Dry heat sterilization system

A technology of dry heat sterilization and hot air, applied in heating and other directions, can solve problems such as incomplete sterilization, achieve the effect of solving incomplete sterilization and ensuring the sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

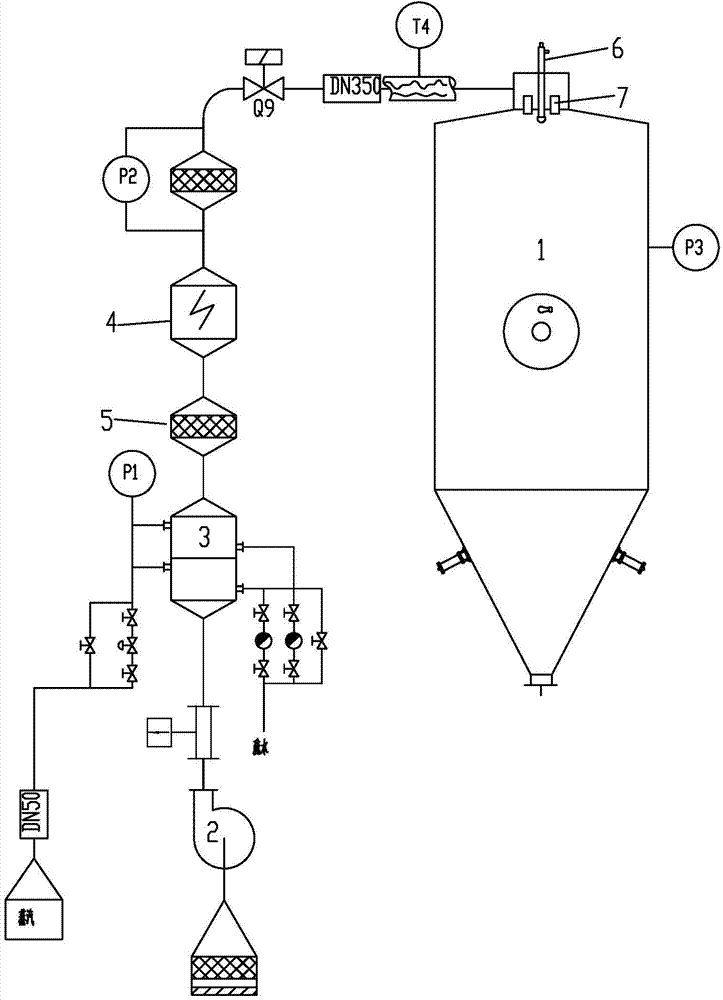

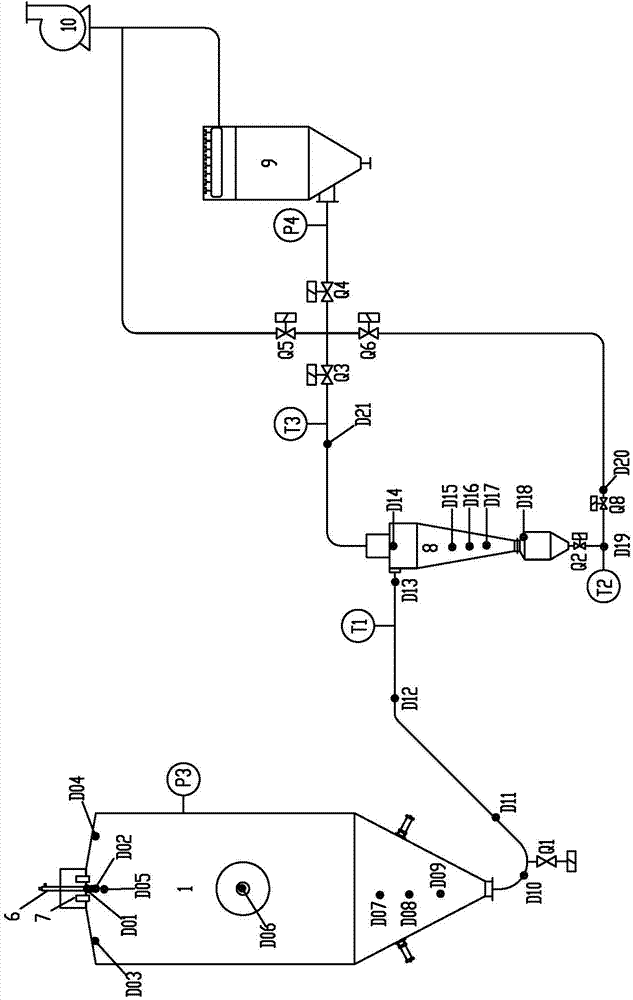

[0020] Such as figure 2 As shown, a spray drying equipment includes a spray drying tower 1, a cyclone separator, a bag filter 9 and an induced draft fan 10; , the central position on the top of the tower is provided with a hot air distributor 7 and a two-fluid atomizer 6, and the two-fluid atomizer 6 vertically runs through the hot air distributor 7, and is located in the spray drying tower 1 tower body. One end of the two-fluid atomizer 6 is provided with a pressure spray nozzle, and feed liquid and sterile compressed air are entered into one end of the two-fluid atomizer 6 positioned outside the hot air distributor 7; the tower body is provided with a pressure gauge P3; There is an air hammer on the bottom side surface of the conical tower, and the air hammer is connected with ordinary compressed air to vibrate, so that the material on the bottom surface of the conical tower enters the discharge port at the bottom of the conical tower, and the discharge port passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com