Cable membrane greenhouse and building method thereof

A cable-membrane and greenhouse technology, which is applied in botany equipment and methods, horticulture, greenhouse cultivation, etc., can solve the problems of high construction cost, poor thermal insulation, complicated and complicated construction technology of greenhouses, and achieve simple and fast opening and closing operations, and improve Airtightness and thermal insulation, and the effect of improving the efficiency of ventilation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

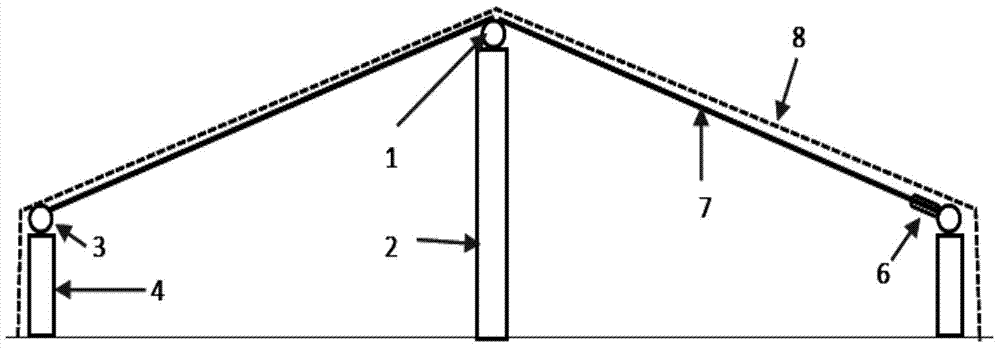

[0128]figure 1 It shows a schematic cross-sectional view of a double-slope cable-membrane greenhouse facade structure constructed by two sets of cable-membrane tension structures and a set of cable-membrane support structures of the present invention.

[0129] The double-slope cable-membrane greenhouse is composed of a cable-membrane support structure 1, a cable-membrane tension structure 3 and a cable-membrane enclosure structure, wherein the cable-membrane enclosure structure is composed of a cable 7 and a plastic film 8 as an integrated structure. The cable-membrane support structure 1 is arranged on a wall or a column 2 . The functions of the wall or column 2 mainly include: one is to form the height space of the cable-membrane greenhouse, and the other is to receive the pressure of the cable-membrane support structure 1 .

[0130] The cable-membrane support structure 1 includes support beams or support cables. The support beams are rigid components made of building materi...

Embodiment 2

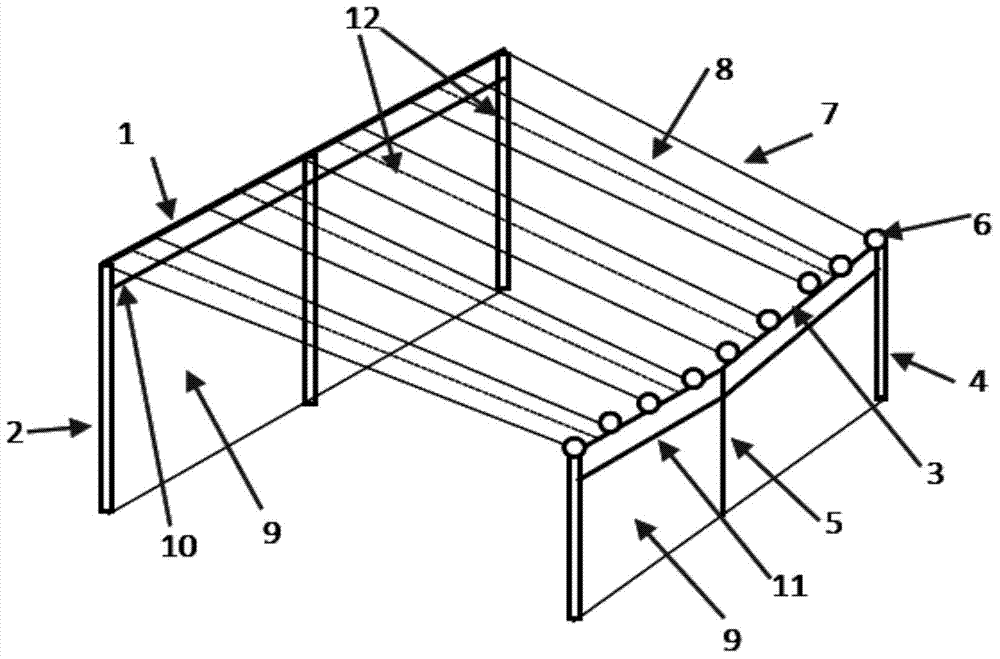

[0133] figure 2 It shows a schematic perspective view of a single-slope cable-membrane greenhouse structure constructed by a set of cable-membrane tension structures and a set of cable-membrane support structures of the present invention.

[0134] The single-slope cable-membrane greenhouse is composed of a cable-membrane support structure 1 , a cable-membrane tension structure 3 and a cable-membrane enclosure structure. The cable-membrane support structure 1 is arranged on a wall or a column 2 to form a height space of the cable-membrane greenhouse. The cable-membrane tension structure 3 is arranged on one side of the cable-membrane support structure 1, is as long as the cable-membrane support structure 1, is parallel to the cable-membrane support structure 1, and is lower than the cable-membrane support structure 1; the cable-membrane tension structure 3 is fixed on the On the second wall or the second column or the second anchor rod 4 and the anchor cable 5, the connection...

Embodiment 3

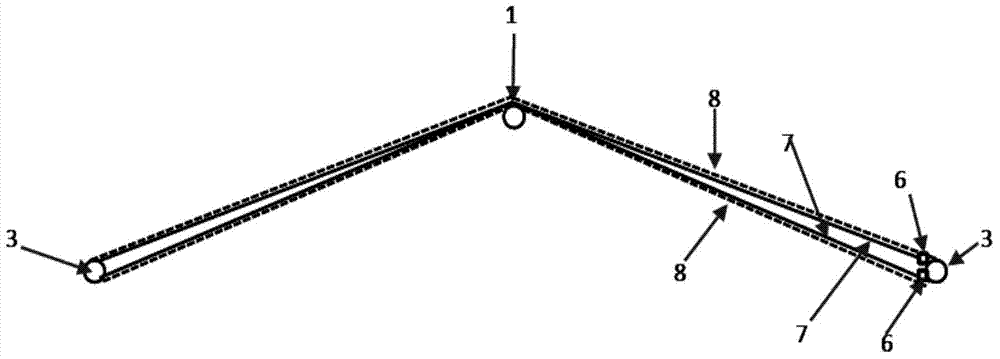

[0138] image 3 It shows a schematic cross-sectional view of a double-slope cable-membrane greenhouse roof structure constructed by two sets of cable-membrane tension structures and a set of cable-membrane support structures according to the present invention, which is a double-layer cable-membrane enclosure structure.

[0139] In the above-mentioned double-layer cable-membrane enclosure structure, each group of cable-membrane tension structures 3 and cable-membrane support structures 1 only includes one cable-membrane tension structure and one cable-membrane support structure, and the two sets of cable-membrane tension structures 3 are located in one Group the two sides of the cable-membrane support structure 1. The cable-membrane tension structure 3 is lower than the cable-membrane support structure 1 , and the cable-membrane tension structure 3 is parallel to and equal in length to the cable-membrane support structure 1 . The cable-membrane enclosure structure is a composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com