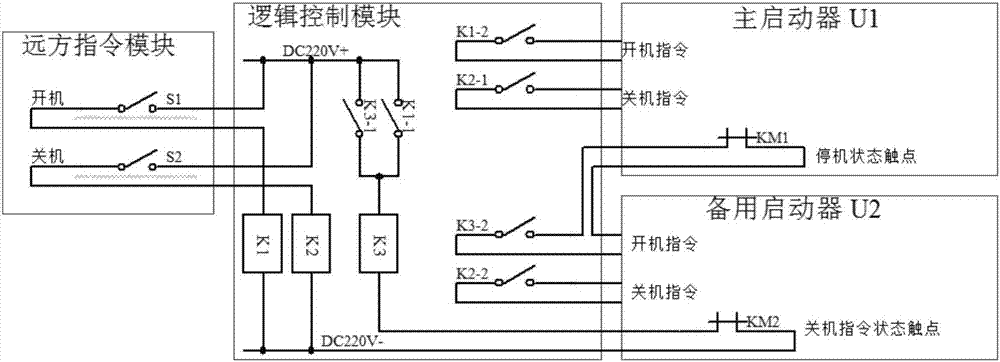

[0049] like Figure 1-3 shown.

[0050] A two-machine parallel device for emergency DC oil pump starters in power plants, including a remote command module, a main starter U1, a backup starter U2 and a logic control module; the main circuit of the main starter U1 and the main circuit of the backup starter U2 are connected in parallel ;The main starter U1 is a BUCK conversion type DC oil pump soft starter. The main starter U1 is equipped with a "stop state" contact KM1, a start-up command interface and a shutdown command interface; the backup starter U2 is a resistive DC oil pump starter. The starter U2 is provided with a "shutdown command state" contact KM2, a power-on command interface and a shutdown command interface; the remote command module is provided with a power-on command contact S1 and a power-off command contact S2; The command contact S2, the "shutdown state" contact KM1, and the "shutdown command state" contact KM2 are respectively connected to the logic control ...

Embodiment 2

[0060] The dual-machine parallel device of the emergency DC oil pump starter of the power plant described in Embodiment 1 is different in that: the main starter U1 is provided with a fuse F1. When the internal short-circuit fault occurs in the BUCK conversion type DC oil pump soft starter, the fuse can be blown quickly to prevent the fault from spreading and the DC screen DC circuit breaker from overcurrent tripping.

Embodiment 3

[0062] The dual-machine parallel device of the emergency DC oil pump starter of the power plant as described in Embodiment 2 is different in that: the time relay K3 controls the coil to be energized and the normally open contact K3-2 is closed after a delay of 4 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com