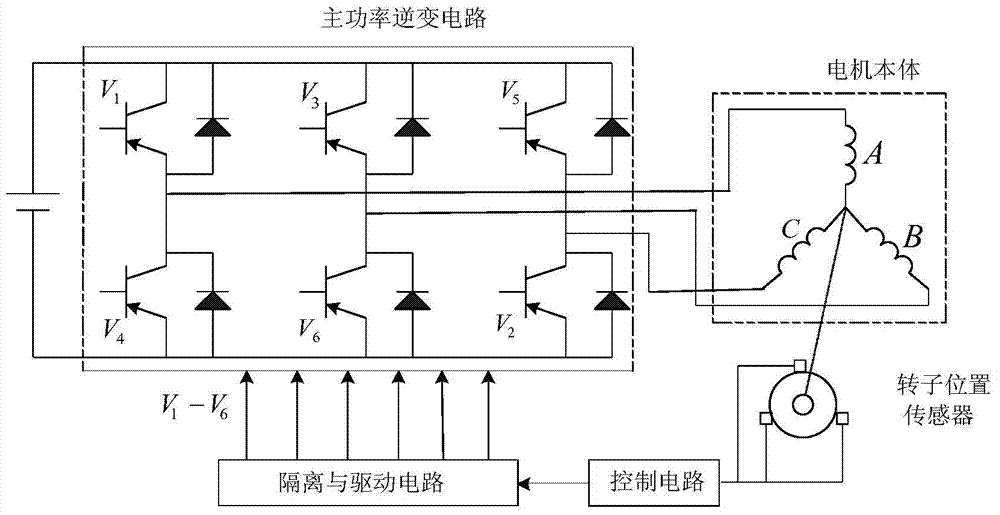

Brushless direct current motor power inverter power-on self-test device and self-test method

A power inverter, brushed DC motor technology, applied in emergency protection circuit devices, measuring devices, measuring electrical variables, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

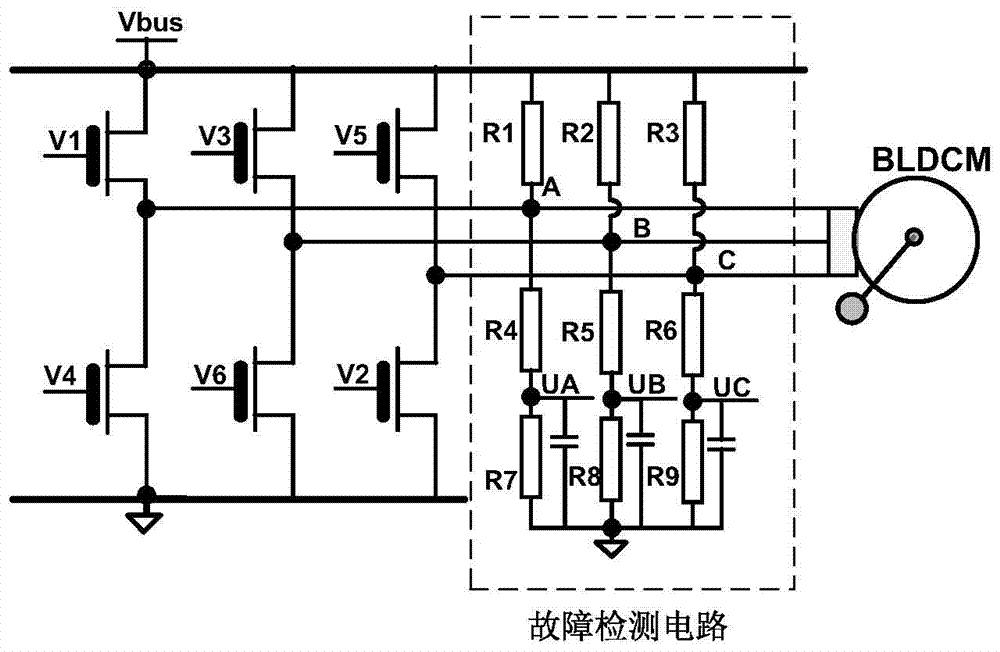

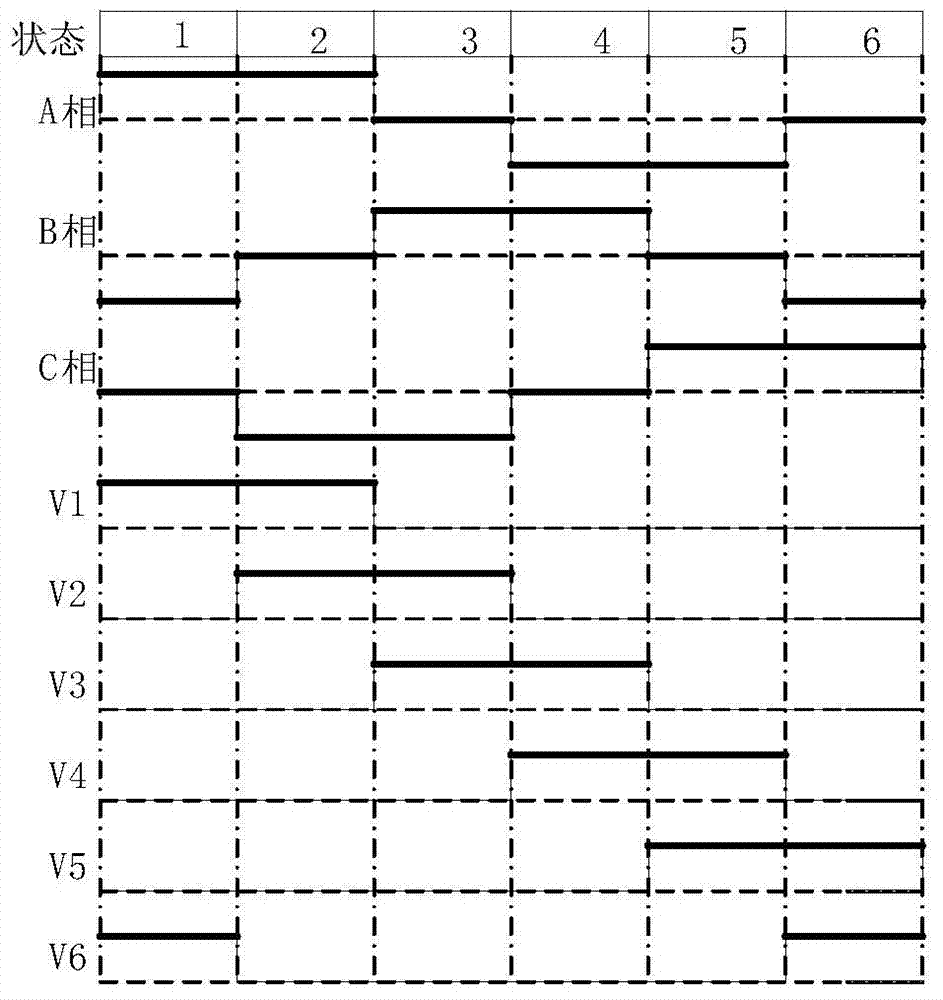

[0050] Specific embodiments: the system used in the experiment is a three-phase six-state brushless DC motor control system, the DSP used is TMS320F2808 of TI Company, the chopping frequency is 25KHz, and the chopping mode is chopping up and down without chopping. figure 2 The terminal voltage detection signals UA, UB, and UC are sent to the AD0, AD1, and AD2 ports of the DSP for detection, and the AD sampling mode is set to sample at the middle of the duty. The power-on self-test algorithm of the power inverter is realized by DSP programming, and the program flow chart is shown in Figure 4 , which will be described in detail below with examples.

[0051] (1) Initialization

[0052] Set the duty cycle for detection, and TestDuty is _IQ(0.05); set the sampling trigger event of the AD module to the sampling mode at the middle of the duty cycle; clear all power inverter-related fault flags to 0.

[0053] (2) Turn off all power tubes of the power inverter

[0054] (3) Read th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com