Process system suitable for carrying out granulating molding by recycling coal slime dust

A technology of dust recovery and process system, which is applied in the direction of liquid separation into beads and granulation, which can solve the problems of environmental protection industry, pollution industry, etc., and achieve the effect of solving the problem of dust pollution and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the examples.

[0035] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The reagents or instruments used were not indicated by the manufacturer, and they were all conventional products that could be purchased.

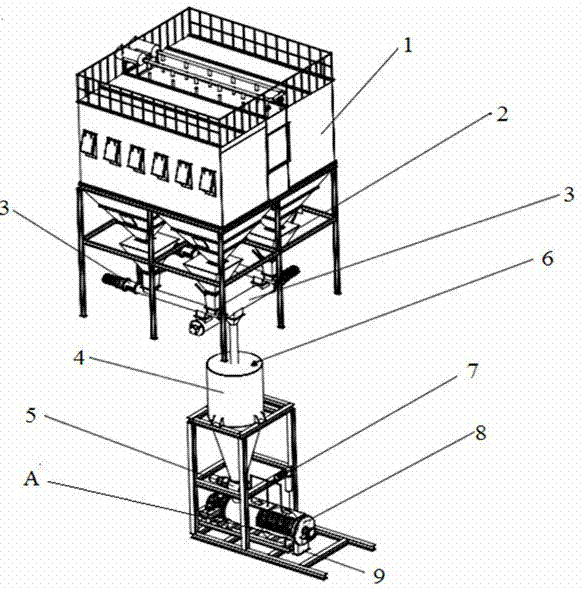

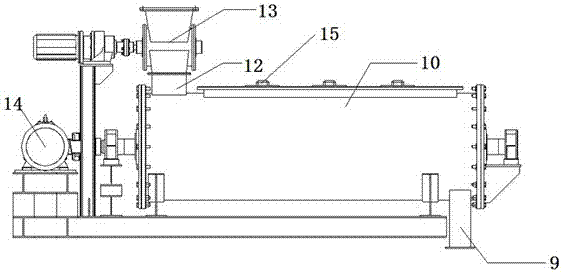

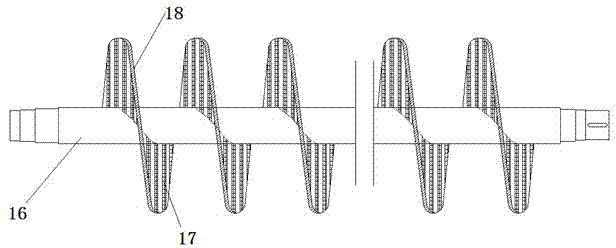

[0036] like Figure 1-Figure 3 As shown, a process system suitable for coal slime dust recovery for granulation molding, including dust collector 1, ash collecting bucket 2, converging screw conveyor 3, coal slime dust buffer bin 4, ash volume regulating valve 5, radar material Position meter 6, granulator 7 and atomizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com