Horizontal green walnut peeling machine

The technology of green walnut and peeling machine, which is applied in the field of agricultural machinery, can solve the problems of unsatisfactory peeling of walnut varieties, difficulty in peeling green walnut, etc., and achieve the effects of long stroke, low breaking rate and wide channel width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

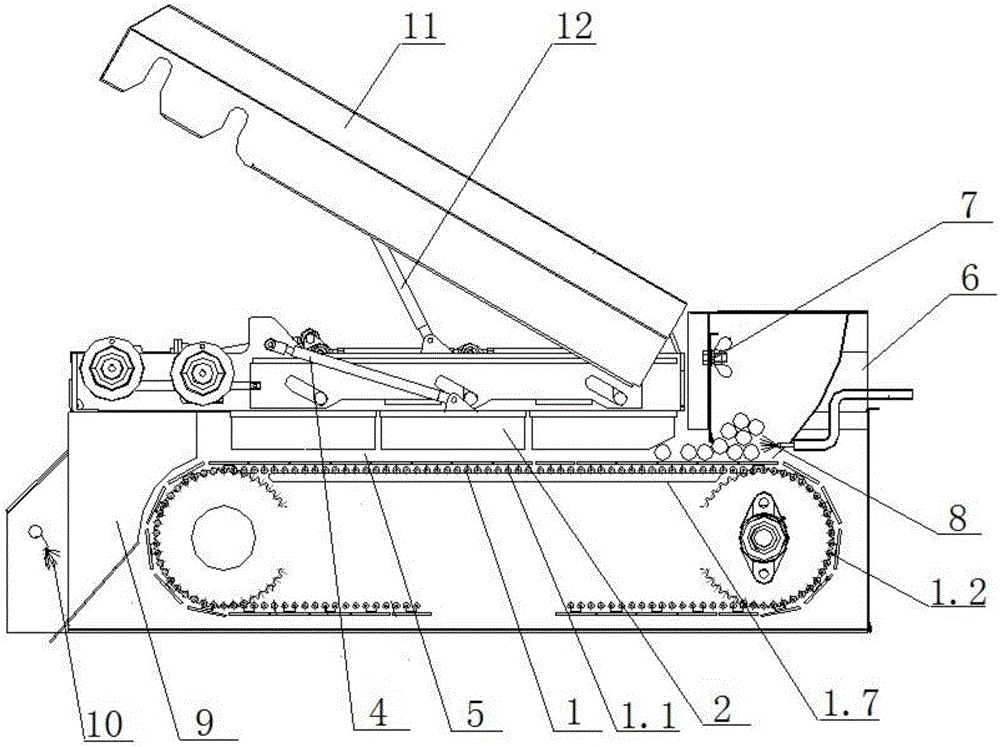

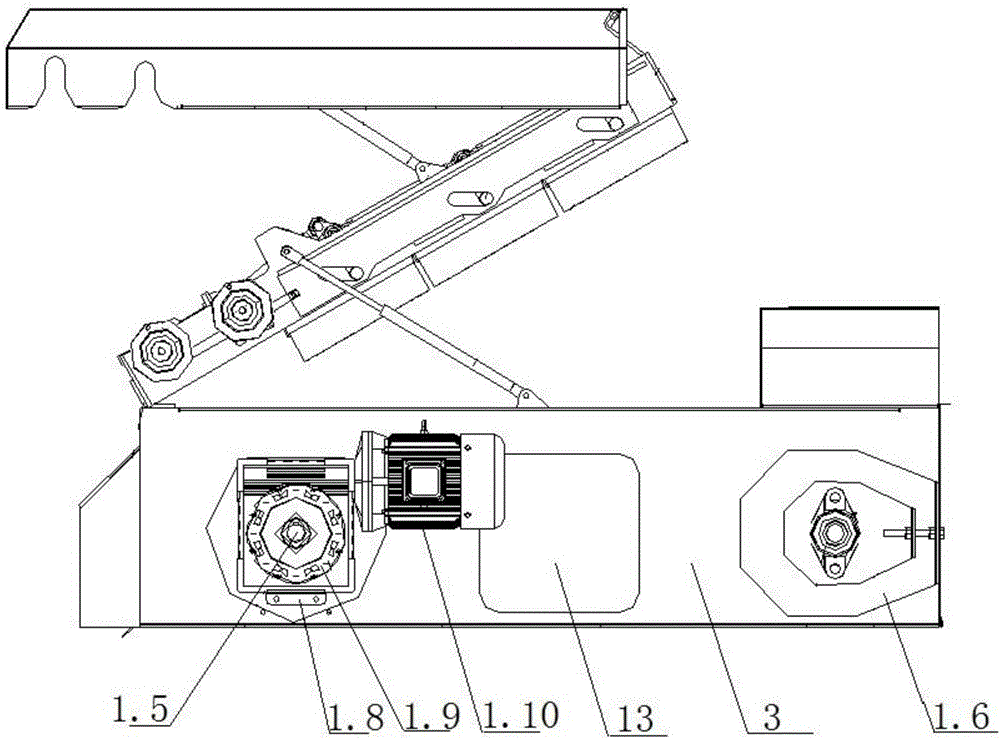

[0031] Embodiment 1: a kind of horizontal green walnut peeling machine, mainly comprises the chain conveying and cutting mechanism 1 of the bottom and the scrubbing brush mechanism 2 of the upper part, it is characterized in that: the chain conveying and cutting mechanism 1 of the lower part comprises chain 1.1, sprocket wheel 1.2, horizontal long steel plate 1.3 and blade 1.4, the chain 1.1 is driven by the front and rear sprockets 1.2 below, the sprocket 1.2 is fixed on the transmission shaft 1.5, and the rear transmission shaft 1.5 is fixed on the rear bearing installation plate 1.6 through bearings , the bearing mounting plate 1.6 is fixed on the supporting plates 3 on both sides, the chain 1.1 is fixed with a horizontal long steel plate 1.3, the horizontal long steel plate 1.3 is fixed with a blade 1.4, and the upper side of the chain 1.1 has a chain bracket 1.7 for top The chain 1.1 on the upper side hangs down, the motor reducer 1.9 is installed on the side of the suppor...

Embodiment 2

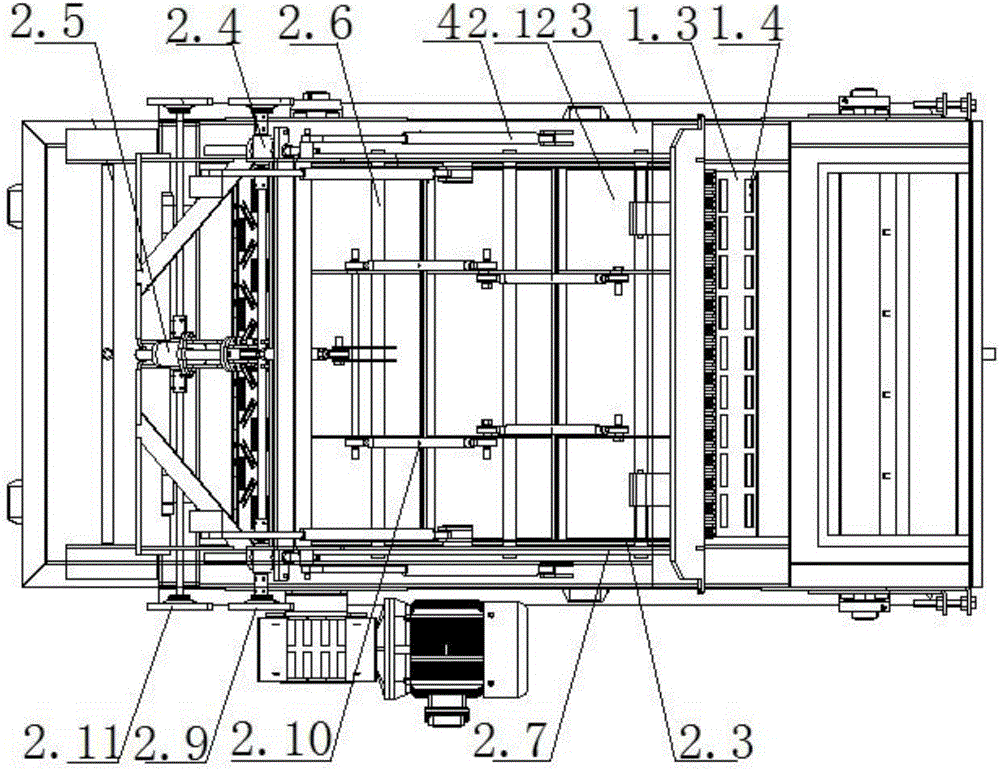

[0034] Embodiment 2: A kind of horizontal green walnut peeling machine, mainly comprises the chain conveying and cutting mechanism 1 of the bottom and the scrubbing brush mechanism 2 of the upper part, it is characterized in that: the chain conveying and cutting mechanism 1 of the lower part comprises chain 1.1, sprocket wheel 1.2, horizontal long steel plate 1.3 and blade 1.4, the chain 1.1 is driven by the front and rear sprockets 1.2 below, the sprocket 1.2 is fixed on the transmission shaft 1.5, and the rear transmission shaft 1.5 is fixed on the rear bearing installation plate 1.6 through bearings , the bearing mounting plate 1.6 is fixed on the supporting plates 3 on both sides, the horizontal long steel plate 1.3 is fixed on the chain 1.1, the blade 1.4 is fixed on the horizontal long steel plate 1.3, and the chain bracket 1.7 is fixed below the chain 1.1 on the upper side for The chain 1.1 on the upper side of the jacking is sagging, the side of the support plate 3 is i...

Embodiment 3

[0038] Embodiment 3: A kind of horizontal green walnut peeling machine, mainly comprises the chain conveying and cutting mechanism 1 of the lower part and the scrubbing brush mechanism 2 of the upper part, it is characterized in that: the chain conveying and cutting mechanism 1 of the lower part comprises chain 1.1, sprocket wheel 1.2, horizontal long steel plate 1.3 and blade 1.4, the chain 1.1 is driven by the front and rear sprockets 1.2 below, the sprocket 1.2 is fixed on the transmission shaft 1.5, and the rear transmission shaft 1.5 is fixed on the rear bearing installation plate 1.6 through bearings , the bearing mounting plate 1.6 is fixed on the supporting plates 3 on both sides, the chain 1.1 is fixed with a horizontal long steel plate 1.3, the horizontal long steel plate 1.3 is fixed with a blade 1.4, and the upper side of the chain 1.1 has a chain bracket 1.7 for top The chain 1.1 on the upper side hangs down, the side of the support plate 3 is installed with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com