Wet type grinding wheel assembly

A wet type, grinding wheel technology, applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of wasting water resources, grinding wheel water splashing, etc., to reduce grinding sparks and grinding Cut dust, save water resources, and avoid water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

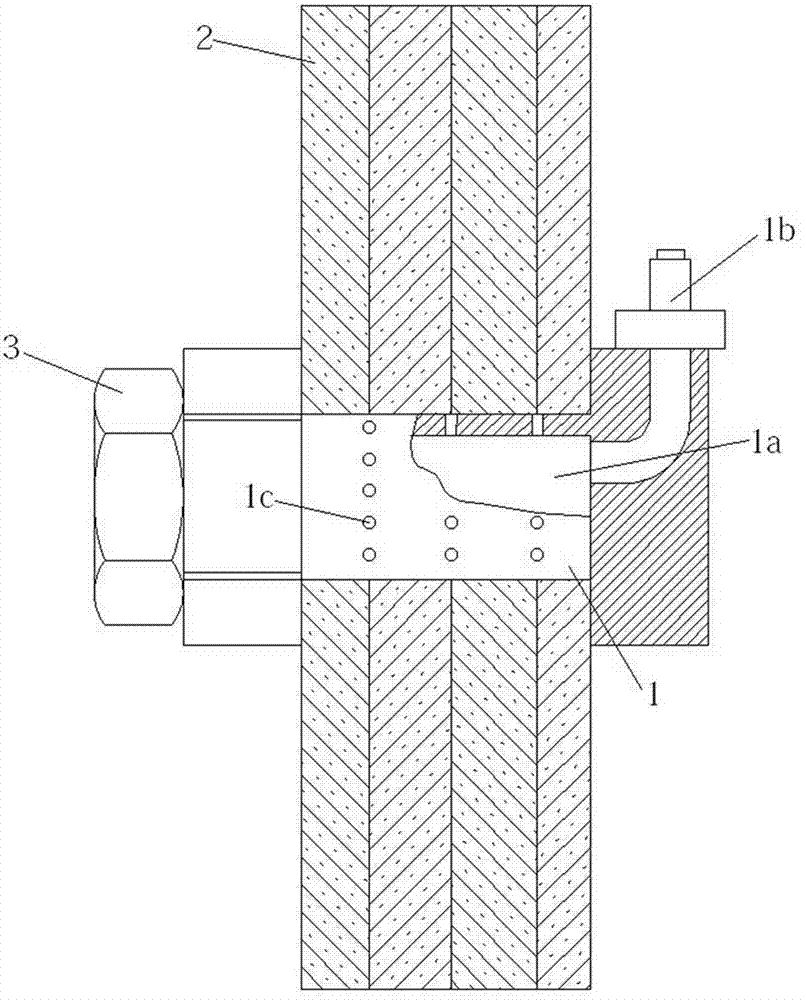

[0011] Symbols in the drawings: grinding wheel shaft 1, water storage cavity 1a, faucet 1b, water guide hole 1c, grinding wheel sheet 2, nut 3.

[0012] A wet type grinding wheel assembly, comprising a grinding wheel shaft 1, a grinding wheel piece 2, the grinding wheel piece 2 is fixedly connected to the grinding wheel shaft 1, the center of the body of the grinding wheel shaft 1 is a water storage cavity 1a, and the water storage cavity 1a is cylindrical. The grinding wheel shaft 1 is also provided with a water nozzle 1b, which communicates with the water storage cavity 1a, and the water storage cavity 1a is filled with water through the water nozzle 1b. After adding water, the water nozzle 1b is sealed.

[0013] The grinding wheel shaft 1 is a stepped shaft whose diameter at one end is larger than that at the middle, and the body of the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com