Indoor dedusting room of machine shop

A technology of mechanical workshops and fans, which is applied in the direction of combined devices, dispersed particle separation, grinding/polishing equipment, etc. It can solve problems such as poor operating environment, heavy workload, troublesome transfer of workpieces, etc., and achieve compact structure and flow resistance. Low, good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

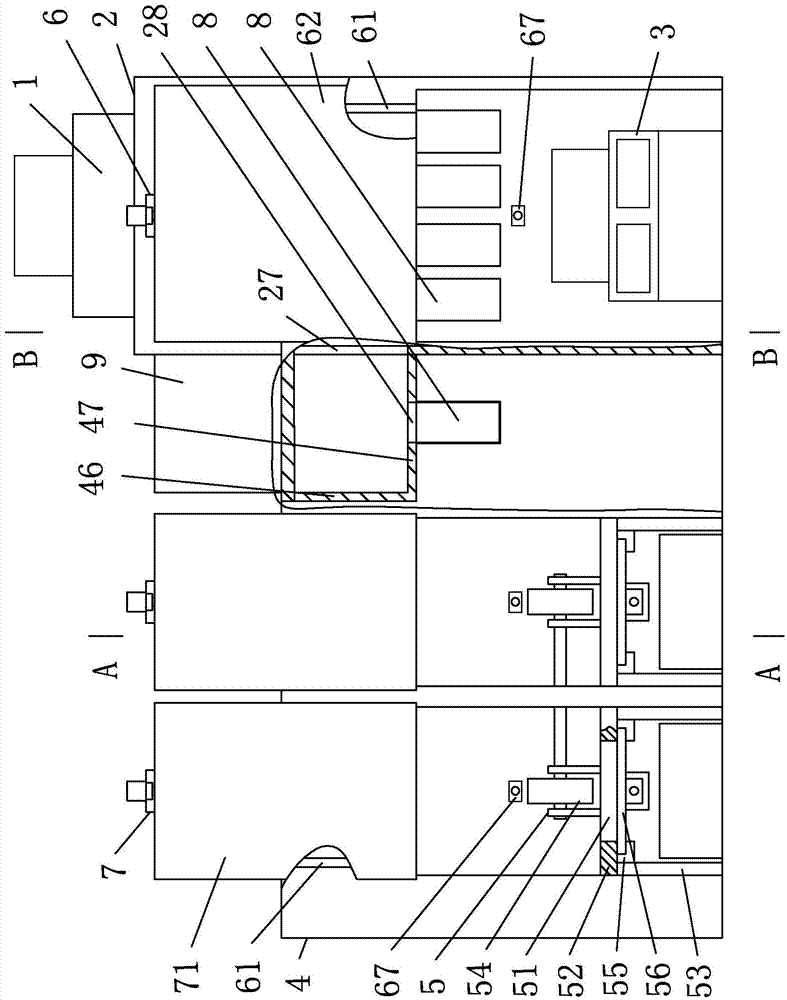

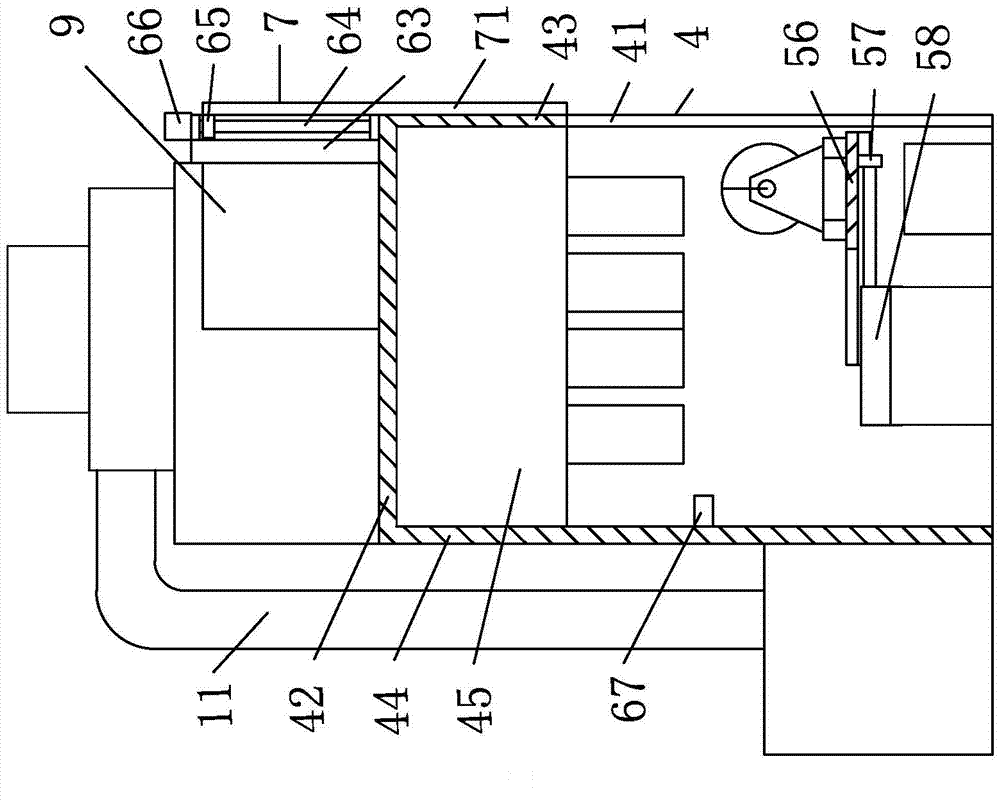

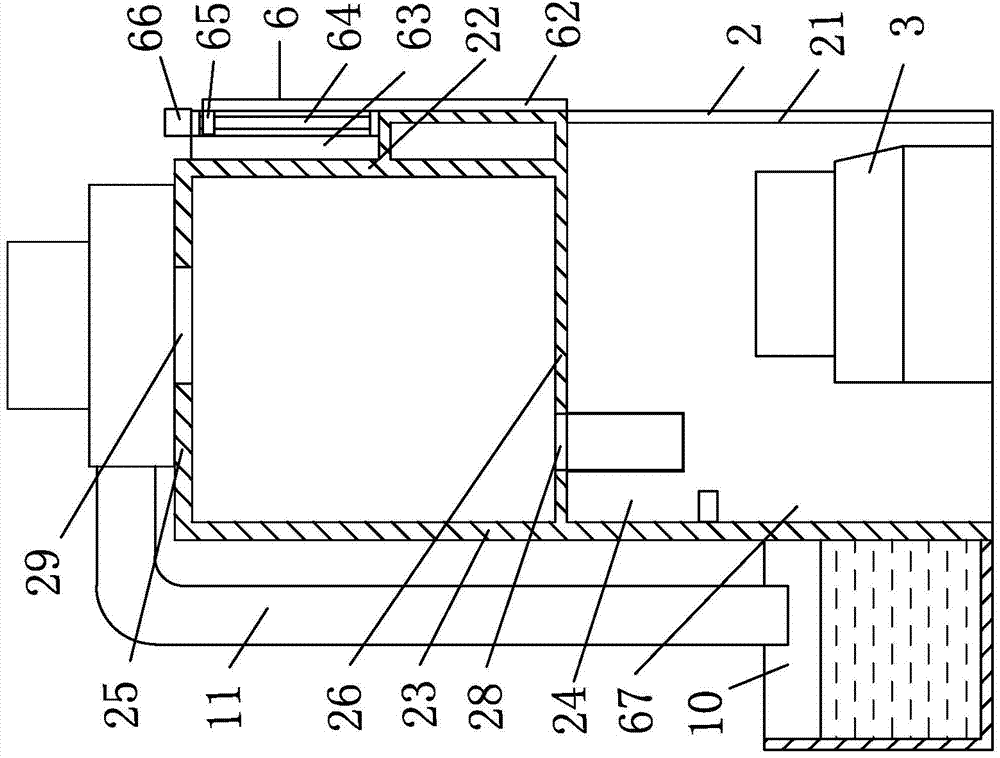

[0016] as attached figure 1 To attach image 3 Shown: an indoor dust removal room of a mechanical workshop, including a grinding room 2 with a grinding door opening 21, a grinder 3 located in the grinding room 2 and inside a grinding door opening 21, and a grinding room with two grinding door openings 41 4. Two grinding devices 5 located in the grinding room 4 and each inside a grinding door opening 41, two dust removal devices respectively located in the grinding room 2 and grinding room 4, and the number of grinding rooms is the same as the number of grinding door openings 21 Air intake adjustment assembly 6, two grinding room air intake adjustment assemblies 7 with the same number as the number of 41 polished door openings, fan 1.

[0017] The grinding room 2 includes a front wall plate 22, a rear wall plate 23, two side wall plates 24, a top plate 25 with a top h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com